Ring-type floating piston single-cylinder shock absorber

A floating piston and shock absorber technology, used in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as short service life, poor performance, and increased friction, so as to ensure service life and use effect, probability of noise reduction, effect of reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

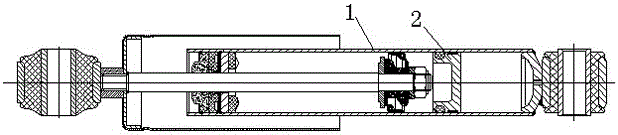

[0022] The present invention includes a cylinder body 1 and an aluminum floating piston 2 arranged inside the cylinder body 1, and the aluminum floating piston 2 moves up and down along the inner wall of the cylinder body 1;

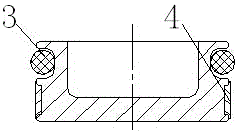

[0023] A sealing ring 3 and a guide piston ring 4 are arranged circumferentially between the cylinder body 1 and the aluminum floating piston 2 .

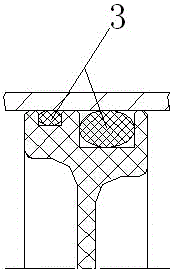

[0024] The seal ring 3 is arranged on the top of the guide piston ring 4, and the seal ring 3 and the guide piston ring 4 protrude from the aluminum floating piston 2.

[0025] The aluminum floating piston 2 is provided with an empty groove for placing the sealing ring 3 and the guide piston ring 4 .

[0026] The sealing ring 3 and the guide piston ring 4 are arranged symmetrically along the axis of the floating piston 2 .

[0027] The working process of the present invention is that under normal conditions, the seal ring 3 and the guide piston ring 4 are positioned in the hollow groove and slightly protrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com