Pressure maintaining valve with variable opening pressure

A technology for cracking pressure and pressure-stabilizing valves, which is applied to valve devices, safety valves, balance valves, etc. It can solve problems such as relatively large pressure range changes, limited spring stiffness, and low experimental efficiency, and achieves convenient installation, wide adjustment range, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

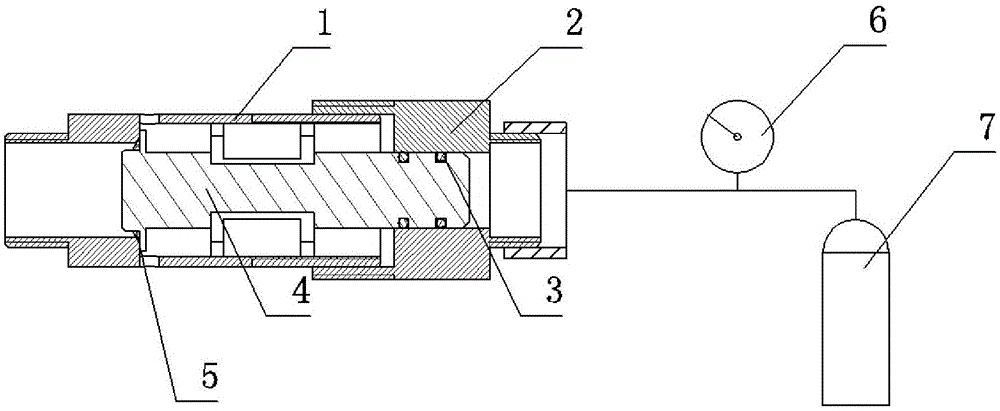

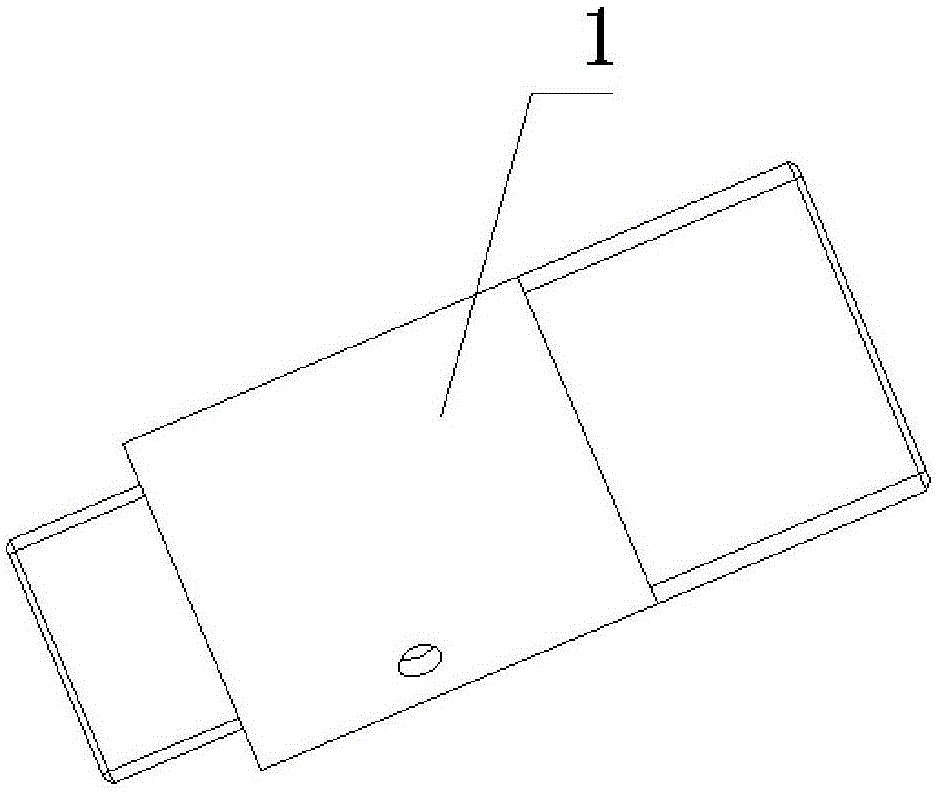

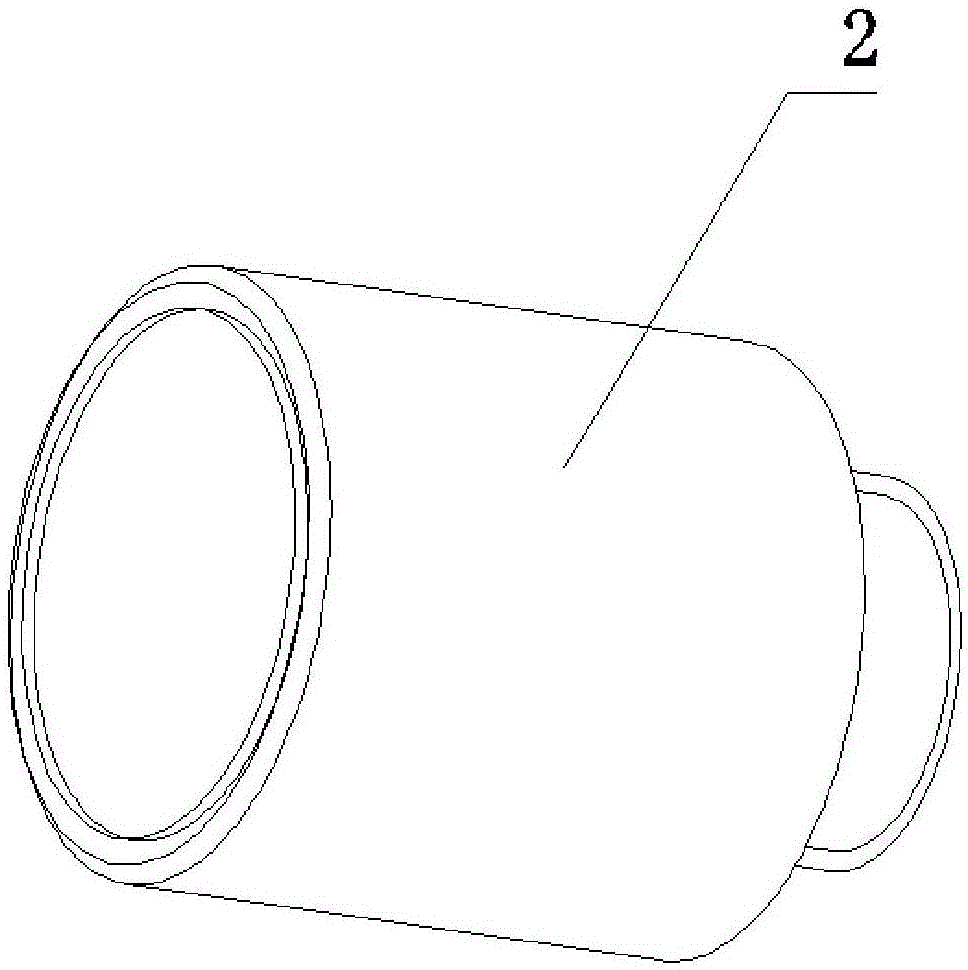

[0024] A pressure stabilizing valve with variable opening pressure includes a working end housing 1, a pressure source end housing 2, a sealing rubber ring 3, a core rod 4, an inclined rubber plug 5, a safety valve 6 and a high-pressure gas cylinder 7. The working end housing 1 is fixedly connected to the pressure source end housing 2, the other end of the pressure source end housing 2 is fixedly connected to the safety valve 6, the safety valve 6 is fixedly connected to the high-pressure gas cylinder 7, and one end of the core rod 4 is arranged at In the working end housing 1, the other end is arranged in the pressure source end housing 2, the end of the core rod 4 located in the pressure source end housing 2 is provided with a sealing rubber ring 3, and the core rod 4 is arranged in the working end housing 1. An inclined rubber plug 5 is provided at one end of the inner side.

[0025] The working end housing 1 includes a first cylinder, a second cylinder, and a third cylinder c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com