Cooling tower

A cooling tower and tower technology, applied in the field of cooling towers, can solve the problems of nozzle blockage, entry, and poor atomization effect of cooling water, so as to ensure the cooling effect and reduce the probability of blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

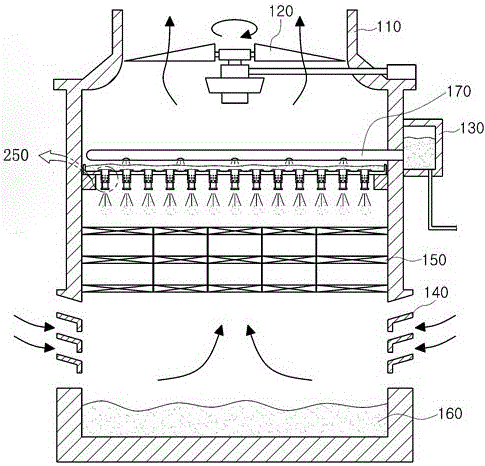

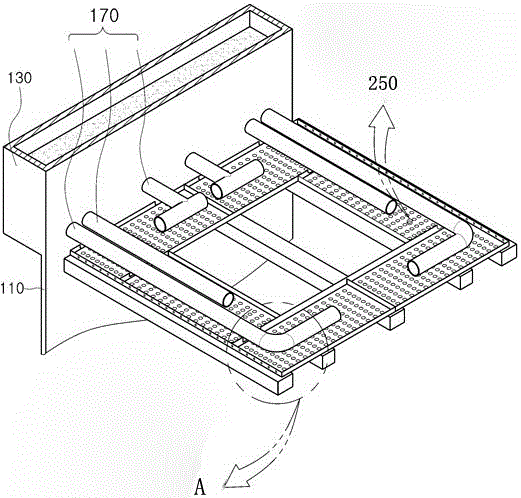

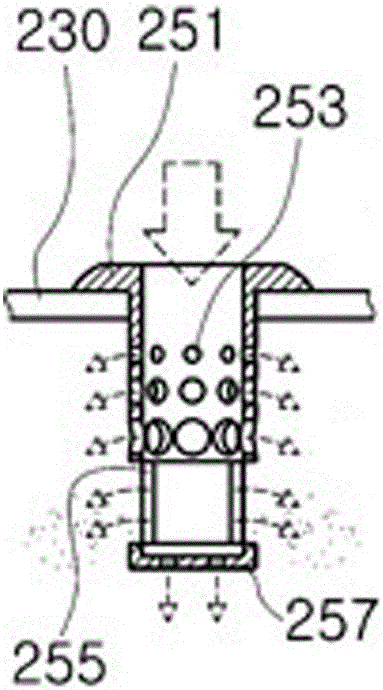

[0022] The reference signs in the drawings of the description include: cooling tower body 110, fan 120, water storage tank 130, air inlet 140, packing 150, cooling water 160, water inlet pipe 170, water baffle 230, nozzle 250, water baffle bracket 270, shower nozzle 251, water spray hole 253, rectangular water spray hole 255, water leakage hole 257, nozzle water inlet 259.

[0023] Such as figure 1 As shown, this embodiment provides a cooling tower, including a cooling tower body 110, a fan 120, a water storage tank 130, fillers 150 and nozzles 250, the top of the cooling tower body 110 is provided with an air outlet, and the fan 120 is installed at the air outlet , the two sides of the lower part are provided with air inlets 140 . The water storage tank 130 is welded on the cooling tower body 110, the water inlet pipe 170 is installed in the cooling tower body 110, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com