Cylindrical surface radius measuring method based on three-dimensional vision

A technology of three-dimensional vision and radius measurement, which is applied in the direction of measuring devices, instruments, complex mathematical operations, etc., can solve the problems of incompleteness, inaccuracy, and inability to realize position error measurement and analysis, and achieve strong anti-noise ability and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

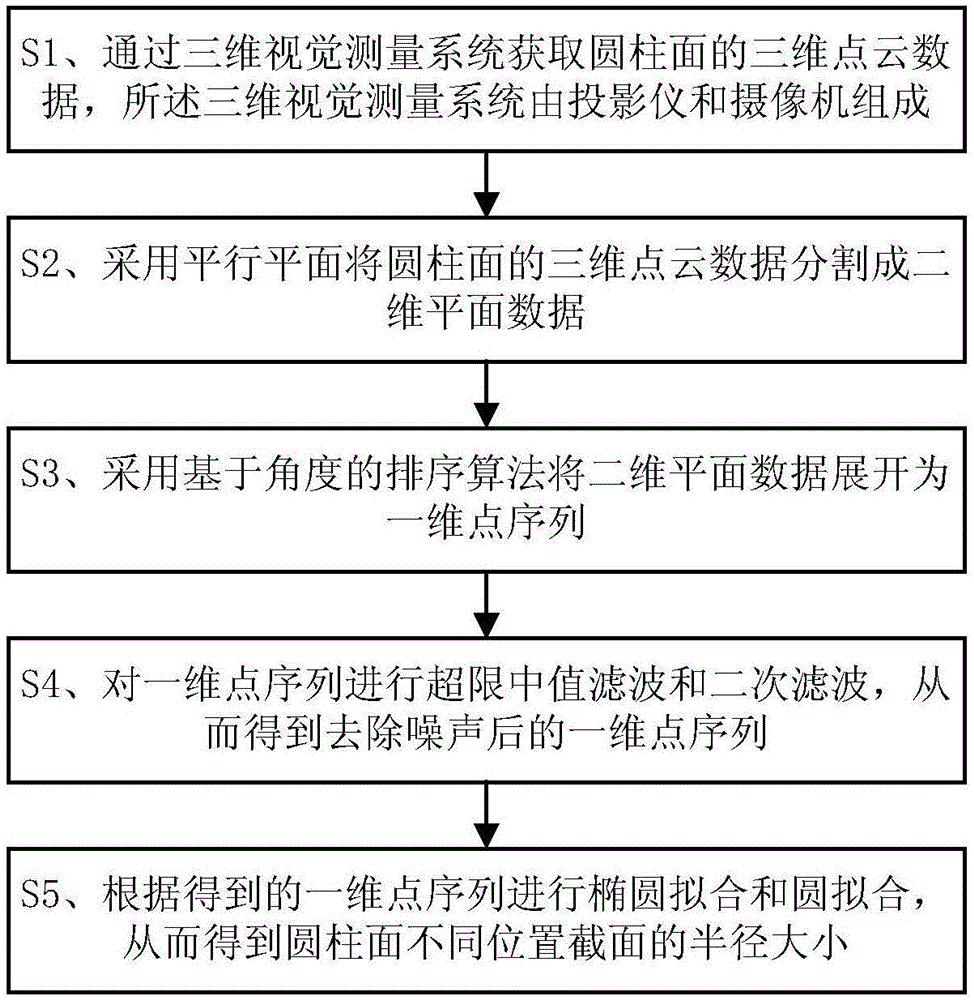

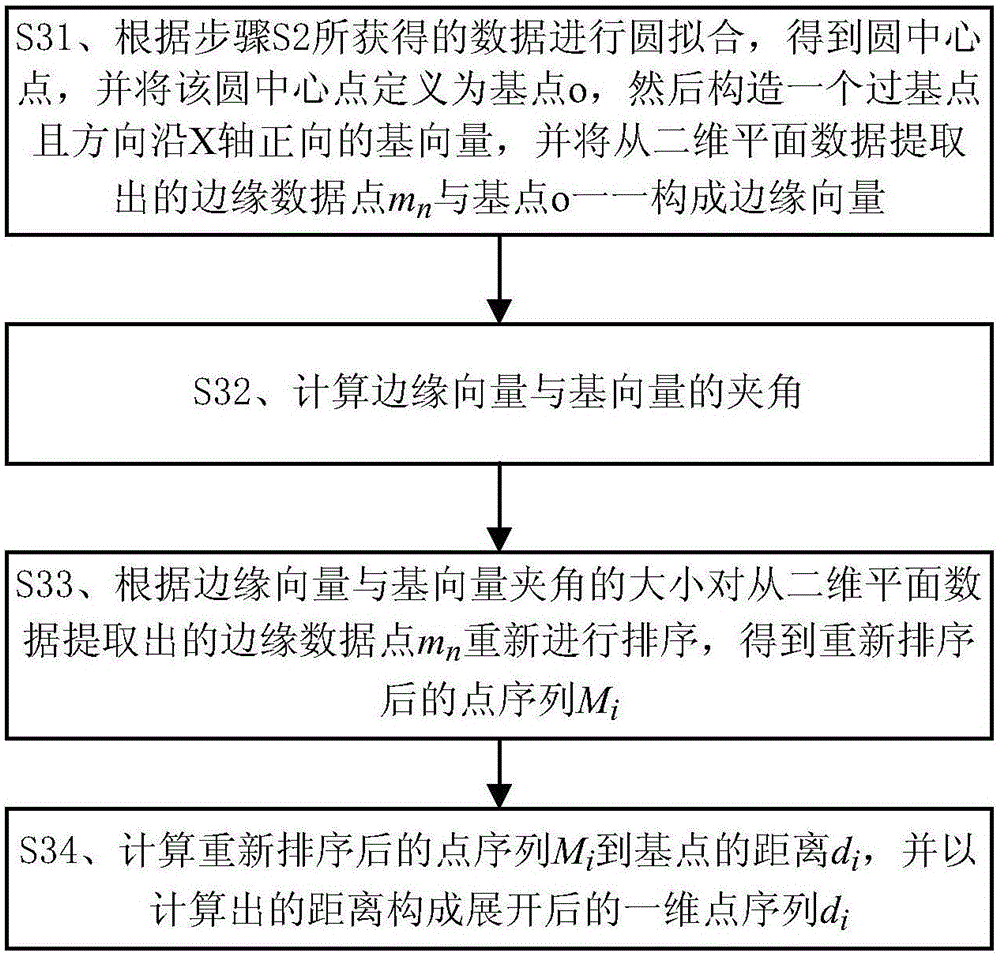

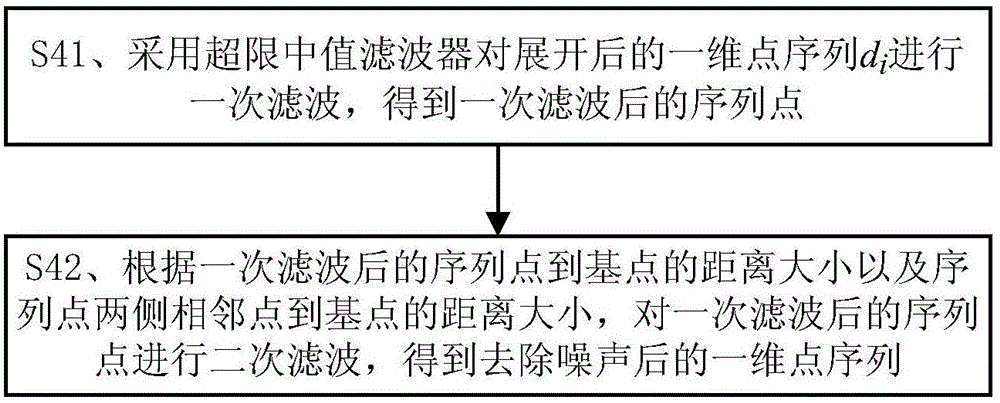

[0078] The main implementation process involved in the method for measuring the radius of a cylindrical surface based on three-dimensional vision in this embodiment includes the following aspects:

[0079] (1). Acquire 3D point cloud data.

[0080] In this embodiment, cameras and projectors are used to build a 3D visual measurement system based on stripe structured light and active stereo vision technology. The schematic diagram of the built system and the process of obtaining 3D point cloud data are as follows: Figure 5-1 and Figure 5-2 shown. After the system calibration is completed, the computer controls the camera to collect and decode the deformed fringe pattern first, then the absolute phase value at each point can be obtained according to the decoded deformed 3D point cloud data of the measured object.

[0081] (2). Data segmentation.

[0082] In order to reduce computational complexity, after obtaining the 3D point cloud data, this embodiment needs to segment th...

Embodiment 2

[0092]The direction of the central axis of the cylindrical surface point cloud data obtained by the 3D visual measurement system is random. This embodiment assumes that the specific process of the cylindrical surface radius measurement algorithm is as follows: Figure 12 Shown: First, use the 3D visual measurement system to obtain the point cloud data of the cylindrical surface; then, use a set of parallel planes to divide the point cloud data into multiple sets of 2D plane data, and use the angle-based sorting algorithm and the over-limit median The filter performs noise filtering, followed by ellipse fitting. However, since the central axis of the cylindrical surface still has a certain angle with the X axis, the accuracy of the obtained plane data is not high. In order to obtain higher-precision two-dimensional plane data, in this embodiment, the central point fitted by the ellipse is fitted with a straight line in space, and then the fitted straight line and the three-dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com