A waste gas collection and treatment device with detection function

A technology of waste gas collection and treatment device, applied in combustion methods, dispersed particle filtration, lighting and heating equipment, etc., can solve the problems of lack of corresponding adjustment treatment, high consumption speed of activated carbon, and high enterprise cost, and achieves increased detection function, improved Service life, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

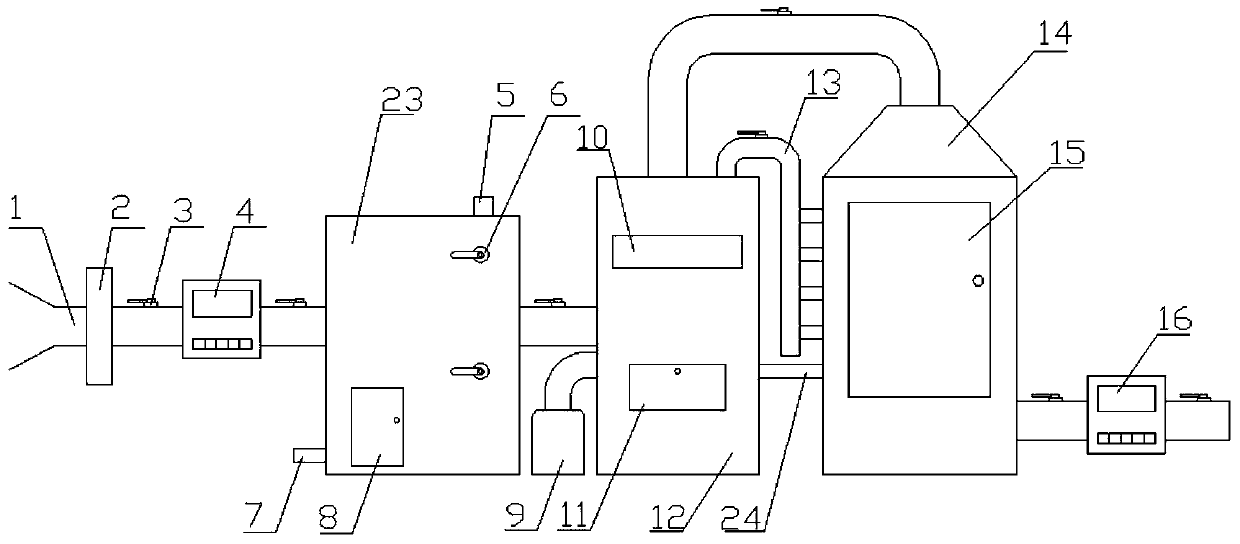

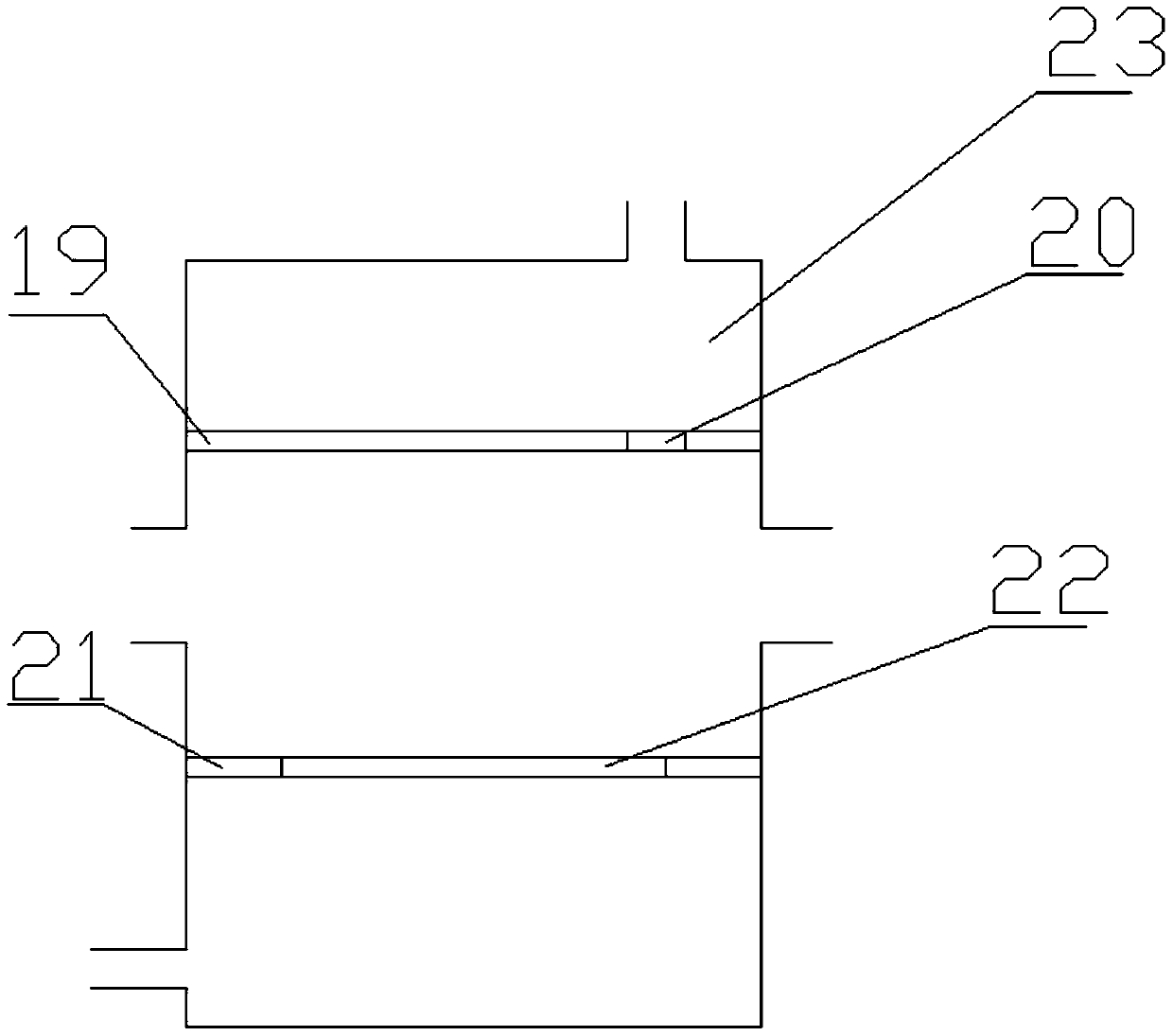

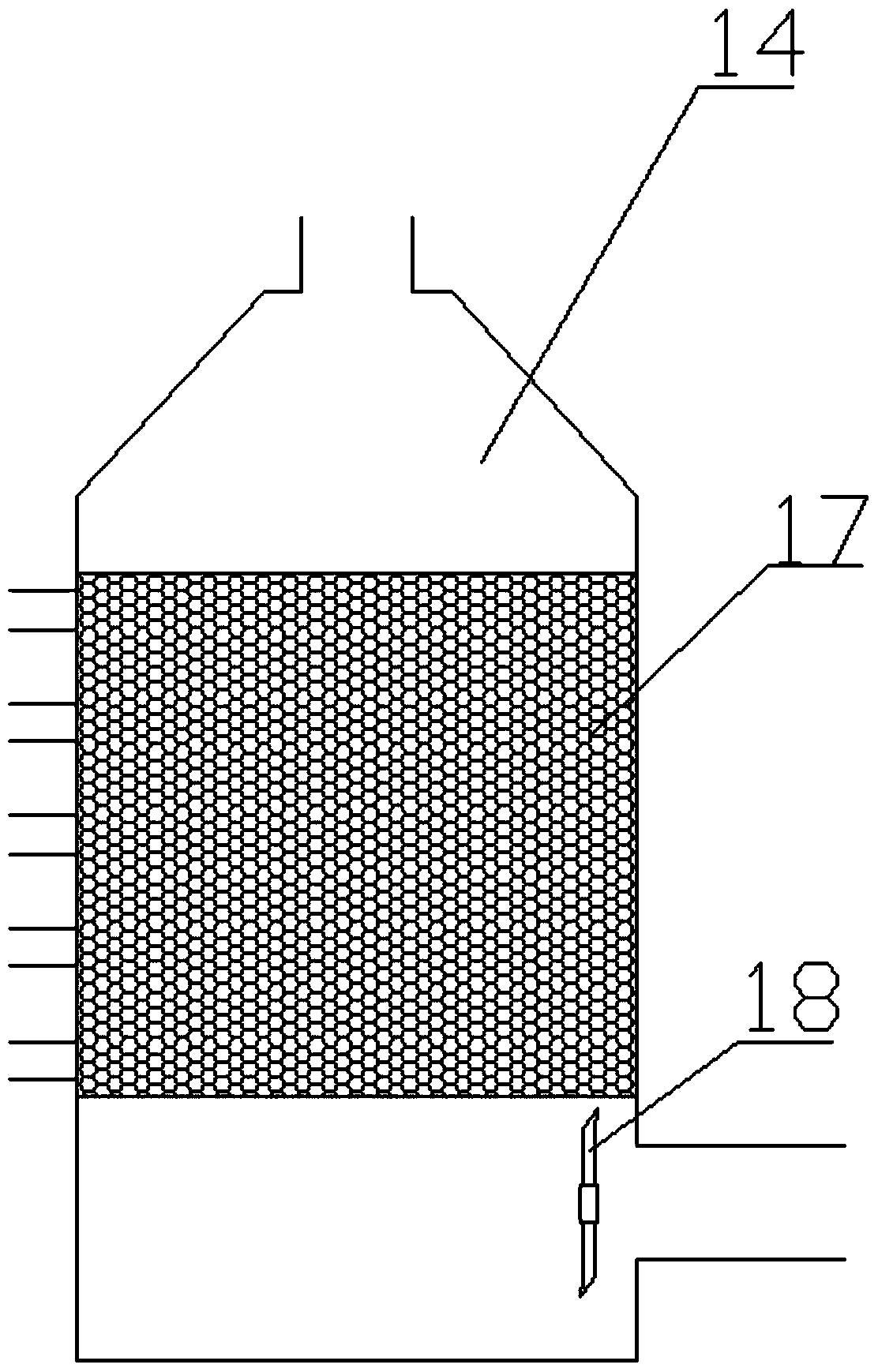

[0028] As shown in the figure, an exhaust gas collection and treatment device with detection function is characterized in that it includes an air intake pipe 1, a coarse filter 2 is provided at the front end of the air intake pipe 1, and a gas detector is provided behind the coarse filter 2 4. A reaction chamber 23 is arranged behind the gas detector, and a feed pipe 5 is arranged on the upper part of the reaction chamber 23, which is flexibly connected with the reaction chamber 23. Two reaction chamber valves 6 are arranged on one side of the reaction chamber 23, The lower part of one side of the reaction chamber 23 is provided with a waste door 8 and a waste liquid pipe 7, the rear of the reaction chamber 23 is provided with a combustion furnace 12, and the upper part of one side of the combustion furnace 12 is provided with an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com