Roller dismounting device for sizing mill and dismounting method

A sizing machine and roll technology, applied in metal rolling, metal rolling, metal rolling stands, etc., can solve problems such as inapplicability to production sites, and achieve the effects of easy operation and maintenance, large transformation potential, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

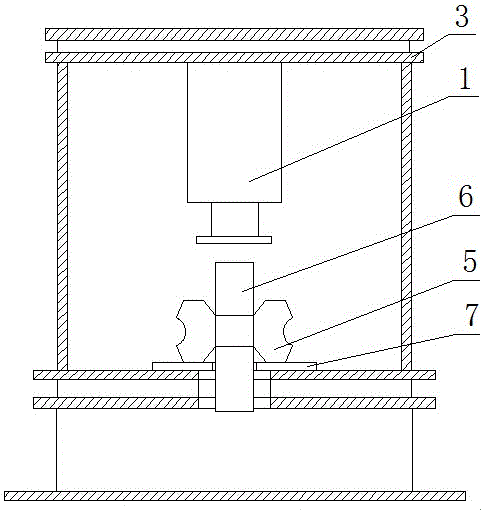

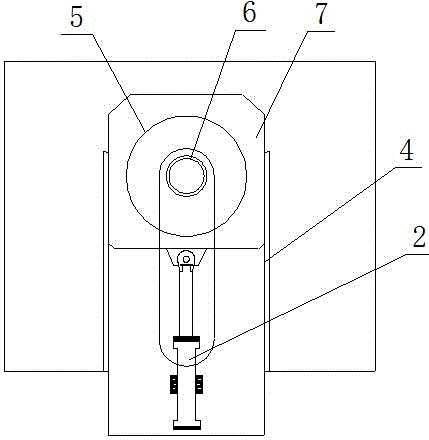

[0020] see Figure 1~2 , a roll dismounting device for a sizing mill, comprising a pressing device, a push-pull device and a frame 3; The hydraulic cylinder 1 is vertically fixed on the top of the frame 3, and the telescopic end of the press-down hydraulic cylinder 1 is downward. Preferably, the press-down hydraulic cylinder 1 is fixed on the frame 3 by screws, and the hydraulic system A controls the press-down hydraulic pressure. The expansion and contraction of the cylinder 1, the frame 3 is also equipped with a photoelectric switch A, the photoelectric switch A is used to generate induction after the hydraulic cylinder 1 is extended to the preset position, and controls the hydraulic cylinder 1 to stop working, the photoelectric switch A The position of the push-pull is adjusted according to actual needs to disassemble or install the roll 5; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com