Manufacturing method of miniature steel balls

A manufacturing method and technology of miniature steel balls, which are applied to engine components, mechanical equipment, etc., can solve the problems of loose fiber structure, many worn-off parts, and large machining allowance, so as to achieve compact fiber structure, less loss of raw materials, and better processing. Small margin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

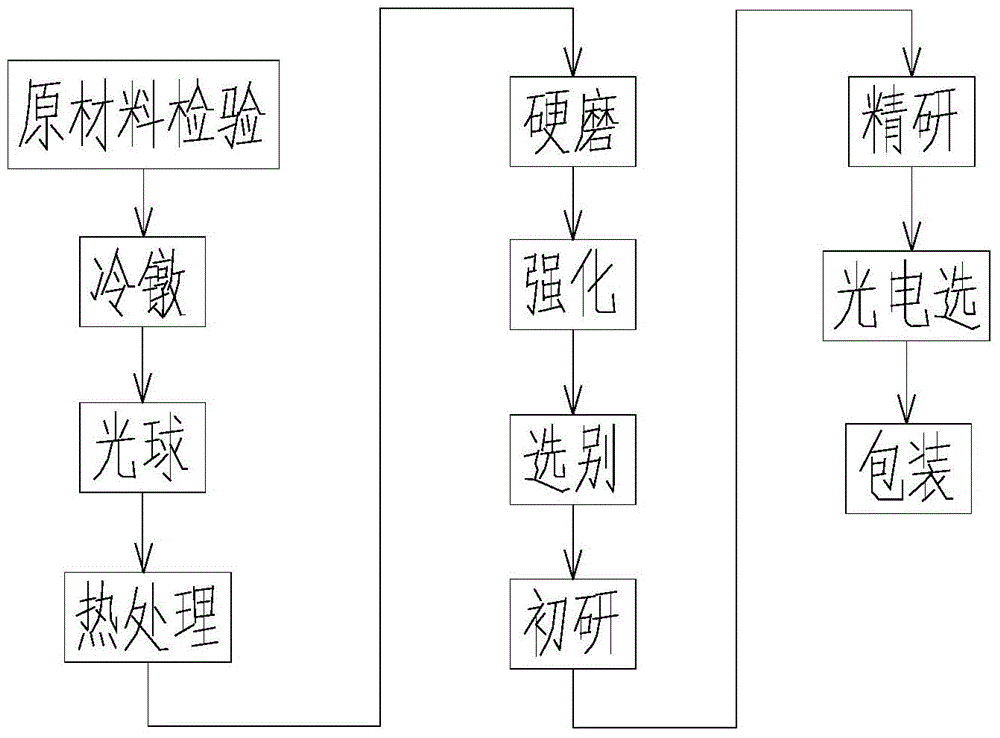

[0008] Micro-steel ball manufacture method of the present invention, as figure 1 As shown, it is composed of raw material inspection, cold heading, light ball, heat treatment, hard grinding, strengthening, sorting, preliminary research, fine research, photoelectric selection, and packaging steps carried out in sequence.

[0009] Cold heading adopts φ0.7㎜ small pole hole technology.

[0010] The diameter of the cold heading pole is 0.7mm or 0.8mm,

[0011] The cold heading allowance is 0.30mm, and the cold heading eccentricity difference is 0.04mm.

[0012] The diameter of cold heading cutting material is 1.4mm or 1.7mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com