A kind of centrifugal vaccine production method

A vaccine production, centrifugal technology, applied in centrifuges and other directions, can solve problems such as many limitations, damage to vaccines, and damage to vaccine structure, and achieve the effects of stable production sequence, increased survival rate, and improved survival efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

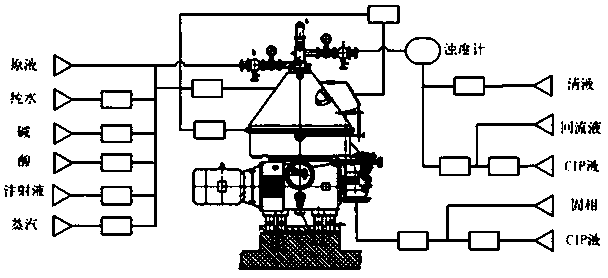

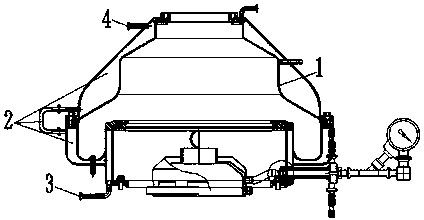

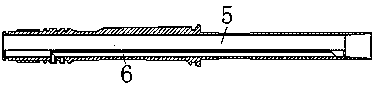

[0024] Such as figure 1 , figure 2 and image 3 As shown, the present invention is divided into several stages of pre-rinsing, intermediate rinsing, post-rinsing, disinfection, vaccine separation and post-treatment, wherein the pre-rinsing, intermediate rinsing and post-rinsing are carried out respectively before and after the disinfection and vaccine separation stages; Each of the stages operates in an orderly manner on liquids with different components, such as stock solution and pure water.

[0025] First, open the pure water inlet valve to realize the pre-cleaning of the whole machine, and replace the remaining materials with hot water with a flow rate of 5m³ / h. The flushing time is 2-5min, and wait until the temperature in the pipe and cavity of the whole machine reaches 70 At -80°C, close the pure water valve, open the alkali valve channel, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com