Groove wheel turnover device with auxiliary positioning function

A flipping device and auxiliary positioning technology, which is applied in the direction of feeding device, grinding device, grinding drive device, etc., can solve the problems of insufficient positioning accuracy and affect positioning reliability, and achieve the effect of reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

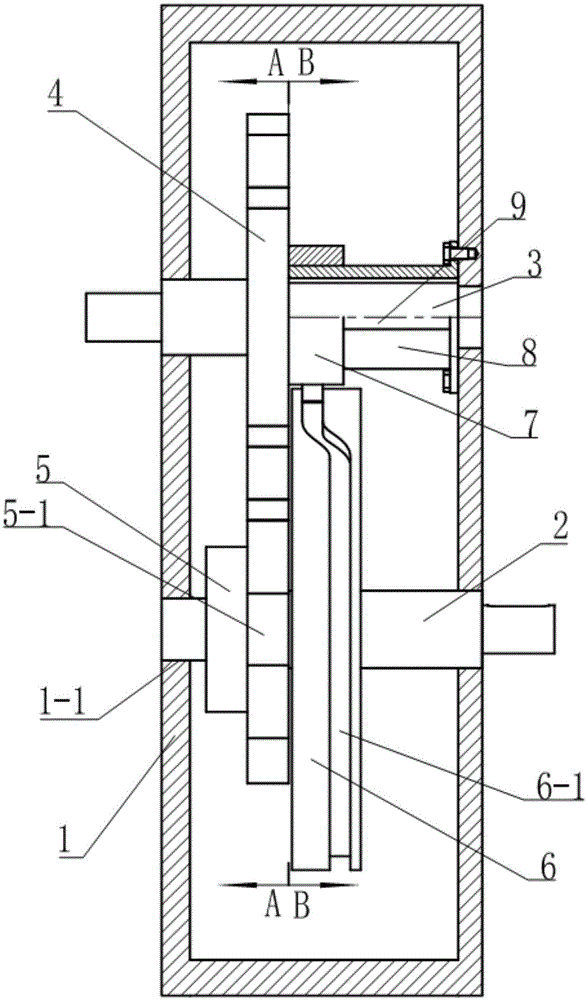

[0026] See Figure 1~4 , The sheave turning device in this example includes a box body 1, a transmission mechanism that drives the workpiece to turn, and an auxiliary positioning mechanism;

[0027] The box body 1 is provided with a support seat 1-1 for supporting the first transmission shaft 2 and the second transmission shaft 3, and the axes of the first transmission shaft 2 and the second transmission shaft 3 are parallel;

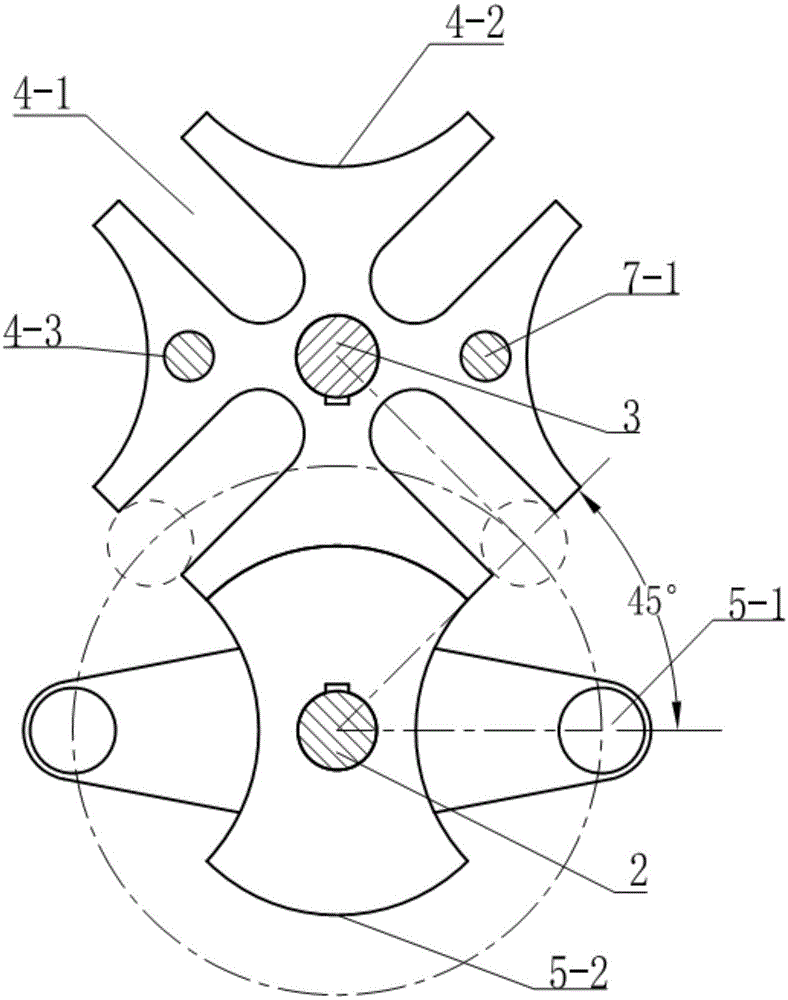

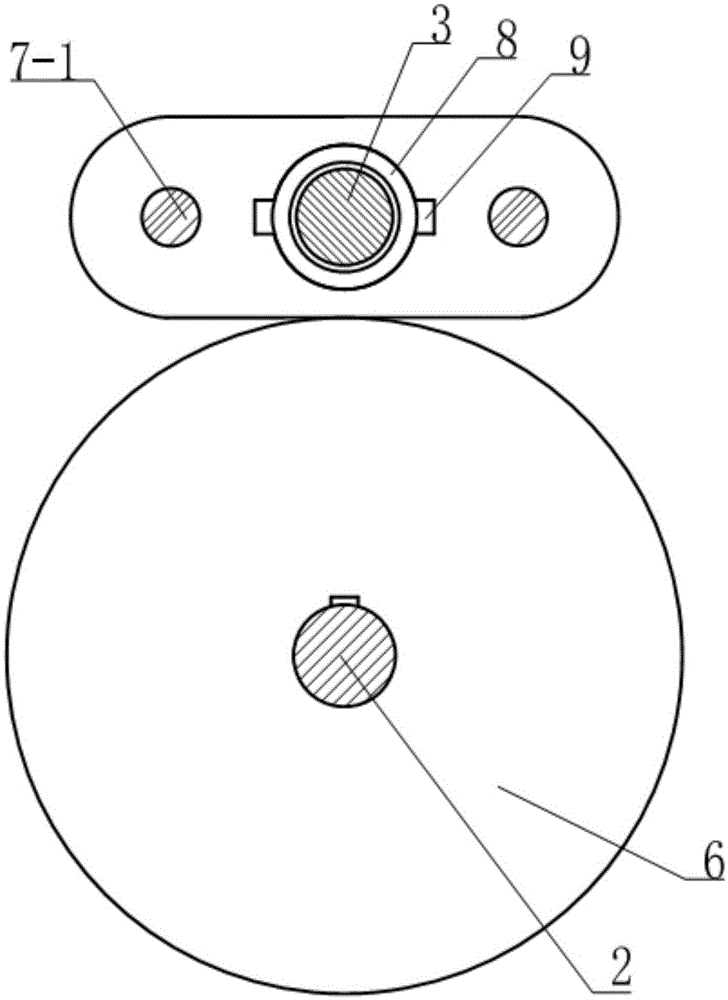

[0028] The transmission mechanism is an externally engaged sheave mechanism (see figure 2 ), the sheave mechanism includes an outer sheave 4 fixed on the second transmission shaft 3 and coaxial with the second transmission shaft 3 and a dial 5 fixed on the first transmission shaft 2 and coaxial with the first transmission shaft 2, The sheave has four dial grooves 4-1 evenly distributed around its axis, a concave locking arc 4-2 is arranged between any two dial grooves 4-1, and the end surface of the outer sheave 4 is provided with Two positioning holes 4-3;...

example 2

[0034] See Figure 9-11 , The dial has a section of convex locking arc 5-2 and two shift pins 5-1, the two shift pins 5-1 are rolling bearings whose inner ring is fixed on the dial 5, and the two shift pins 5 The angle between -1 and the center of rotation of dial 5 is 90 degrees;

[0035] See Picture 12 , The roller 7-3 moves in the curved groove 6-1, and the trajectory traced by its center is the theoretical profile c of the cylindrical cam 6, which is completely from the positioning pin 7-1. When the positioning hole 4-3 is inserted, the center position of the roller 7-3 is expanded, and the positioning pin 7-1 exits the process transition section of the positioning hole 4-3 (abscissa 0°~90°), and the end surface of the cylindrical cam 6 The parallel working section (abscissa 90°~270°) and the return transition section (abscissa 270°~360°) where the positioning pin 7-1 enters the positioning hole 4-3; the starting point of the process transition section to the The working d...

example 3

[0039] This example is a grinding machine whose worktable can be turned upside down by using the sheave wheel turning device of the present invention.

[0040] See Figure 13 with 14 The grinding machine in this example uses the Venturi jet 10 to suck and spray the grinding liquid mixed with steel balls stored in the mixing tank 12 to the surface of the workpiece, and then grind the surface of the workpiece. In order to prevent the grinding fluid from accumulating in the upward concave surface of the workpiece and hindering further processing, the grinding machine in this example has a turning table which includes a sheave turning device with auxiliary positioning as shown in Example 1. The box body 1 of the sheave turning device is fixed on the side of the frame 14 of the grinder, and one end of the second drive shaft 3 extends directly above the recovery funnel 15 located inside the frame 14, which extends to the inside of the frame 14. A T-slot worktable 11 is provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com