A surface strengthening grinding machine with a worktable that can be turned up and down

A surface strengthening and workbench technology, which is applied in the direction of grinding machine tools, grinding devices, manufacturing tools, etc., can solve the problems of affecting the processing accuracy of the grinding machine, affecting the positioning reliability, and insufficient positioning accuracy, so as to achieve the effect of reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

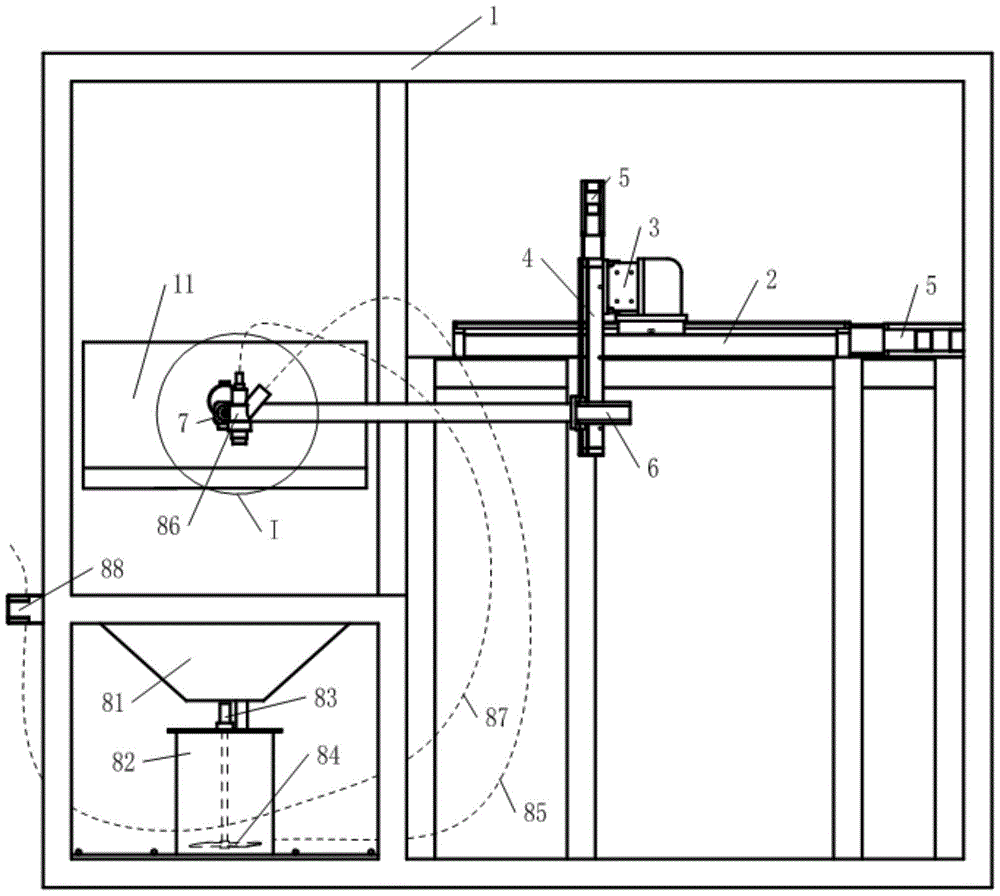

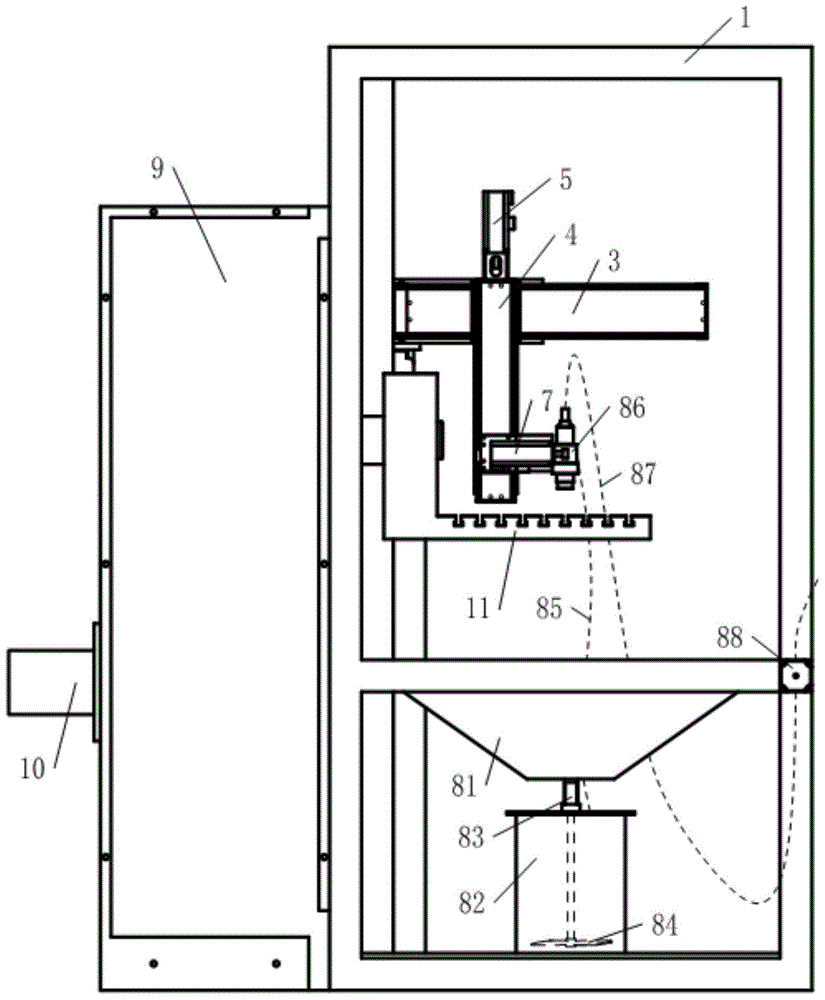

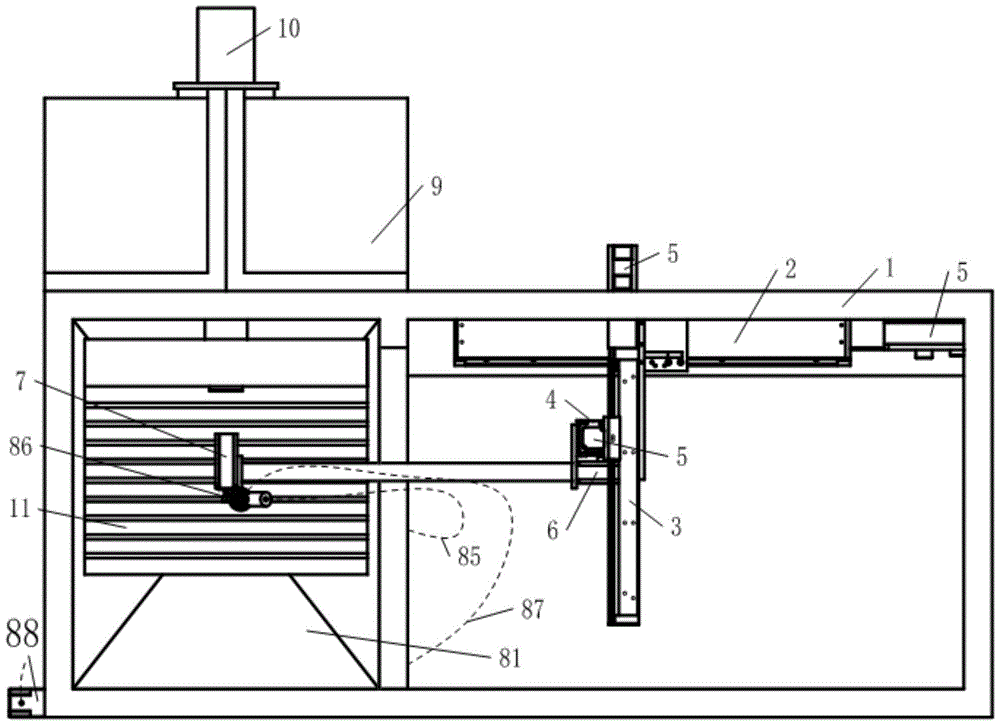

[0033] see Figure 1~3 and 5, the rear side of the frame 1 in this example is provided with a fixed frame for fixing the screw drive system, and the left part is provided with a funnel platform for fixing the grinding liquid recovery funnel 81, and the screw drive system is fixed on the X-axis ball screw pair 2 on the fixed frame, Y-axis ball screw pair 3 fixed on the slider of X-axis ball screw pair 2, and Z-axis fixed on the slider of Y-axis ball screw pair 3 Ball screw pairs 4 are formed; the moving directions of the three groups of ball screw pairs are perpendicular to each other, and a servo motor 5 is connected to the lead screw of each group of screw pairs. The slider of the Z-axis ball screw pair 4 is provided with a first corner motor 6 whose rotating shaft is parallel to the moving direction of the X-axis ball screw pair 2, and the rotating shaft of the first corner motor 6 passes through a The long rod is suspended with a second angle motor 7 whose rotating shaft i...

example 2

[0045] The difference between this example and Example 1 is that the structures of the mechanisms inside the drive box are different.

[0046] see Figure 16 and 17 , the dial has a convex locking arc 952 and two dial pins 951, the two dial pins 951 are rolling bearings whose inner rings are fixed on the dial 95, and the two dial pins 951 and the rotation center of the dial 95 The angle between the connecting lines is 90 degrees;

[0047] see Figure 18 , the roller 973 moves in the curved groove 961, and the track traced by its center is the theoretical profile c of the cylindrical cam 96, when the theoretical profile c is completely inserted into the positioning hole 943 from the positioning pin 971 The center position of the roller 973 is unfolded, the process transition section (abscissa 0°-90°) exiting the locating hole 943 from the locating pin 971, and the working section parallel to the end face of the cylindrical cam 96 (abscissa 90°-270°) It is composed of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com