Position sensing mechanism

A coding element and magnetoresistive technology, applied in the field of position sensing mechanism, can solve problems such as low sensitivity, Hall sensing elements are difficult to meet the needs of the industry, and the degree of accuracy affects the accuracy of position discrimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

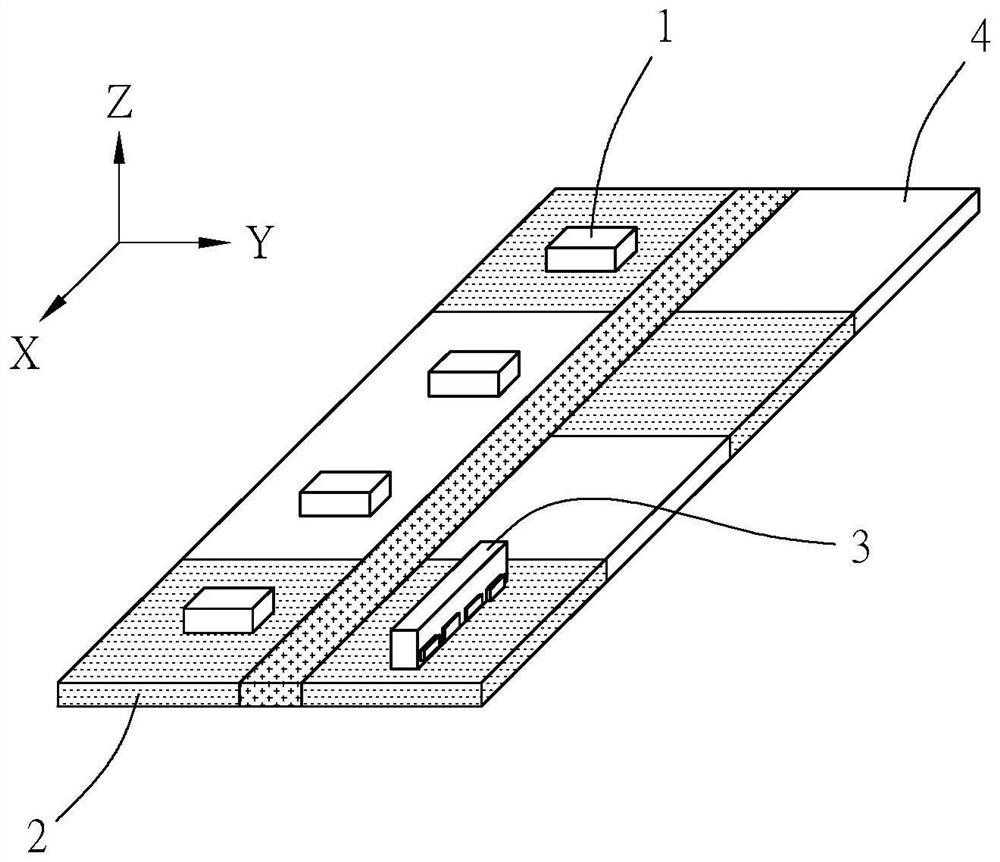

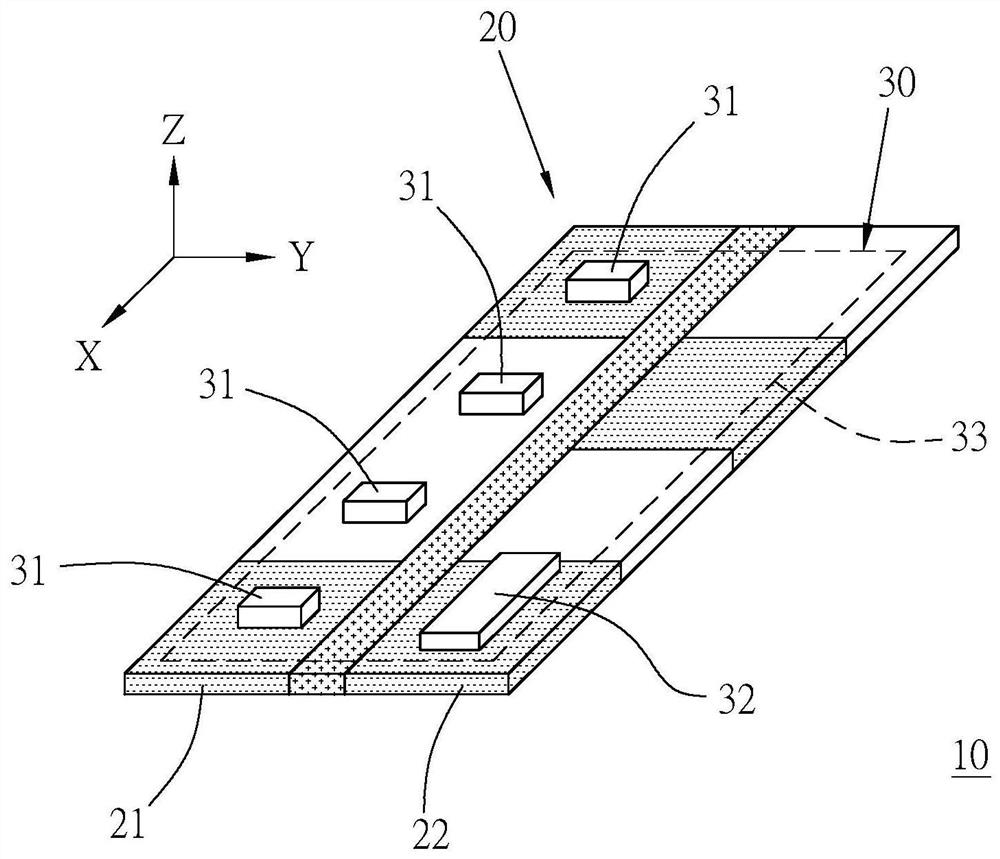

[0028] First, see figure 2 As shown, the position sensing mechanism 10 provided in a preferred embodiment of the present invention mainly includes an encoding element 20, a reading element 30 and a processing unit (not shown in the figure).

[0029] The encoding element 20 is based on the existing magnetic scale technology with a magnetic field as a signal source. The column tracks 22 extend parallel to each other along a virtual axis of movement, and as figure 2 The shown x-y plane changes the magnetic poles according to the preset coding method. Generally speaking, the moving axis is usually linear and is consistent with the length direction of the magnetic ruler. Since the magnetic scale technology related to the incremental row magnetic track 22 belongs to the prior art content known to those skilled in the art to which the present invention pertains before the application of the present invention, its specific magnetic pole arrangement, manufacturing process or related...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com