Mining locomotive walking part system

A technology of running gear and locomotives, applied in the field of running gear systems of electric locomotives, can solve problems such as inability to adapt to terrain, complex structure of mining locomotives, and fragile locomotive parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

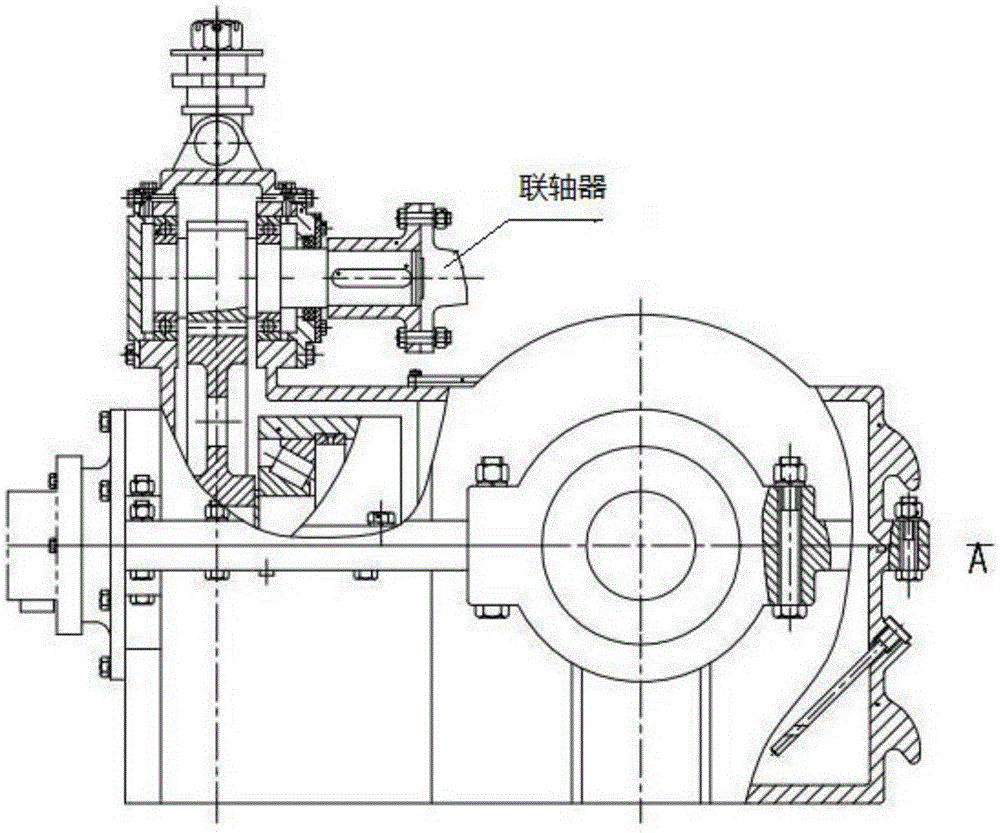

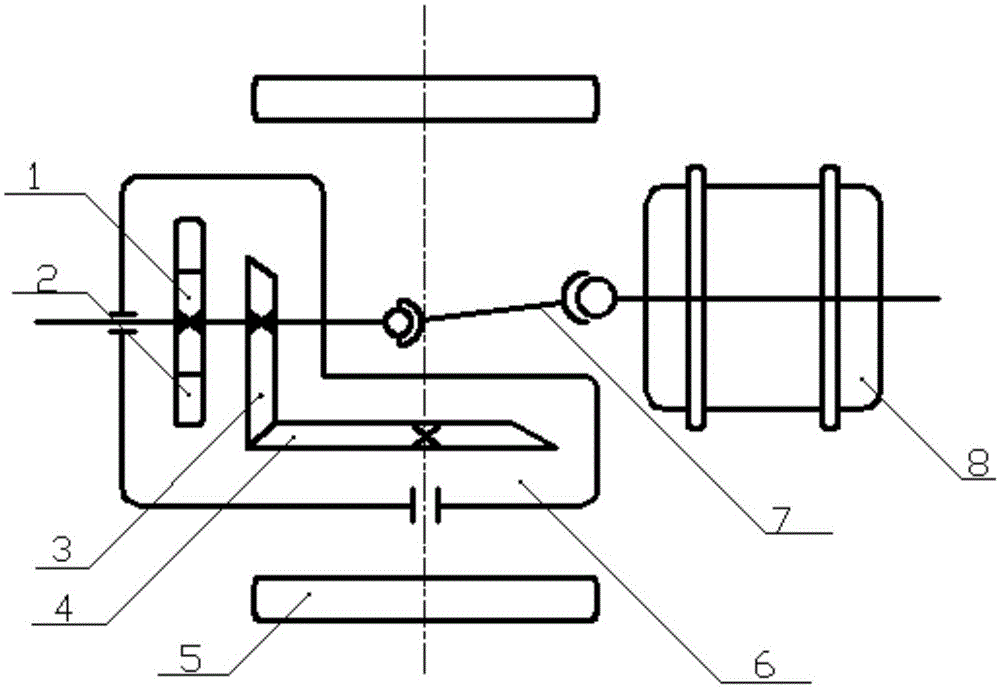

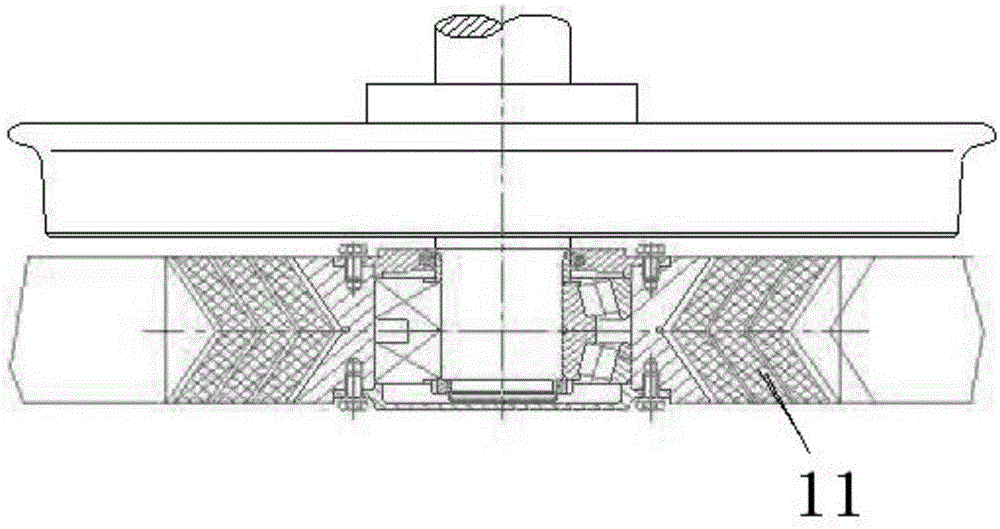

[0023] In the figure, the running part system of the mining locomotive includes an electric motor 8, and the running part of the running part system of the mining locomotive is a two-wheel pair running part without a bogie. The profile reducer 6, the braking device, the car body 9 and the two wheels are connected through a traction damping device, wherein the motor 8 is connected to the profile reducer through a power transmission device, and the power transmission device is preferably a universal joint 7, At the same time, the wheel set is also connected with the profile reducer. The motor 8 drives the profile reducer to drive the wheel set to move. The connection of the device can adopt the existing technology, which will not be described in detail here, and the electric motor in the present invention adopts an AC traction motor.

[0024] Since the running part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com