Organic phase change thermal storage material and preparation method thereof

A heat storage material and organic phase technology, which is applied in the field of composite materials, can solve the problems of poor thermal conductivity of organic phase change heat storage materials, and achieve the effect of improving the cold and heat storage function, not easy to burn, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

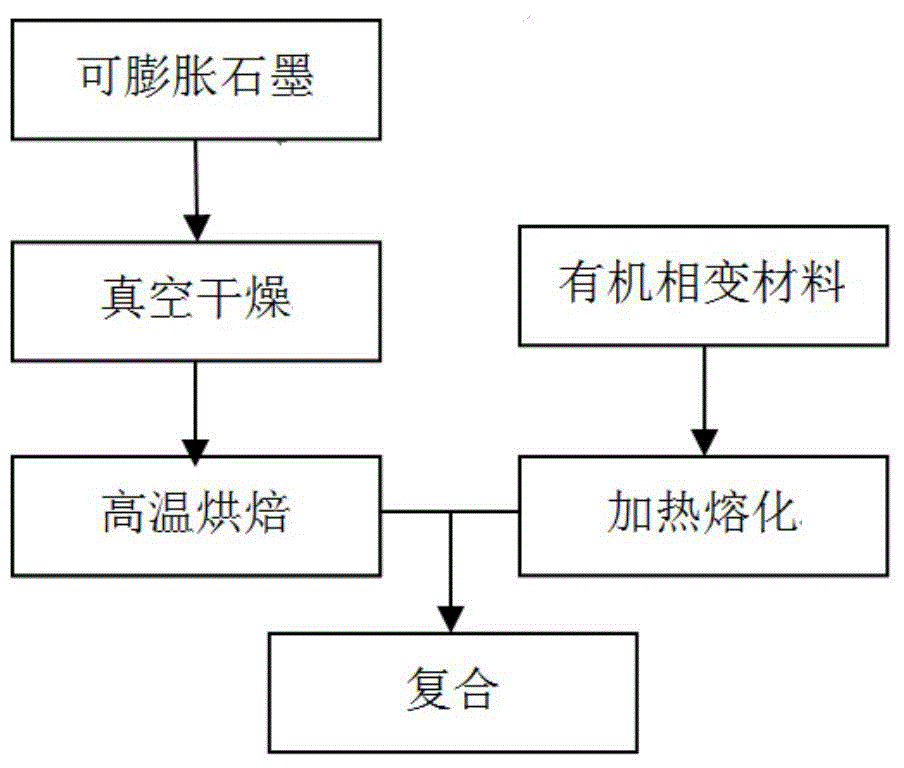

[0032] Such as figure 1 As shown, the preparation process of organic phase change heat storage materials is as follows:

[0033] Take 50g of expandable graphite (the expansion rate is 150ml / g, the particle size is 70 mesh), place it in a vacuum drying oven with a vacuum degree of 0.1pa, and the vacuum drying time is 24 hours, then put it into a 100ml stainless steel container, and finally place Baked at 600°C for 3 hours in a muffle furnace.

[0034] Take 950g of polyethylene organic phase change material, place it in a 3000ml container, place the container on an electric heating platform with a heating power of 1KW, and place a temperature measuring element in the container to monitor the heating process. Temperature profile of organic phase change materials. When the temperature is 20°C higher than the melting point, reduce the heating power appropriately to slow down the rate of temperature rise. When the temperature is 50°C higher than the melting point, keep the tempera...

Embodiment 2

[0037] Such as figure 1 As shown, the preparation process of organic phase change energy storage materials is as follows:

[0038] Take 100g of expandable graphite (the expansion rate is 200ml / g, the particle size is 60 mesh), put it in a vacuum drying oven, the vacuum degree is 0.1pa, and the vacuum drying time is 32 hours, then put it into a 100ml stainless steel container, and finally place it Baked in a muffle furnace at 700°C for 3 hours.

[0039] Take 900g of stearic acid organic phase change material, place it in a 3000ml container, place the container on an electric heating platform with a heating power of 1KW, and place a temperature measuring element in the container to monitor the temperature during the heating process. , the temperature condition of the organic phase change material. When the temperature is 20°C higher than the melting point, reduce the heating power appropriately to slow down the rate of temperature rise. When the temperature is 50°C higher than...

Embodiment 3

[0042] Such as figure 1 As shown, the preparation process of organic phase change energy storage materials is as follows:

[0043] Take 40g of expandable graphite (the expansion rate is 250ml / g, the particle size is 40 mesh), place it in a vacuum drying oven, the vacuum degree is 0.1pa, and the vacuum drying time is 18 hours, then put it into a 100ml stainless steel container, and finally place Calcined at 650°C for 4 hours in a muffle furnace.

[0044] Take 960g of n-eicosane organic phase change material, place it in a 3000ml container, place the container on an electric heating platform with a heating power of 1KW, and place a temperature measuring element in the container to monitor the heating process , the temperature conditions of organic phase change materials. When the temperature is 20°C higher than the melting point, reduce the heating power appropriately to slow down the rate of temperature rise. When the temperature is 50°C higher than the melting point, keep th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com