Rapid heating or cooling device for solid pellets

A cooling device and pellet technology, applied in the direction of roads, road repairs, roads, etc., can solve the problems of uneven heating and can not meet production needs, achieve uniform heating/cooling, improve heating/cooling efficiency, and reduce accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

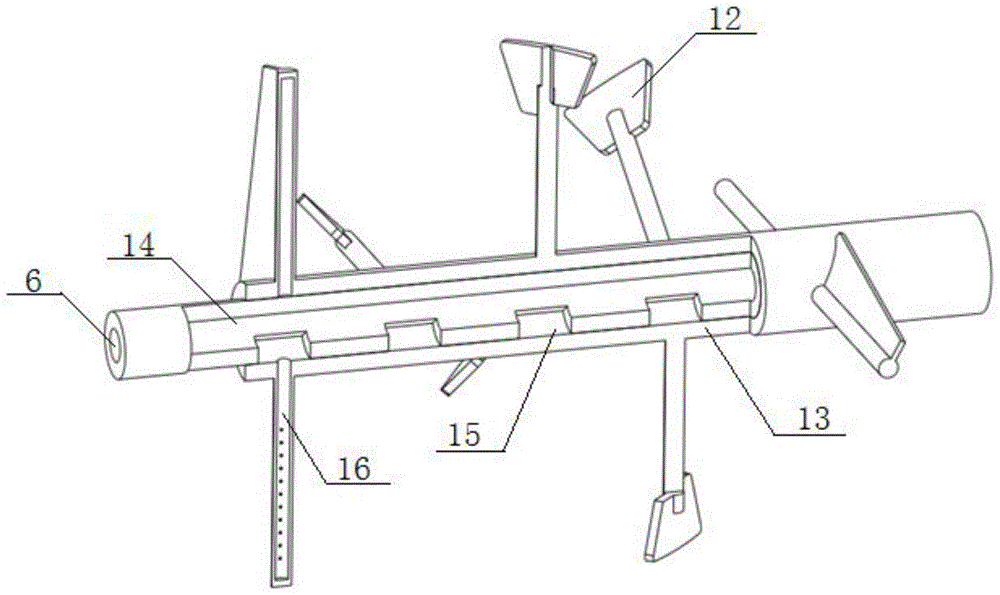

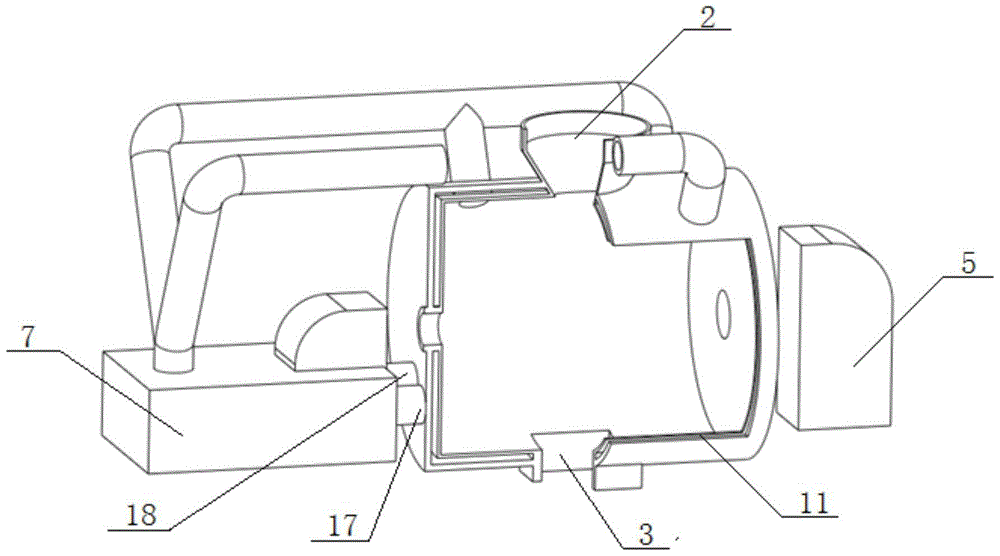

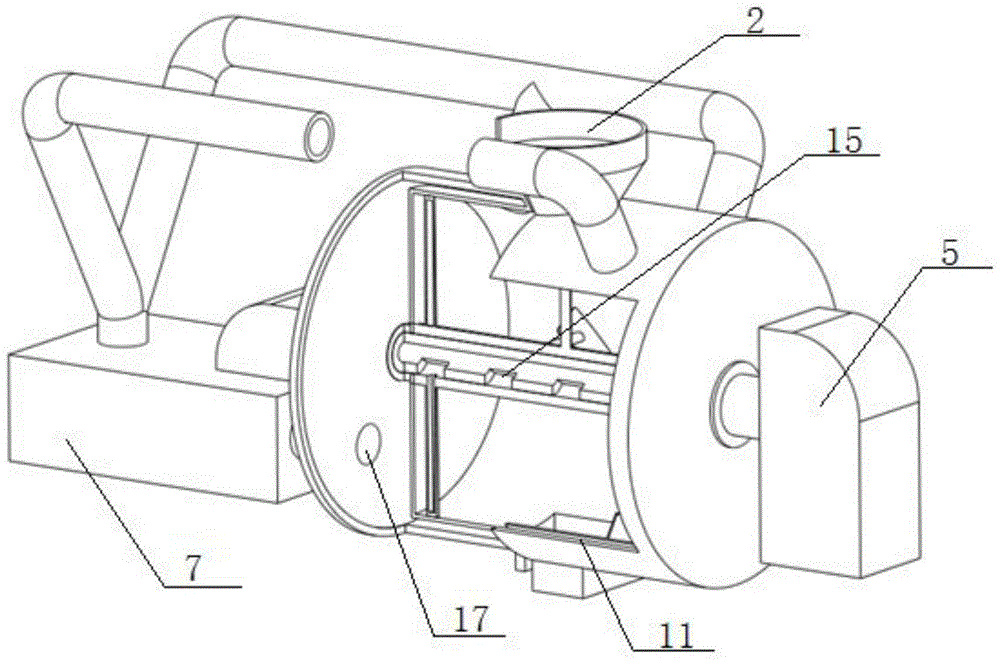

[0025] Such as Figure 1~6 The schematic diagram of the rapid heating or cooling device for solid pellets of the present invention includes a liquid circulation system 7, a gas circulation system and a stirring device,

[0026] The liquid circulation system 7 includes a circulation oil inlet 17, a circulation oil outlet 18 and a stirring tank shell 11; the gas circulation system includes a circulation gas recovery port, a circulation air inlet 6, a heat exchange pipe 8, an air filling port 9, Gas outlet 10, gas circulation shaft 14, gas distribution valve port 15 and gas delivery channel 16; the stirring device includes a stirring tank 1, a stirring motor 5, blade screw shaft 13 and blade 12, and also includes a feeding port 2 and a discharging port 3.

[0027] The interior of the liquid circulation system 7 mainly includes heaters, circulation channels, pressurizers, temperature control components and other parts, and the exterior of the liquid circulation system 7 is respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com