Template system for building concrete structure at earth-taking opening in top-down construction method, and construction method

A concrete structure and soil intake technology, which is applied in the direction of basic structure engineering, formwork/formwork/work frame, underwater structures, etc., can solve the problems of shortening the construction period, delaying the progress of the project, and taking up a lot of time Effects of construction period, project cost reduction and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

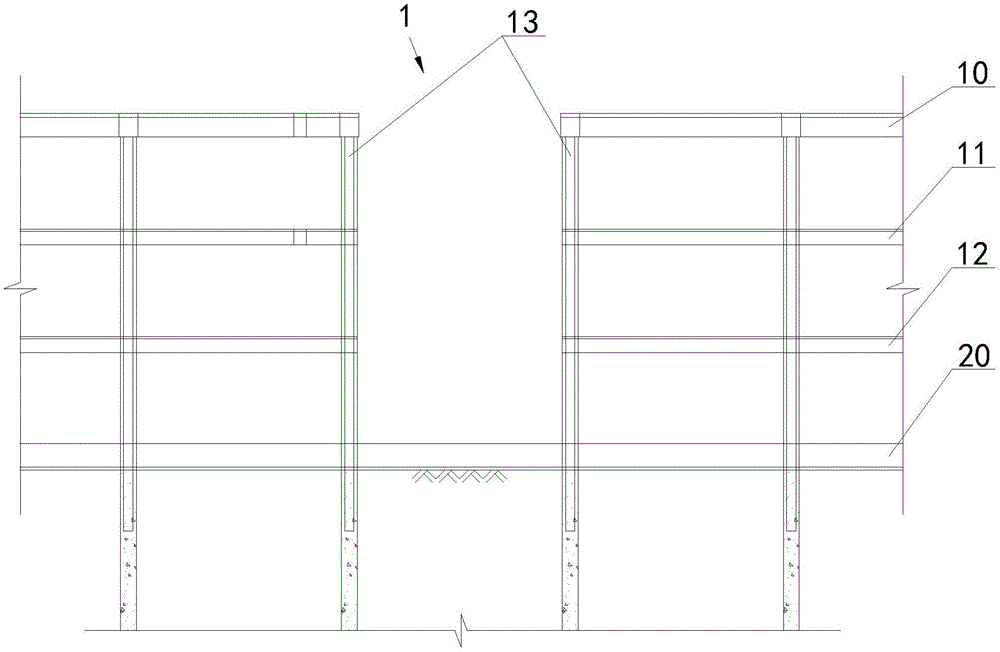

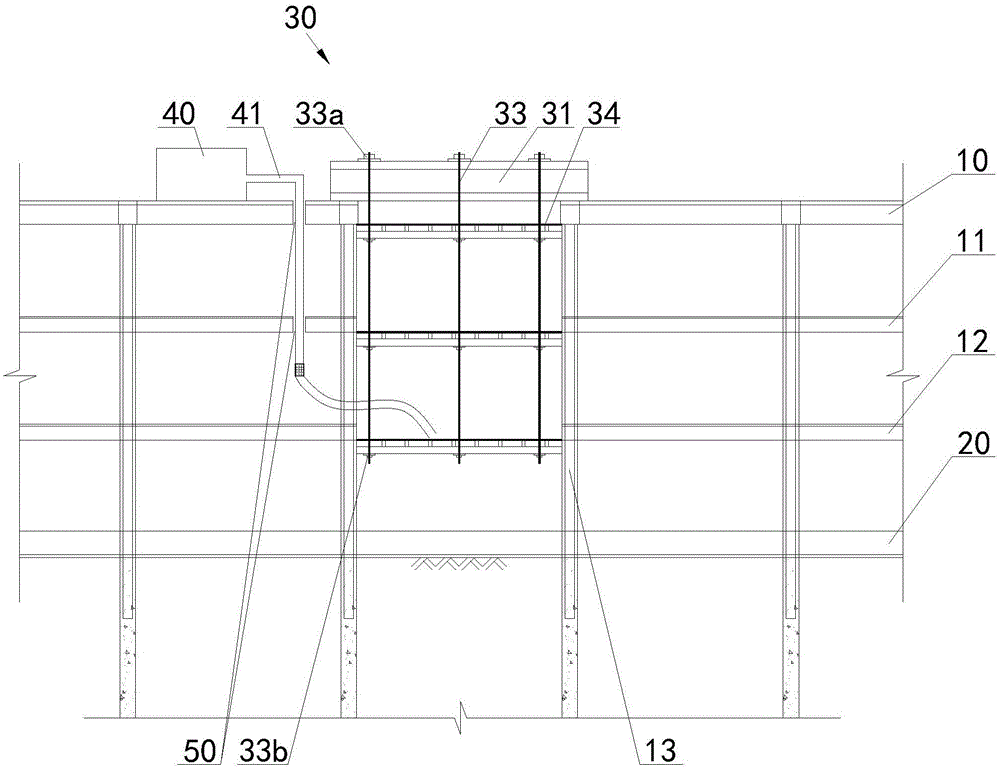

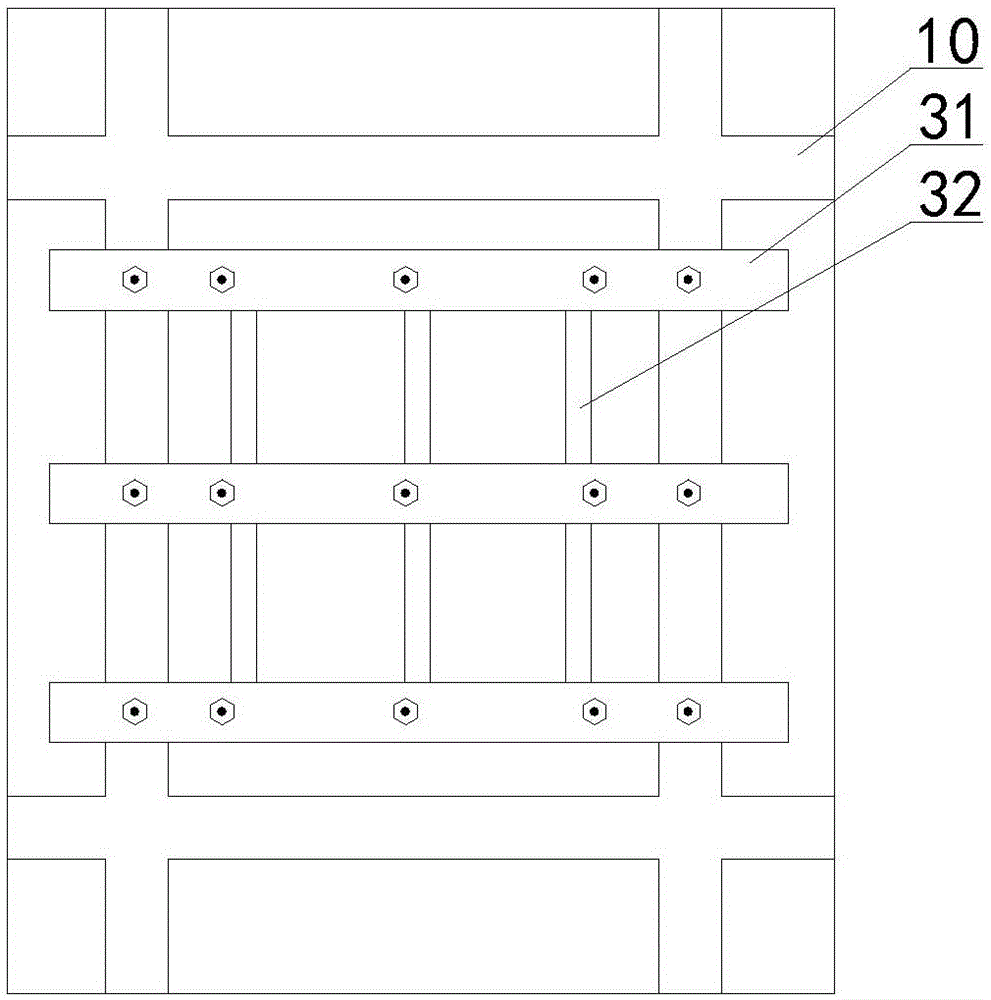

[0027] Embodiment one: if figure 1 As shown, this embodiment takes the supplementary construction of a floor slab at the soil intake of an underground project as an example. It should be pointed out that at this time, the main structure of the three underground floors is basically completed, and the figure shows the roof 10, As for the base plate 20, the floor slab 11 of the first basement, the floor 12 of the second basement and the structural column 13, only one soil-borrowing point has not yet been rebuilt. Combine below Figure 2 to Figure 6 Describe the formwork system 30 for constructing a concrete structure at the soil intake in the upside-down method of this embodiment, which includes three hanging steel beams 31 arranged parallel to the roof 10 and erected on both sides of the soil intake 1, two adjacent hanging steel beams 31 The steel beams 31 are fixedly connected by three connecting beams 32 to form a stable frame structure; each hanging steel beam 31 is connecte...

Embodiment 2

[0035] Embodiment two: the present invention also provides a kind of construction method that utilizes formwork system 30 described in embodiment one to construct the concrete structure, below in conjunction with Figure 2 to Figure 6 Describe the specific steps of the construction method:

[0036] 1. Install the formwork system 30 at the soil intake 1 of the underground main body project, erect the hanging steel beam 31 on the top floor 10 of the underground main structure, and arrange three formwork components 34 arranged in the longitudinal direction in the soil intake 1 , and the two ends of the formwork assembly 34 are against the structural column 13, and the upper surface of the formwork assembly 34 is flush with the lower surface of the floor of the corresponding underground main structure;

[0037] 2. Bind the steel bars in the three formwork components 34 at the same time, so that the steel bars are fixed to the embedded steel bars in the corresponding floor slabs, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com