Vacuum freeze-drying technological method

A process method and vacuum freeze-drying technology, applied in the field of freeze-drying technology, can solve the problems that the original flavor of food cannot be guaranteed, and can not meet the requirements of instant food, etc., and achieve the effects of increasing diversity, increasing scope, and reducing the difficulty of drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

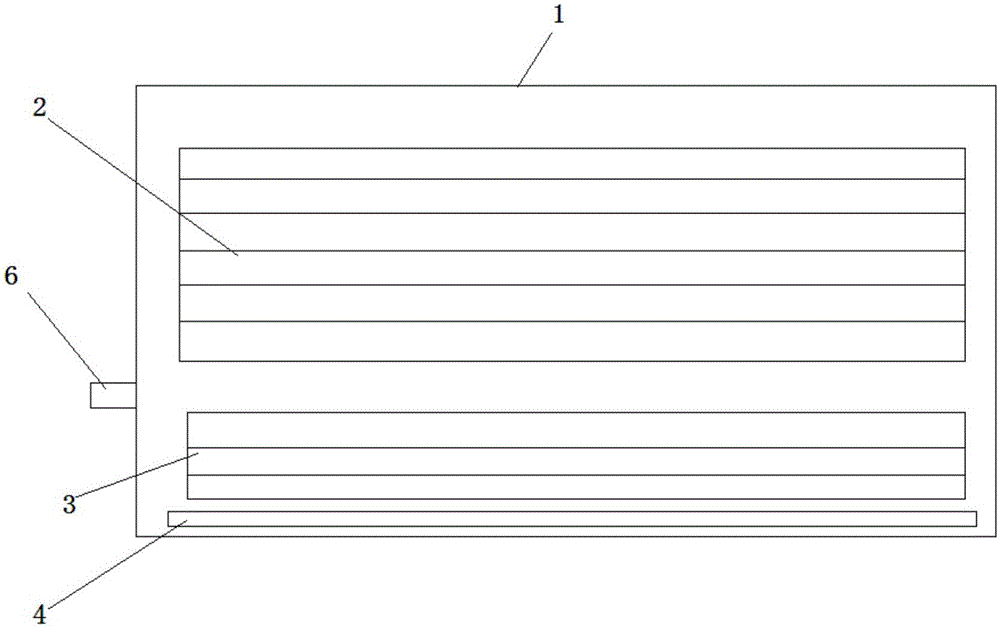

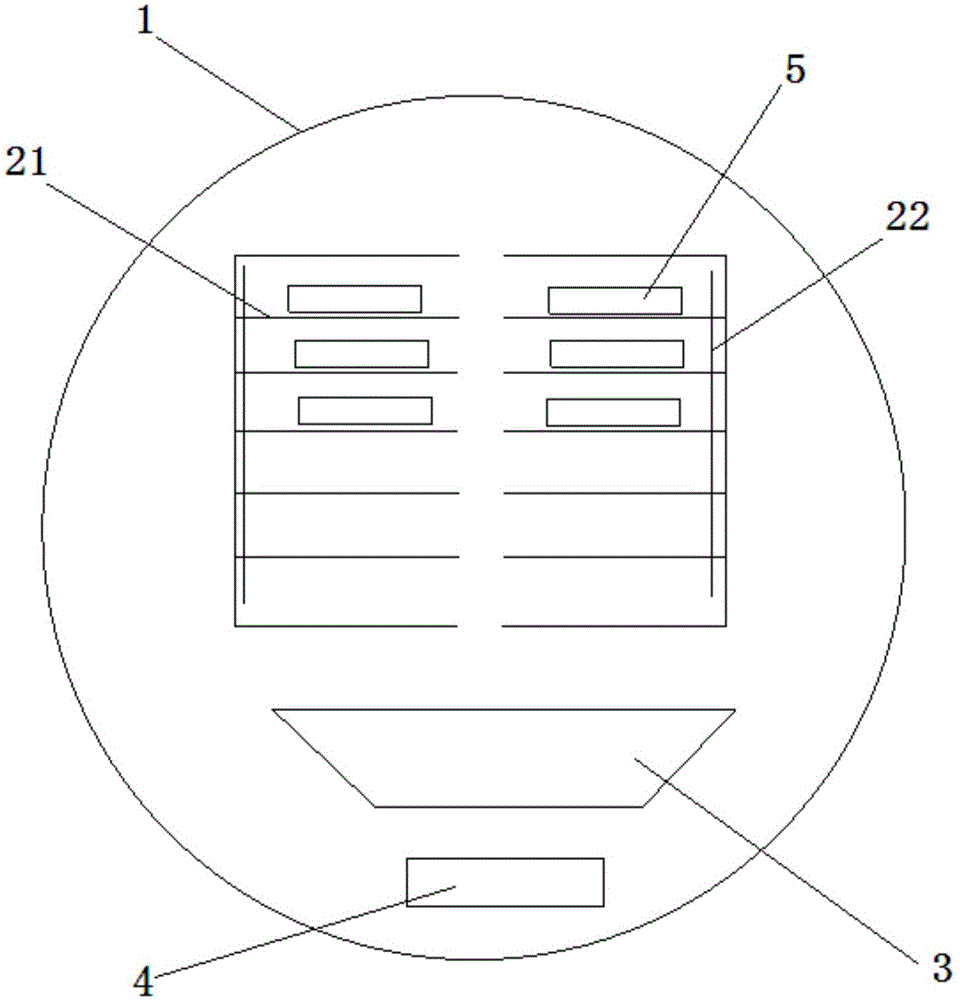

[0016] The dryer mainly includes: refrigeration system, heating system, vacuum system, and control system. During the entire material freeze-drying process, the moisture in the material is removed through the cooperation of the four major systems. The specific structure is as follows: figure 1 , figure 2 As shown, it includes a housing 1, the upper part of the housing 1 is provided with a heating box 2, the lower part of the heating box 2 is provided with a cold trap 3, and the lower side of the cold trap 3 is provided with a defrosting device 4; the heating box is set in half , the interior of the heating box is provided with a multi-layer heating grid 21, and the material box 5 is placed on the heating grid 21; the housing 1 is provided with a vacuum tube 6, and the vacuum tube 6 is connected to a vacuum pump.

[0017] The heating system includes: heating controller, cold water tank, hot water tank, circulation pump, connecting pipes, heating plate in the warehouse, tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com