Patents

Literature

50 results about "Snap freezing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Snap freezing (or cook-chill or blast freezing) is the process of rapid cooling of a substance for the purpose of preservation. It is widely used in the culinary and scientific industries.

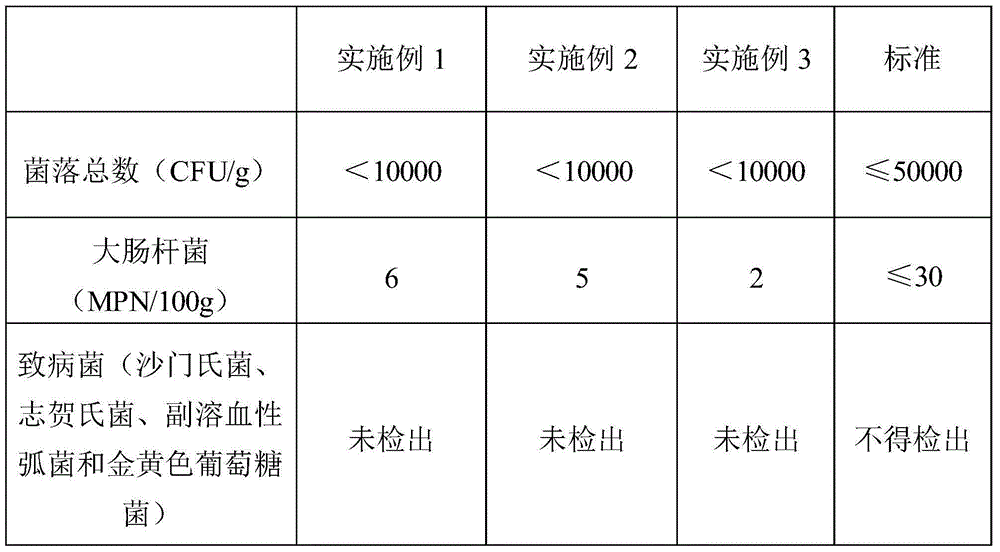

Method for making solanaceous vegetables pickled vegetable by using a multistage superhigh pressure broth penetration technology

The invention discloses a method for making solanaceous vegetables pickled vegetable by using a multistage superhigh pressure broth penetration technology. The method comprises the following steps: pretreating solanaceous vegetables, treating with air drying, quickly freezing in a quick-frozen tunnel and storing with refrigeration, preparing a broth having a pickled vegetable local flavor and using the multistage superhigh pressure penetration technology. According to the invention, original color, local flavor, nutrition and reconstitution property of the vegetables can be fully kept, salt content is reduced, generation of nitrite is reduced, realization of industrially continuous production of the Szechwan pickled vegetable in a whole year can be fully guaranteed, production efficiency of factory and equipment can be increased, compared with traditional nature fermentation, the production process in the invention is easy to control, and the product taste is pure.

Owner:XIHUA UNIV

Vacuum freeze drying production method of nuts and nut product

InactiveCN103141919ALong storage timeOrganizational structure unchangedFood preparationFood treatmentFlavorAdditive ingredient

The invention provides a vacuum freeze drying production method of nuts, which comprises the following steps of quickly freezing the nuts between -35 DEG C and -55 DEG C, and conducting vacuum drying on the quickly frozen nuts for 10-15h under a vacuum environment at the medium temperature of 55-35 DEG C and the vacuum degree of 35-115Pa. The invention further provides a nut product manufactured by applying the vacuum freeze drying production method of the nuts. According to the production method and the nut product, a vacuum freeze drying mode is adopted to produce the nut product, the saving time of the nuts is prolonged, organization structures, nutritional ingredients and flavor substances of the nuts are kept unchanged, the appearances of the nuts are free from sun cracks and are not shrunk, the original shapes and colors of the nuts are maintained, and the taste is crisp and nice.

Owner:ANHUI ZHANSHI FOOD

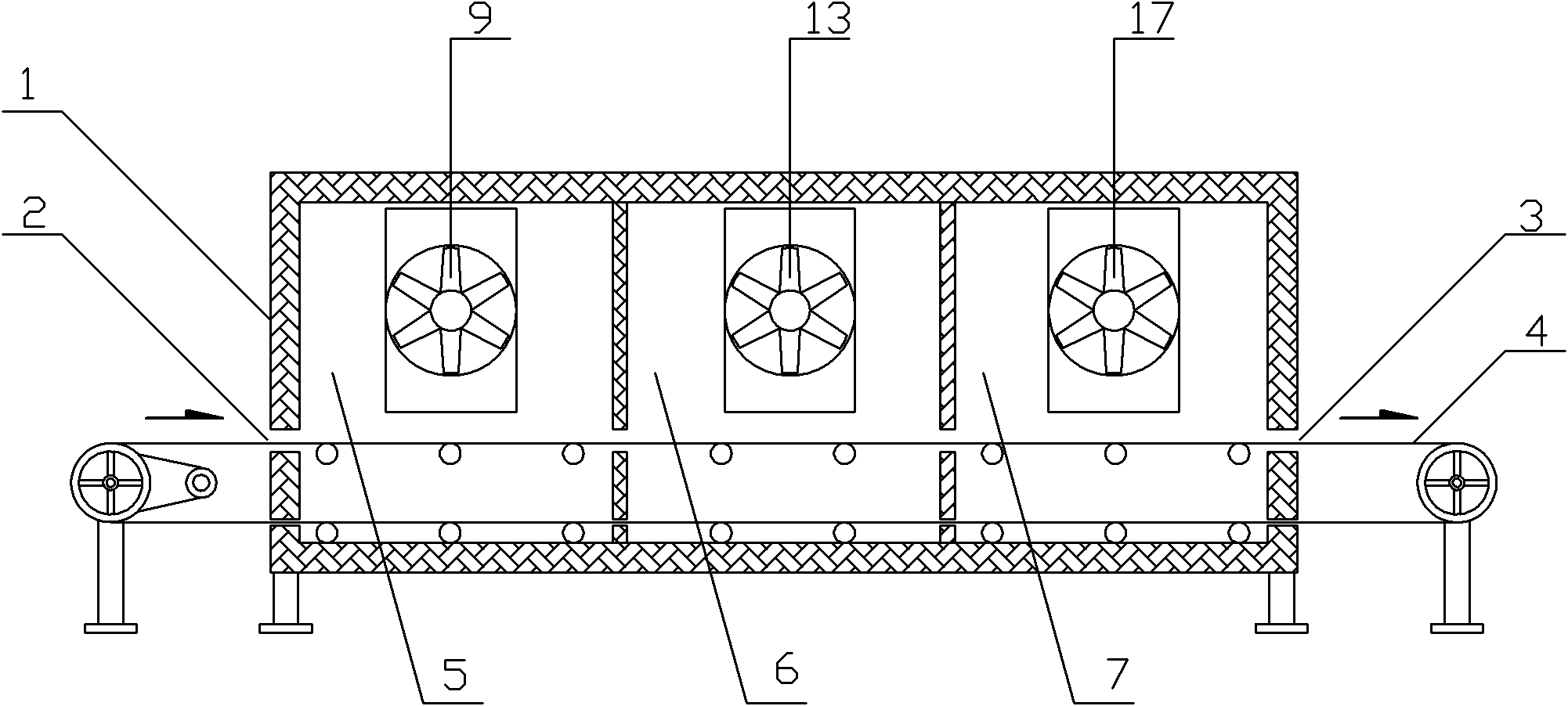

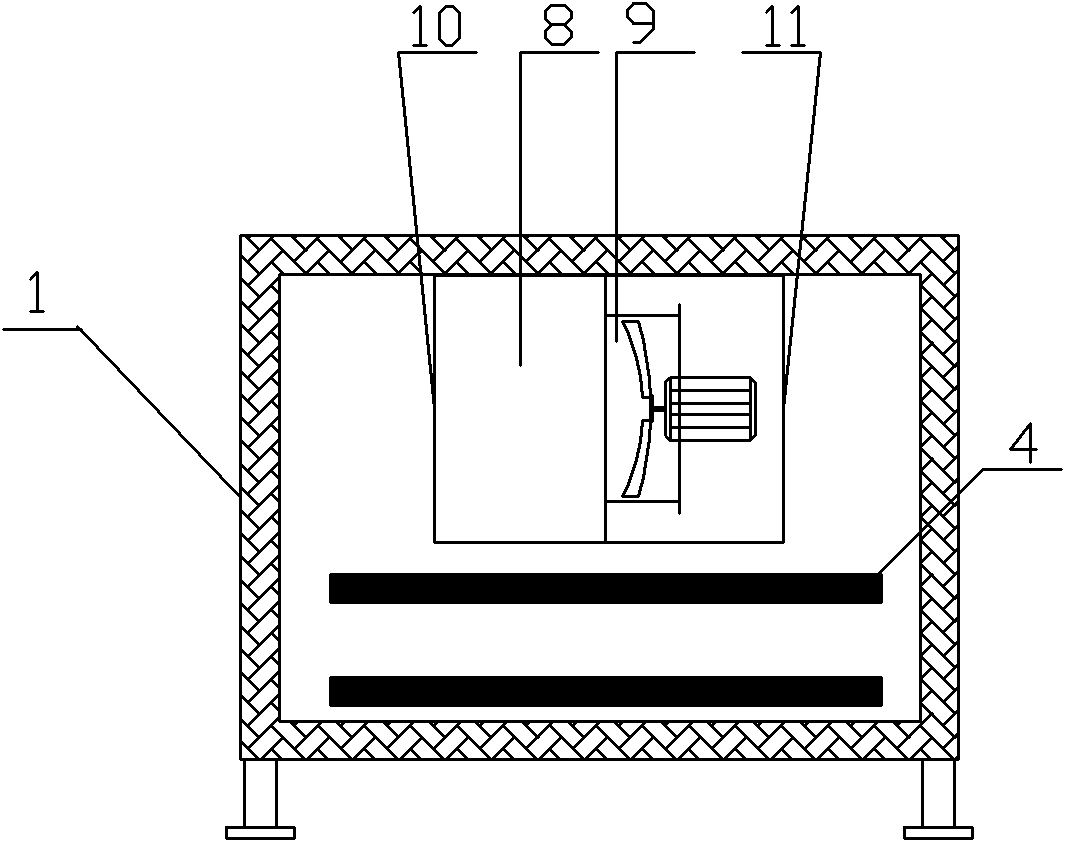

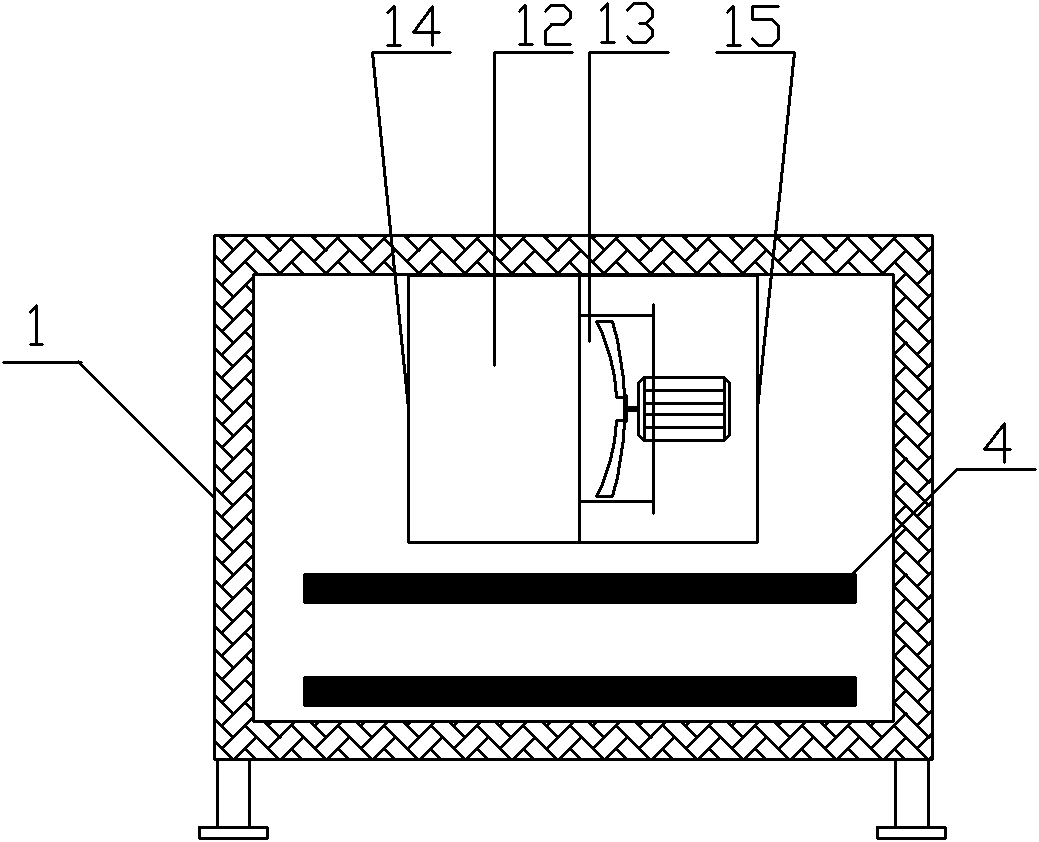

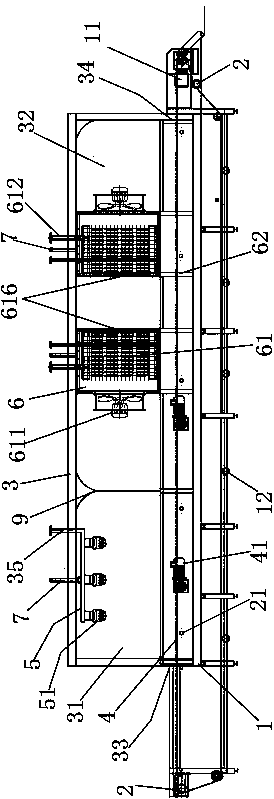

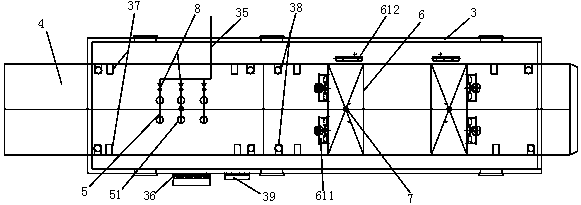

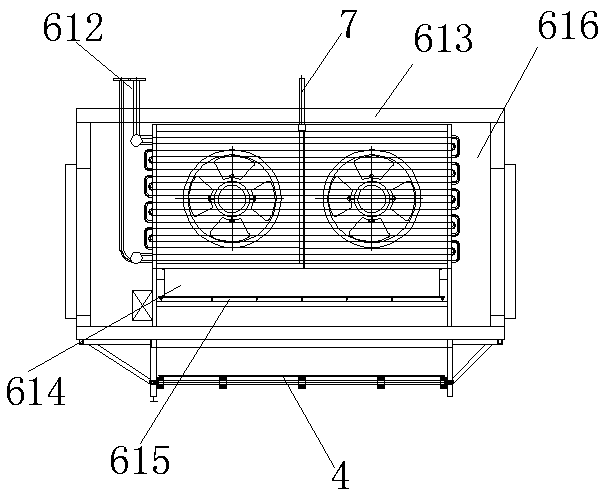

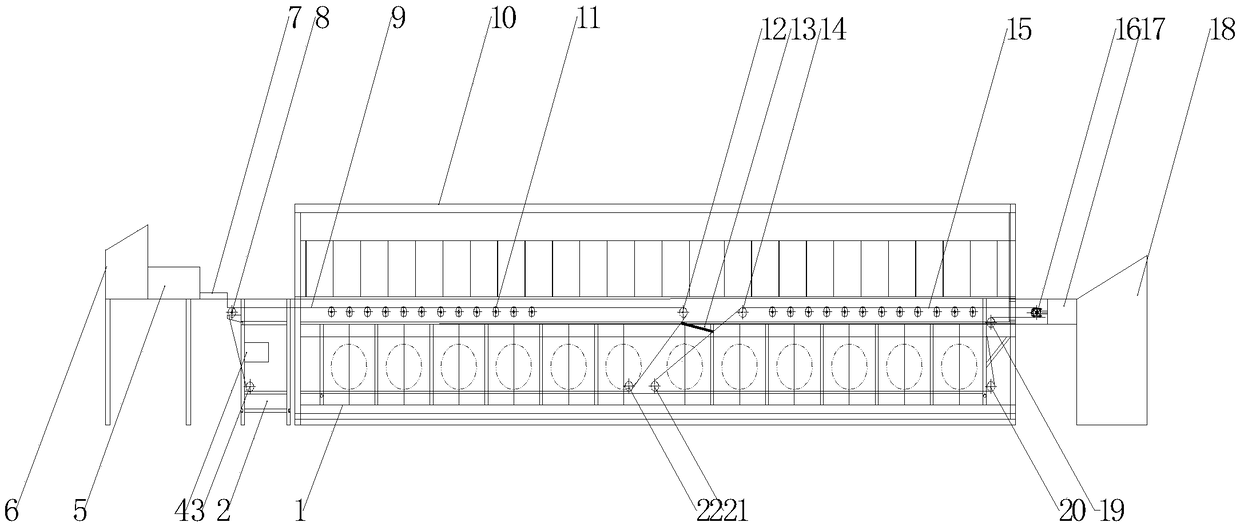

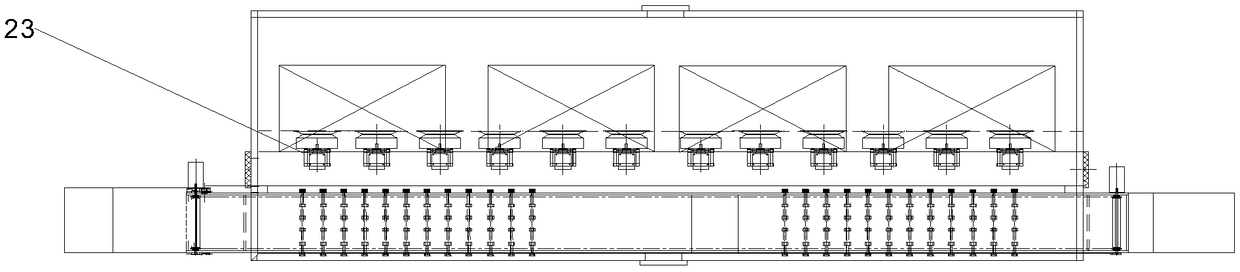

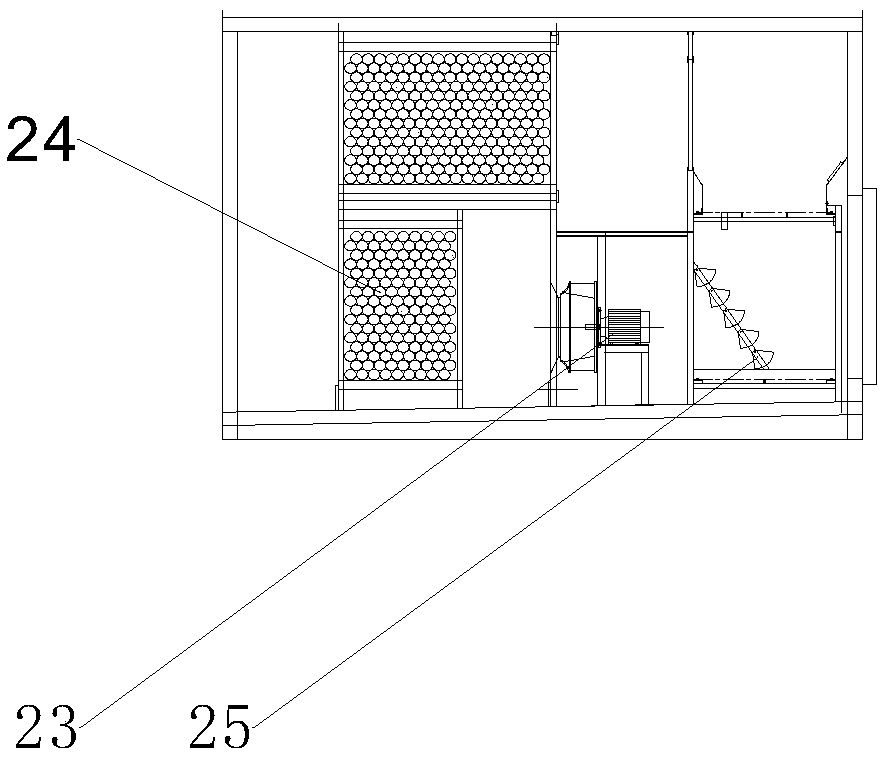

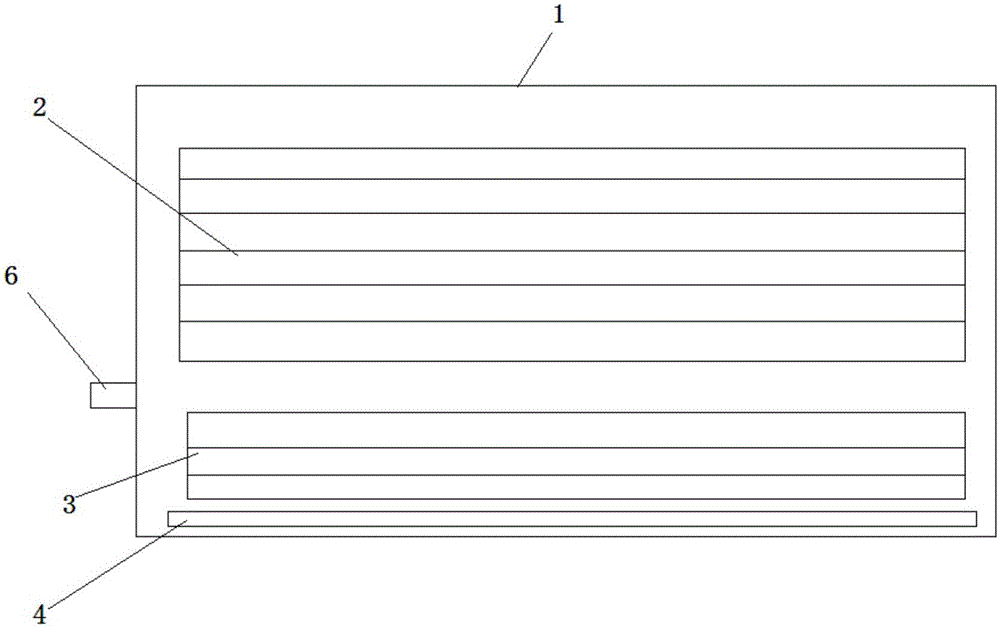

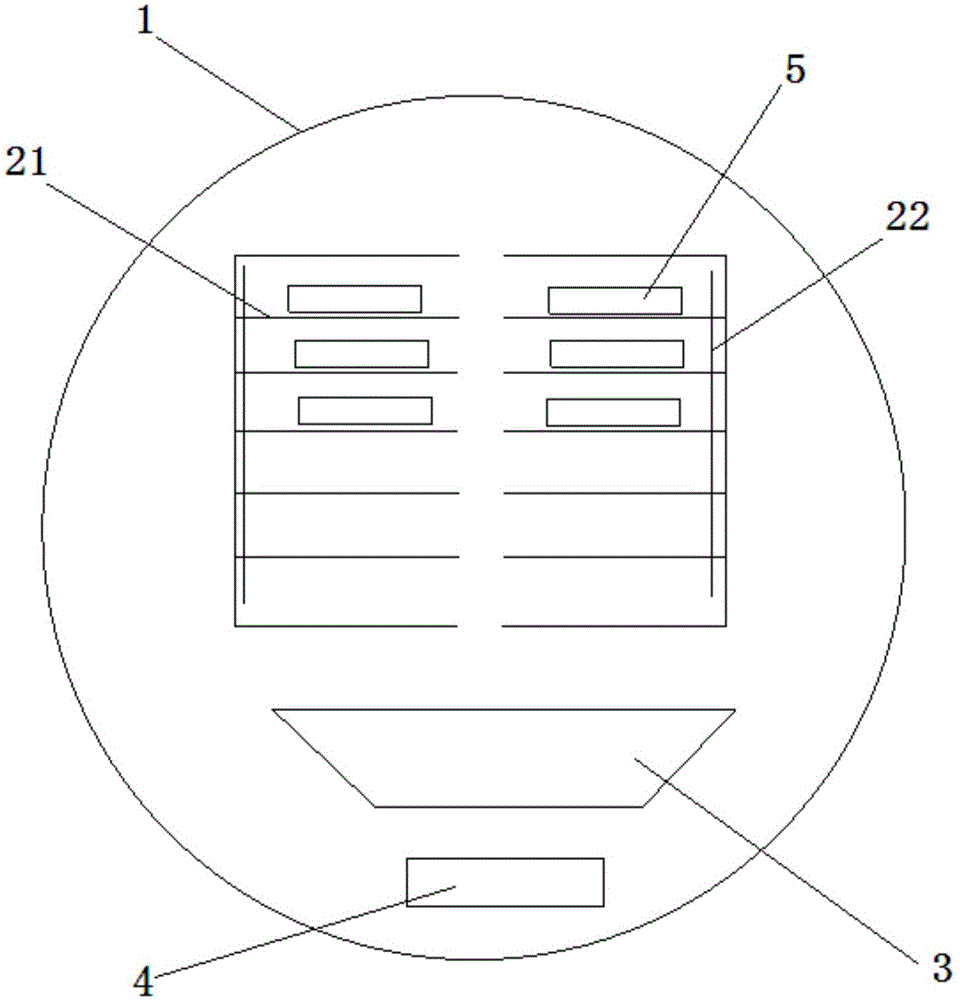

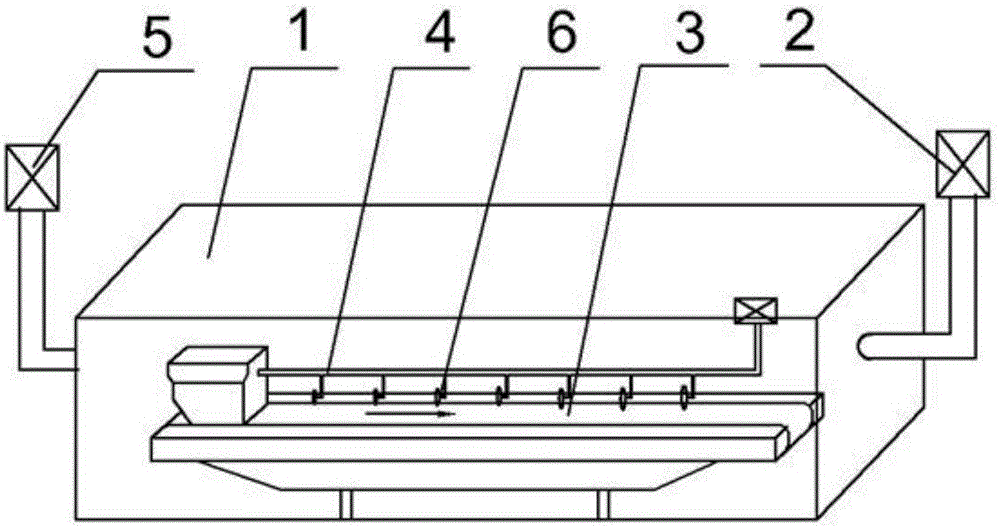

Three-temperature section food quick freezing method and three-temperature section food quick freezer

InactiveCN102058139ADoes not affect flavorUniform temperature distributionFood processingFood preservationFood deliveryEngineering

The invention discloses a three-temperature section food quick freezing method and a three-temperature section food quick freezer, aiming to reduce the power consumption of a refrigerating system in the quick freezing process and achieve the purpose of energy saving. The quick freezer comprises an quick freezer body and a refrigerating system, wherein the inside of the quick freezer body is provided with a food delivery device; the quick freezer body is provided with a feed port and a discharge port; the inside of the quick freezer body is separated into three chambers including a precooling chamber, a crystallization chamber and a cryogenic chamber in sequence by insulating materials or metal partitions; and the insides of the precooling chamber, the crystallization chamber and the cryogenic chamber are respectively provided with an evaporator and a cooling fan. By using the quick freezing method and the quick freezer, food passes through the precooling chamber, the crystallization chamber and the cryogenic chamber with three temperature sections in sequence to become quick-frozen food, the temperature distribution in each chamber is more uniform, and the temperature difference is small, thereby achieving the purpose of energy saving.

Owner:TIANJIN UNIV OF COMMERCE

Preparation method of vacuum low-temperature deep-fried edible mushrooms

ActiveCN108378270AMaintain nutrientsAvoid lostFood freezingFood ingredientsDeep fryingEdible mushroom

The invention discloses a preparation method of vacuum low-temperature deep-fried edible mushrooms, and belongs to the technical field of processing of leisure foods. The preparation method comprisesthe following steps of firstly, performing ultrasonic wave-light wave united treatment on edible mushrooms with a salt solution, then performing ultrasonic wave-vacuum-ultrasonic wave multi-stage immersing, performing quick freezing, performing vacuum low-temperature deep-frying, and performing deoiling to make edible mushroom crisps of which the oil content is only 5-7%. Conventional blanching with hot water and fixation are not adopted, so that the nutrient components of the materials can be maintained to the maximum extent; and a multi-stage immersing technology is adopted, so that the immersing efficiency is improved, and the oil content of products can be notably reduced. The vacuum low-temperature deep-fried edible mushrooms is low in preparation cost, high in puffing rate of products and good in sense organ quality.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

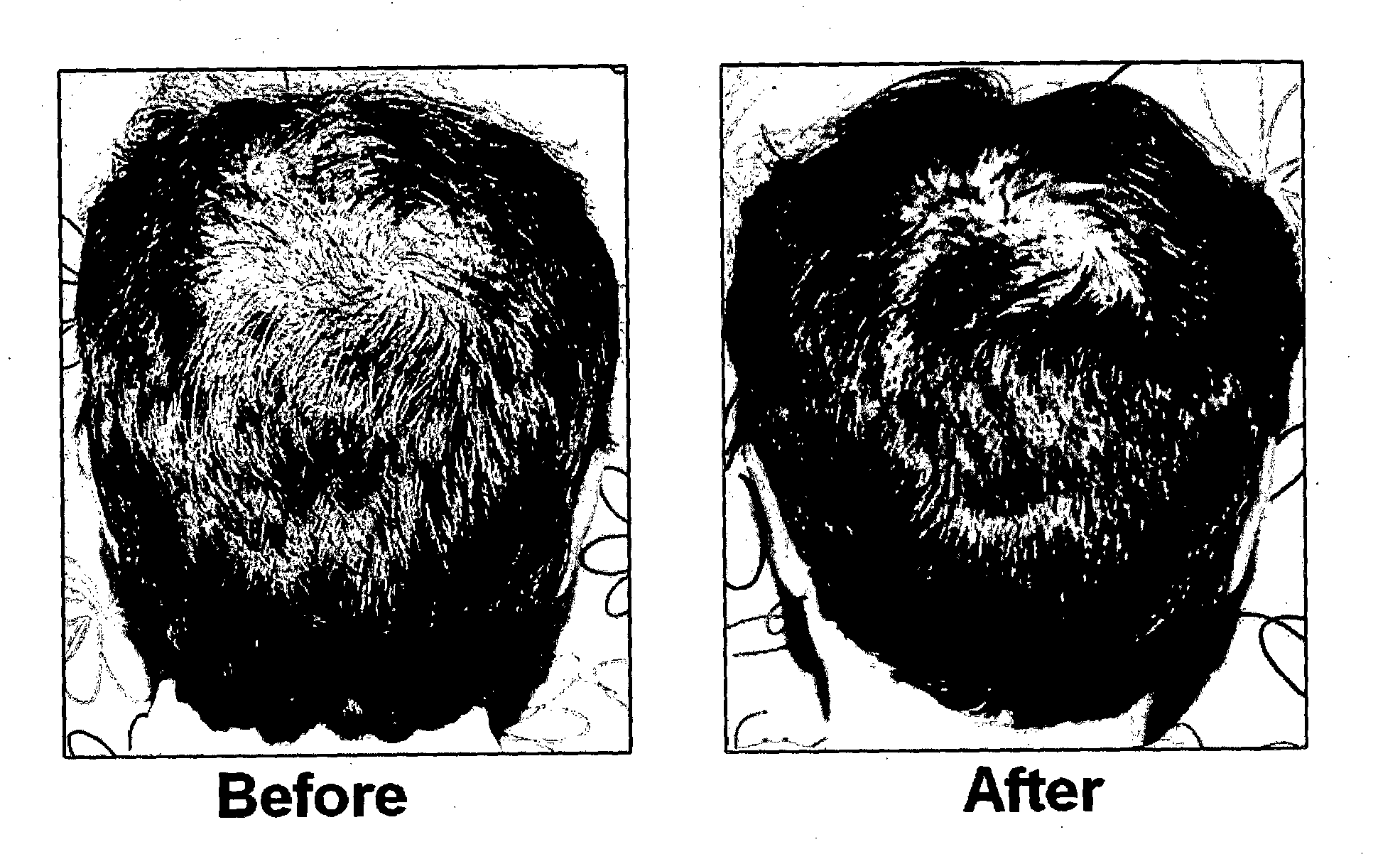

Method of preparing a growth factor concentrate derived from human platelets

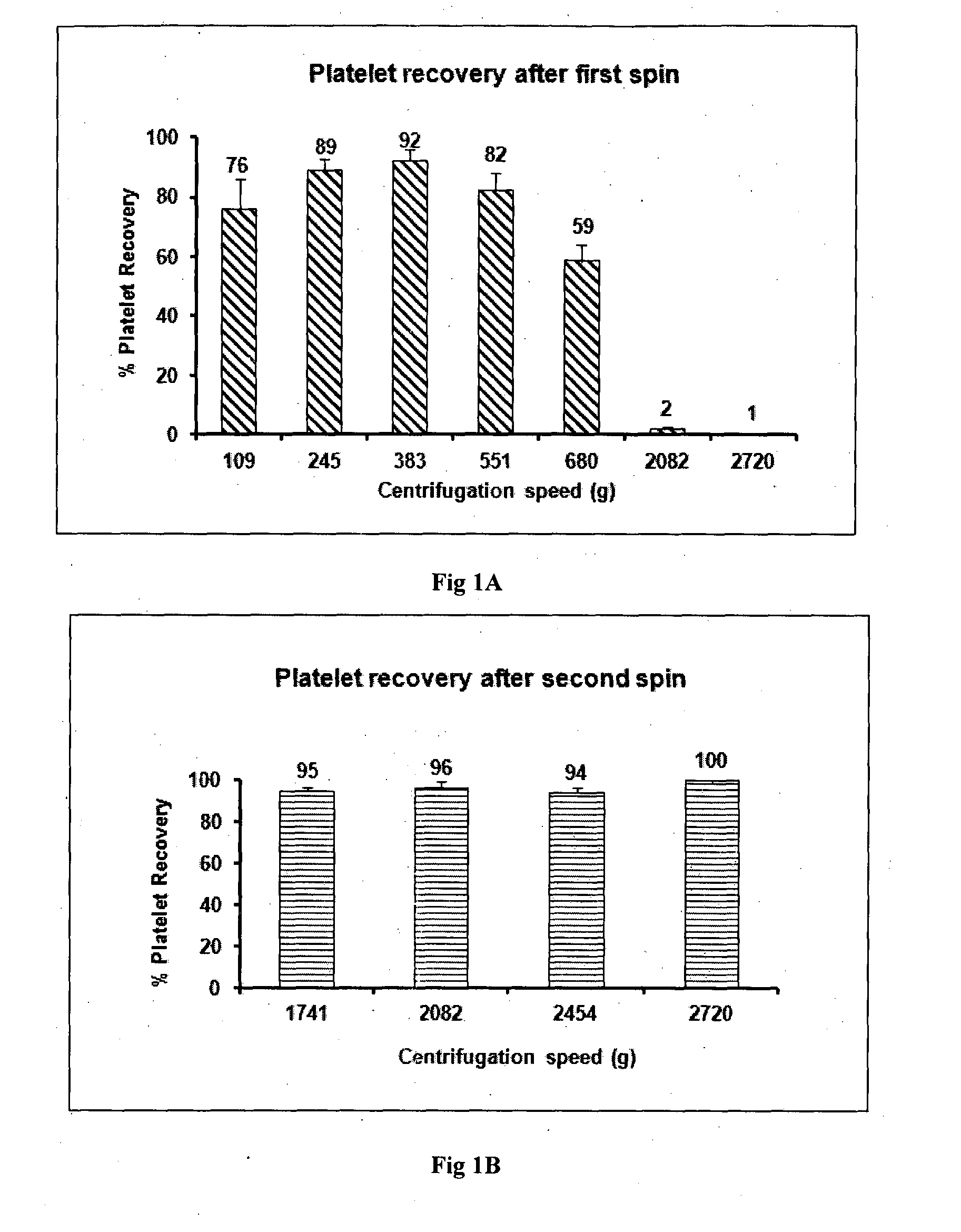

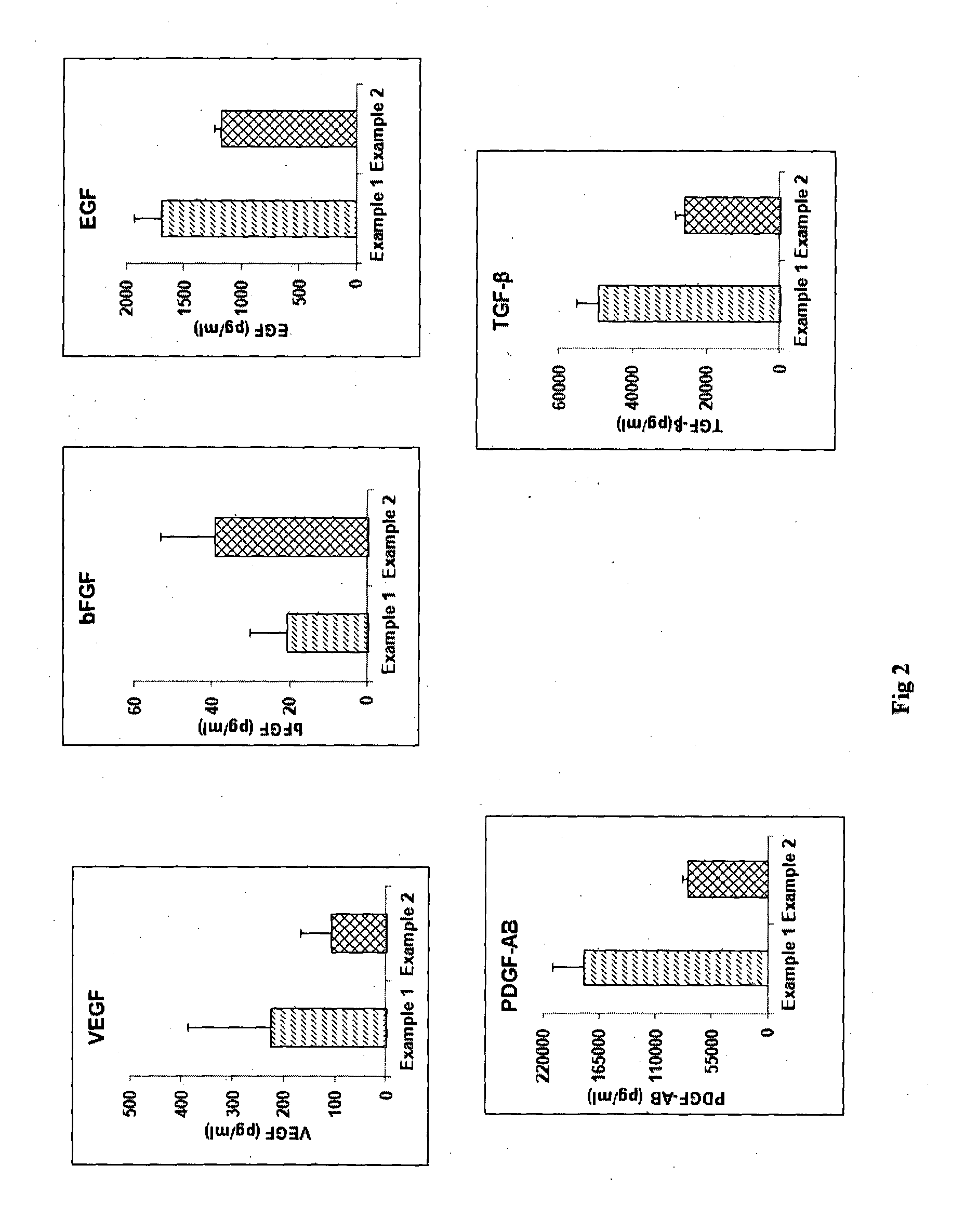

The invention relates to a method of preparing an intra-dermally, intra-articularly, sub-dermally or topically administrable growth factor concentrate derived from human platelets. The method comprises the steps of suspending human platelets in multiple electrolyte isotonic solution; snap-freezing the suspension; thawing the frozen suspension; and sterile-filtering the suspension. In particular, in this method, a fixed number of platelets is suspended in a fixed volume of multiple electrolyte isotonic solution to obtain the required concentration of growth factors in the growth factor concentrate, snap-freezing of the suspension is carried out at a temperature of −120° C. to −200° C., thawing of the frozen suspension is carried out at 25° C. to 37° C., and cellular debris are separated from the thawed suspension and the resultant suspension of growth factors is diluted with an isotonic medium before sterile-filtering.

Owner:KASIAK RES PVT

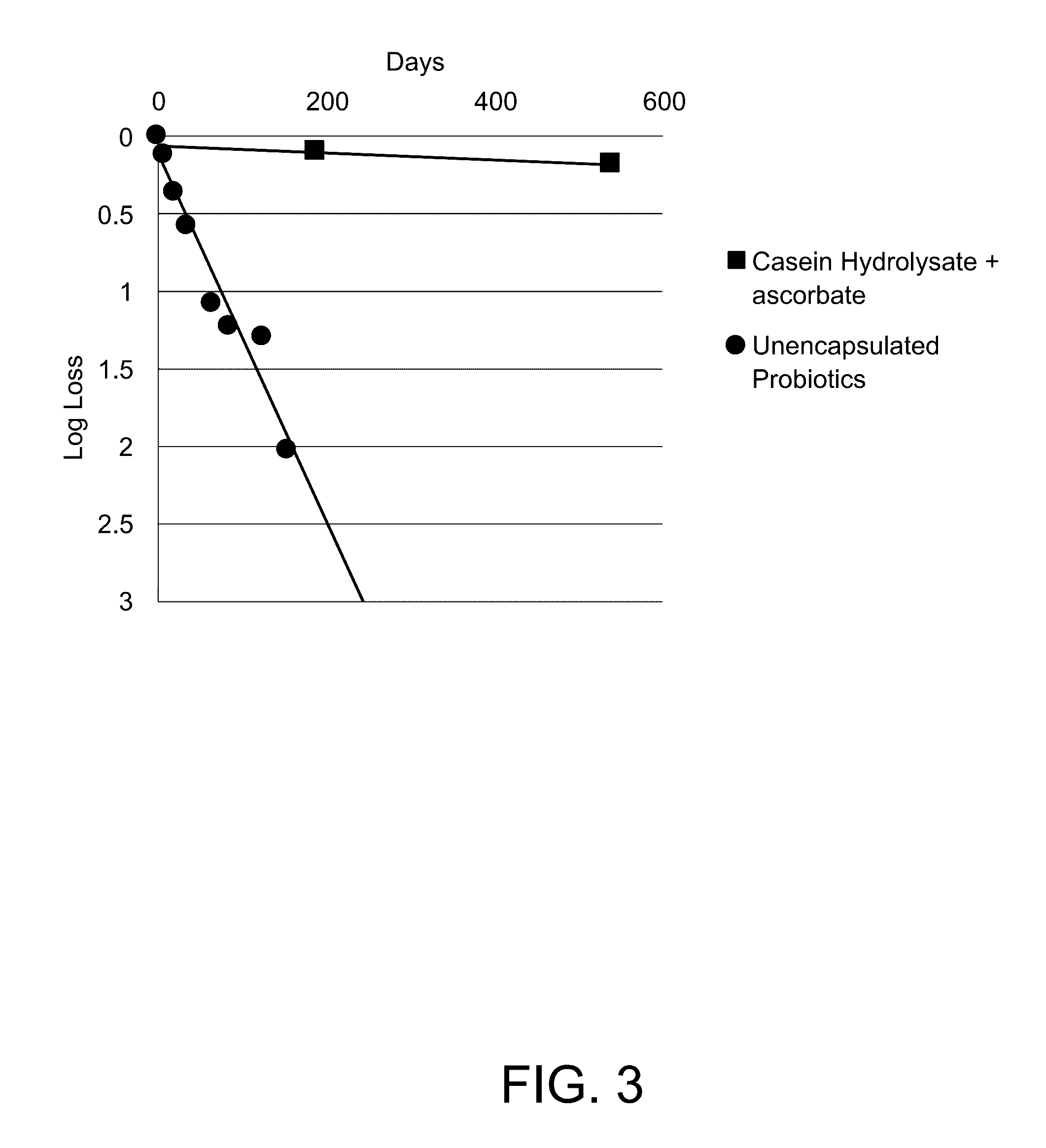

Stabilizing composition for biological materials

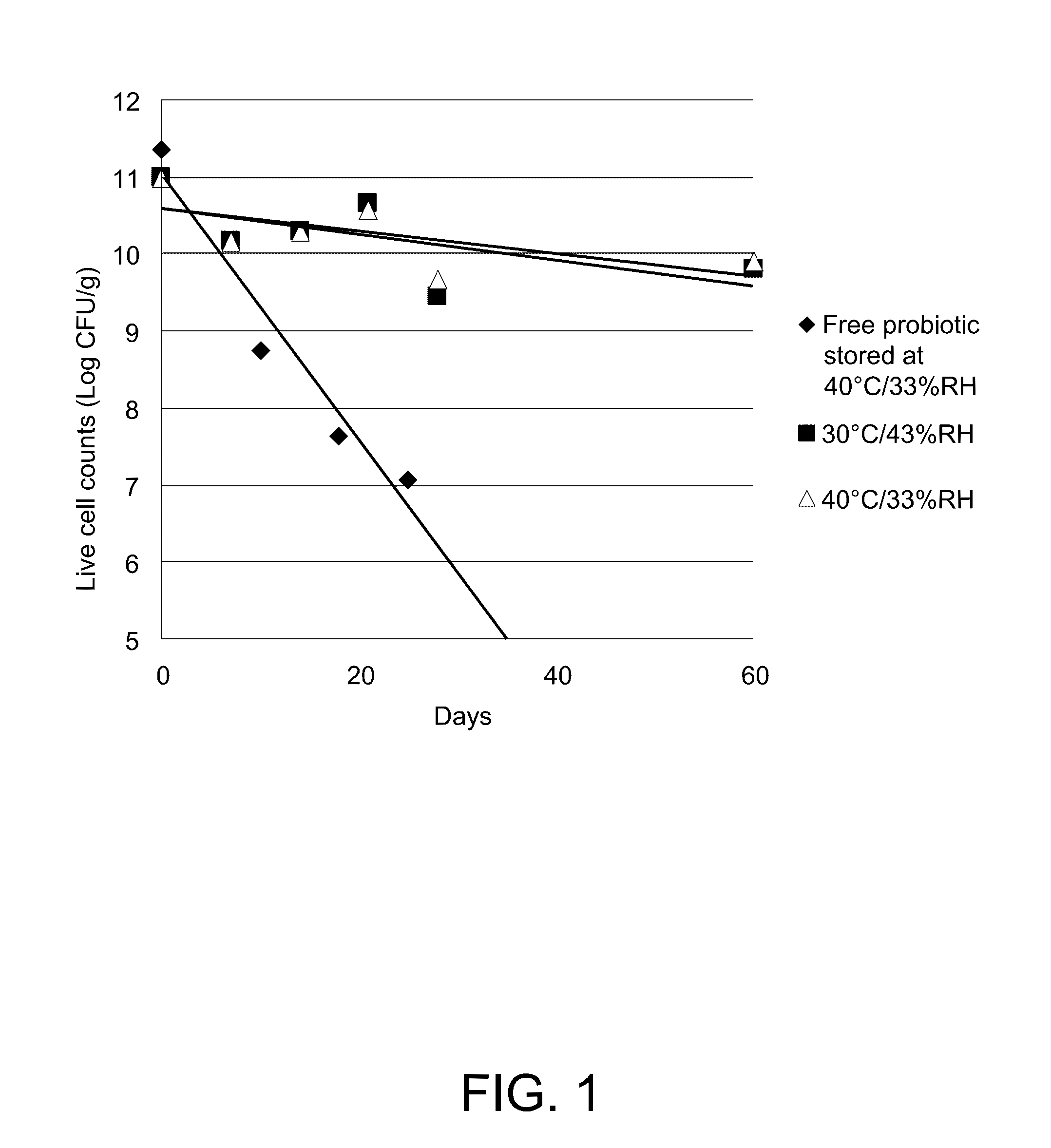

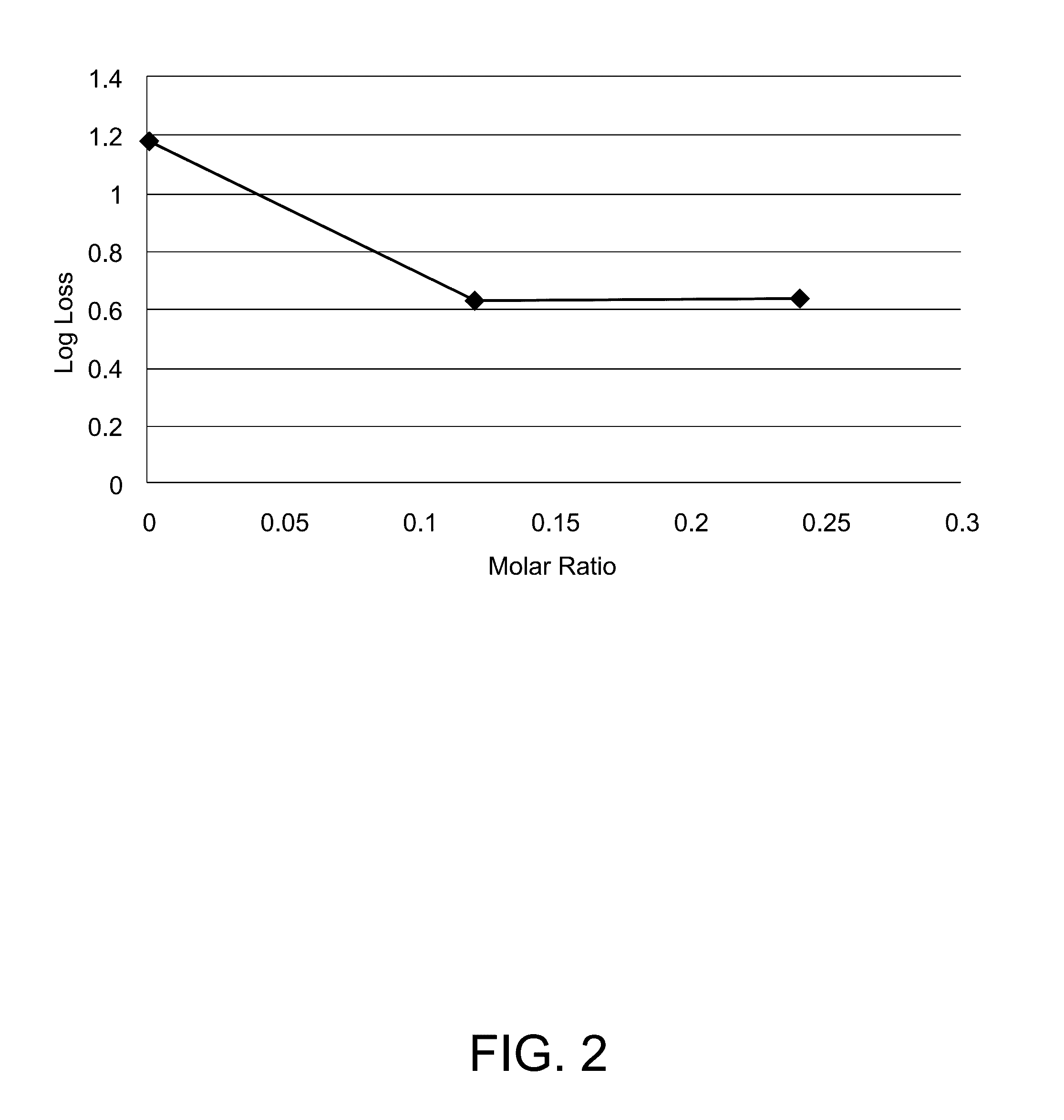

Dry stabilizing compositions for bioactive materials include sugars and hydrolyzed proteins, and may be formed into tablets or other forms providing enhanced stability for the bioactive material. Compositions containing the bioactive materials may be produced by a method that includes (a) combining the bioactive material with other ingredients in an aqueous solvent to form a viscous slurry; (b) snap-freezing the slurry in liquid nitrogen to form solid frozen particles, beads, droplets or strings; (c) primary drying by water removal under vacuum of the product of step (b) while maintaining it at a temperature above its freezing temperature; and (d) secondary drying of the product of step (c) at maximum vacuum and a temperature of 20° C. or higher for a time sufficient to reduce the water activity to below 0.3 Aw.

Owner:ADVANCED BIONUTRITION CORP

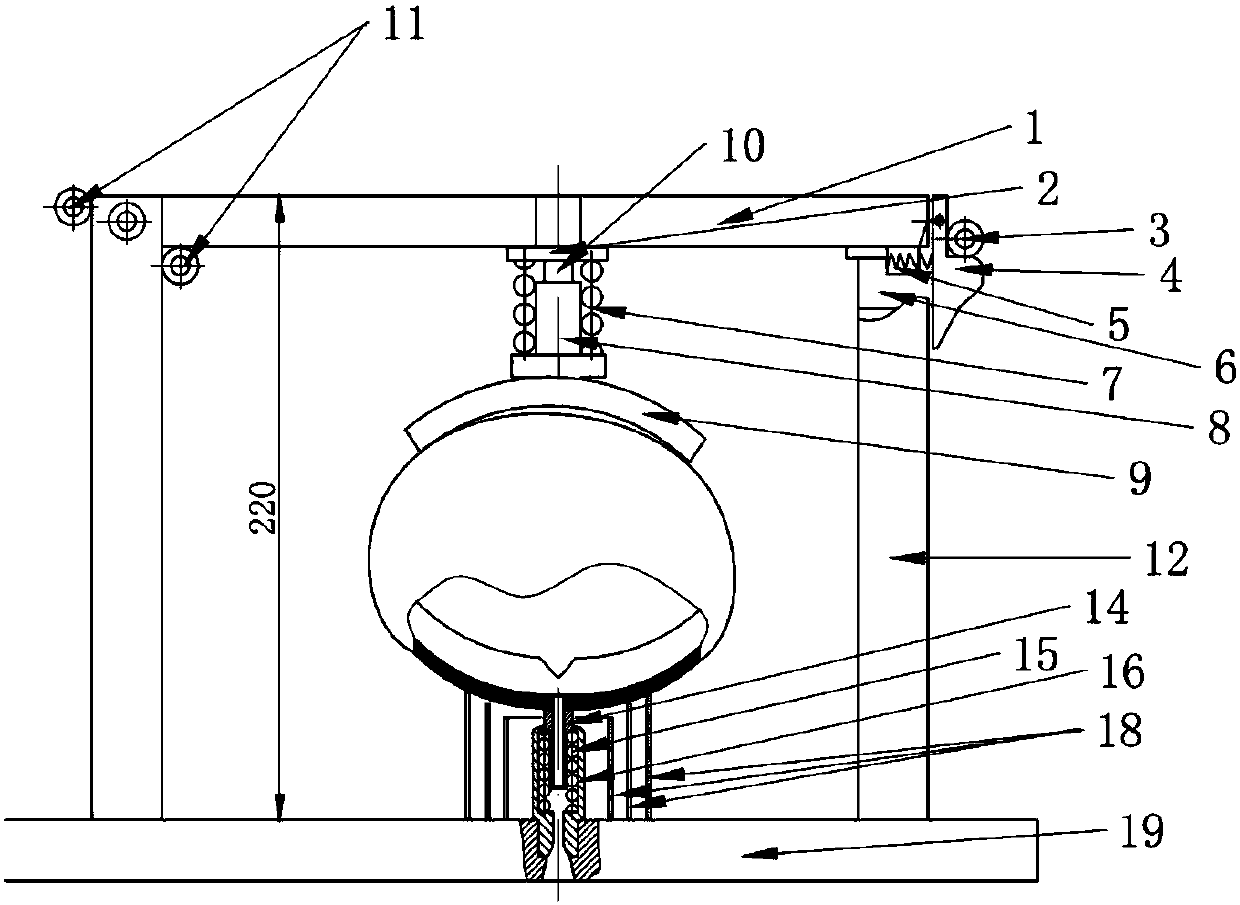

Quick-freezing fresh-keeping method and tunnel-type fresh-keeping quick-freezing machine

PendingCN109990543AFreeze fast and keep freshGood fresh-keeping effectLighting and heating apparatusStationary refrigeration devicesQuick FreezeEngineering

The invention discloses a quick-freezing fresh-keeping method and a tunnel-type fresh-keeping quick-freezing machine. The tunnel-type fresh-keeping quick-freezing machine comprises a fixing frame, a transmission roller shaft and a storehouse body, wherein the storehouse body is provided with a transmission mesh belt; the storehouse body is arranged on the fixing frame; a fresh-locking chamber anda freezing chamber are arranged in the storehouse body; the fresh-locking chamber and the freezing chamber are mutually connected; a liquid nitrogen spraying device is arranged in the fresh-locking chamber; a plurality of atomizing spray heads are arranged on the liquid nitrogen spraying device; an air cooling device is arranged in the freezing chamber; the storehouse body is provided with a regulating and controlling system electrically connected with the liquid nitrogen spraying device and the air cooling device; and the two ends of the storehouse body are provided with a feeding port and adischarging port. According to the quick-freezing fresh-keeping method and the tunnel-type fresh-keeping quick-freezing machine, the mechanical compression refrigeration and the liquid nitrogen refrigeration are effectively combined, a frost protection layer is formed on the surface of material by spraying liquid nitrogen to protect the moisture of the material from losing so as to ensure the freshness of the material, and then a mechanical compression refrigeration is adopted to carry out deep refrigeration so as to avoid dehydration of the surface of the material due to direct air cooling soas to ensure the freshness and taste of the material; and meanwhile, the fresh-locking and fresh-keeping effect are achieved, full-automatic operation is achieved according to set parameters, and energy consumption is reduced.

Owner:广州鲜之源生态冷链技术有限公司

Method for freezing storage of fresh rose flowers

InactiveCN106719606AReduce moisture contentSlow coolingDead plant preservationRefrigerationPre cooling

The invention discloses a method for freezing storage of fresh rose flowers. The method comprises 1) picking: picking fresh rose flowers before sunrise, 2) precooling: timely feeding the picked rose flowers into an air-conditioned room at a temperature of 8-10 DEG C and carrying out spreading pre-cooling for 2-3h, 3) encasement: putting the pre-cooled rose flowers into a foam box, mixing the rose flowers and a food-grade desiccant in the foam box, putting 2-4 frozen biological ice packs in the foam box at height spaces of 20-25cm, 4) sealing: sealing the foam box after encasement, 5) quick-freezing: immediately feeding the sealed foam box into a refrigeration house, and carrying out freezing at a temperature of -20 DEG C, and 6) freezing storage: carrying out freezing storage on the quick-frozen rose flowers at a temperature of -5 to 0 DEG C. The method changes the salted storage method of the rose flower, uses the quick freezing and freezing storage technology to make the rose flower in the dormant state and delays the cell physiological activity so that the freshness preservation is realized. After storage for 60 days, the flowers still retain original color, aroma and quality.

Owner:CROP RES INST OF FUJIAN ACAD OF AGRI SCI

Quick-freezing and preserving method of daylily

InactiveCN109169850AMeet the requirements of cooling and dehydrationSolve the problem of pine bud bloomingFood freezingFood thermal treatmentDaylilyWater cooling

The present invention discloses a quick-freezing and preserving method of daylily. The quick-freezing and preserving method of the daylily comprises four steps of enzyme deactivating, cooling, quick-freezing and packaging. During the enzyme deactivating process, a steam box is heightened to solve a problem of non-uniform curing of the enzyme-deactivating of the daylily and improves enzyme-deactivating efficiency; during the cooling, processes of water cooling, dehydrating, wind cooling and dehydrating are conducted; the water cooling and wind cooling are combined; so that before the daylily enters a quick-freezing device, the daylily reaches a requirement of cooling and dehydrating after the enzyme-deactivating of the daylily; and at the same time, a problem of flower bud loosening and blooming during the cooling process after the enzyme-deactivating of the daylily is solved.

Owner:湖南吉祥食品有限公司

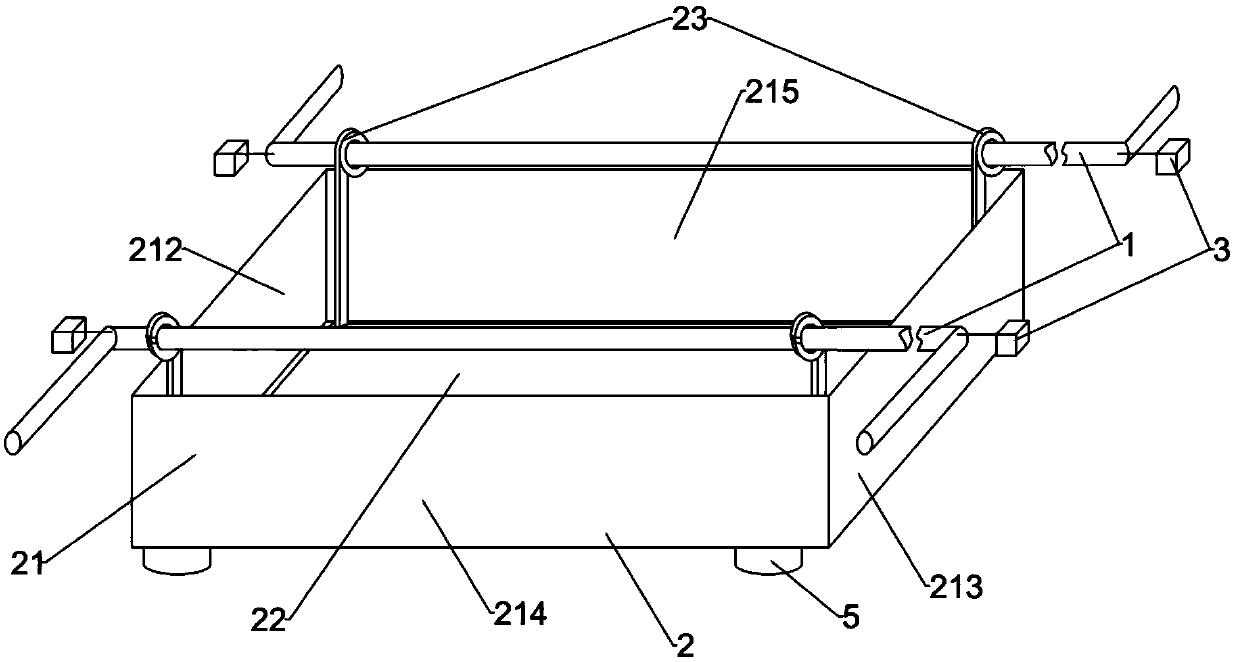

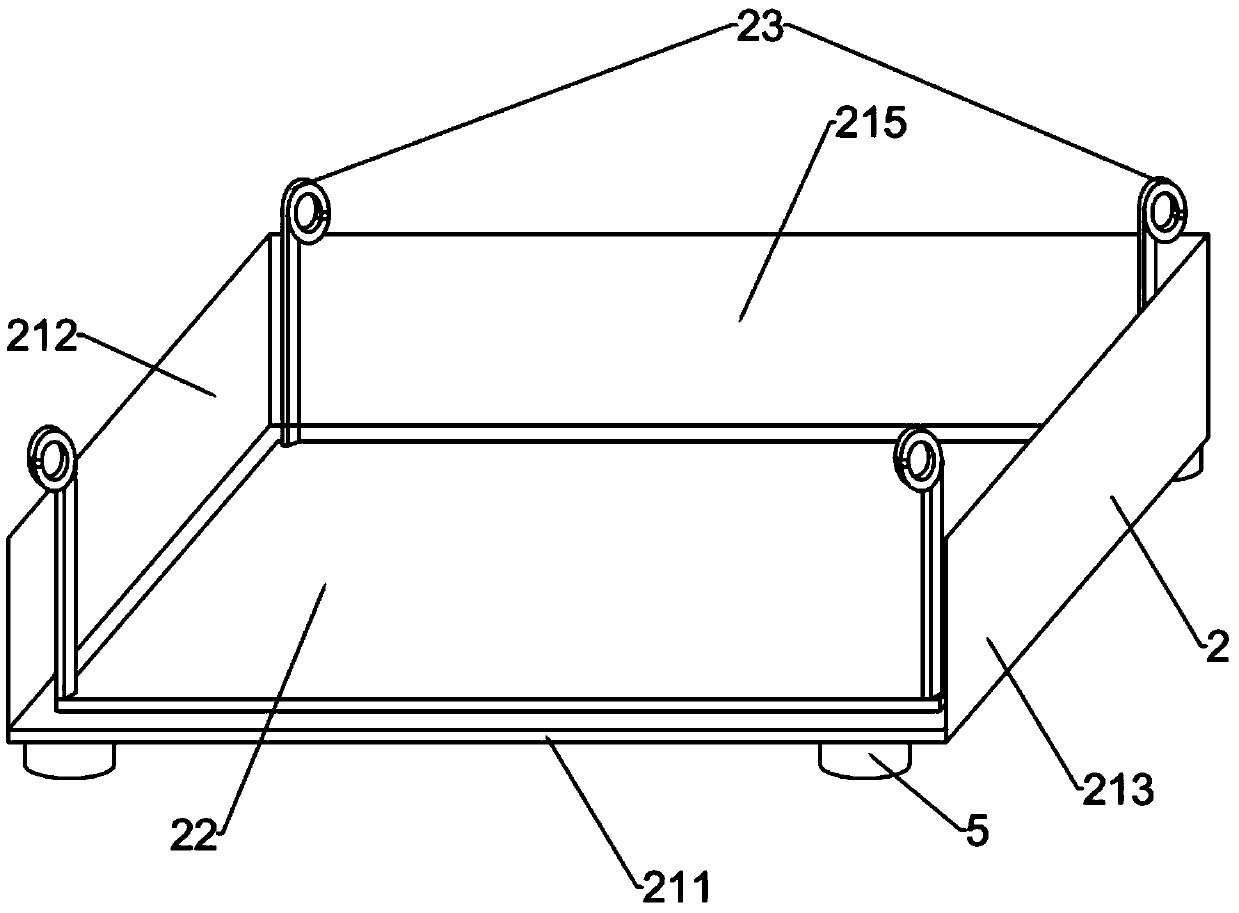

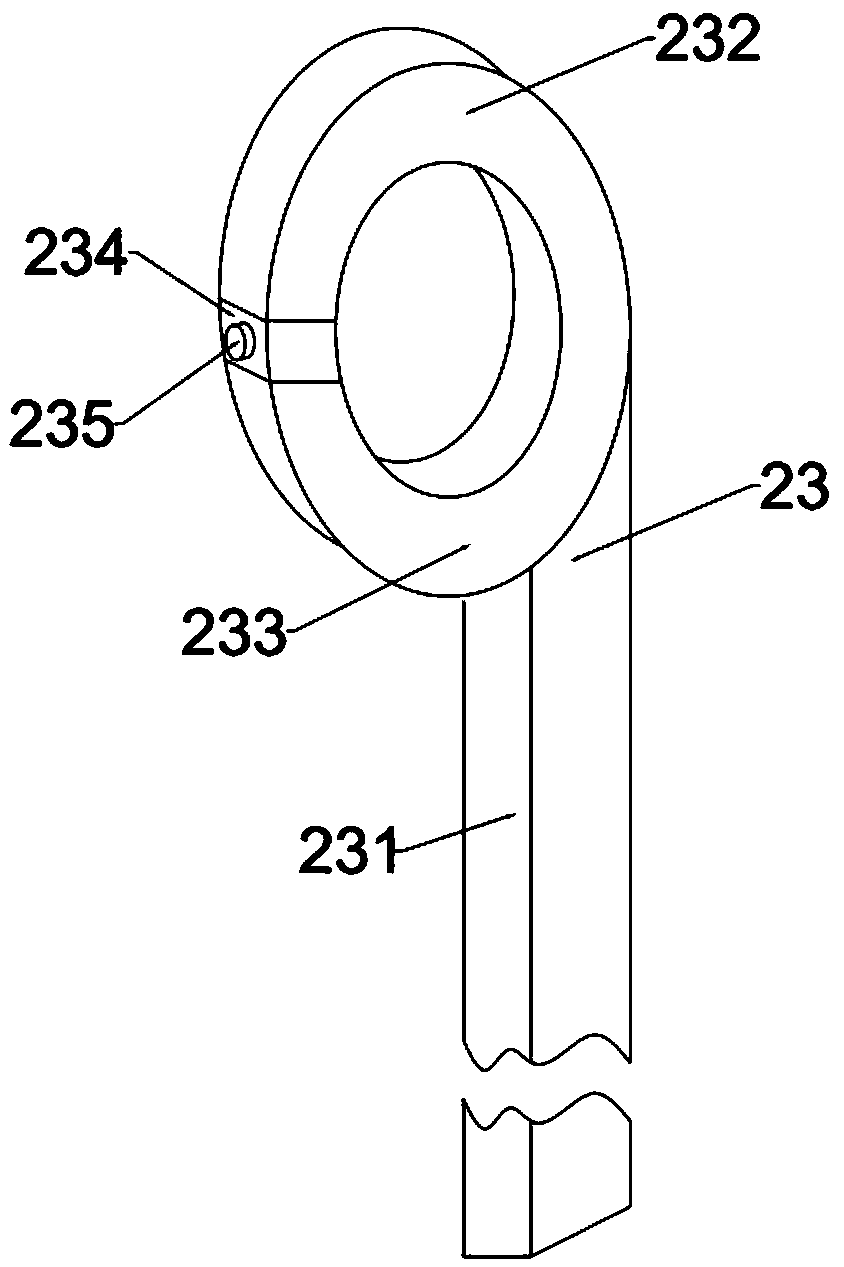

Bombay duck liquid nitrogen ultralow temperature quick-freezing device and quick-freezing fresh-keeping method thereof

InactiveCN109527063AFreeze evenlyGuaranteed qualityMeat/fish preservation by freezing/coolingQuick FreezeElectricity

The invention discloses a bombay duck liquid nitrogen ultralow temperature quick-freezing device and a quick-freezing fresh-keeping method thereof. The device includes a liquid nitrogen quick-freezer,two parallel vibration rods installed on the liquid nitrogen quick-freezer and a plurality of product freezing frames for quick-freezing of products. Each product freezing frame includes a frame body, a placement plate disposed in the frame body, and a plurality of suspension units arranged on the placement plate. Both ends of all the vibration rods are equipped with vibration motors, all the vibration motors are electrically connected to a master controller of the liquid nitrogen quick-freezer. The placement plate is suspended on the two vibration rods through the suspension units. Accordingto the invention, cleaning, soaking, ultra-low temperature quick-freezing, ice plating, vacuum packaging, cryopreservation and other processes are adopted in order to avoid wrinkling and chapping ofthe fish skin, and at the same time the original condition, color and freshness of bombay duck can be maintained. The vibration rods drive the suspension units and the placement plate to vibrate, so that the bombay duck can be frozen more evenly, and the overall freezing quality of bombay duck can be ensured.

Owner:浙江大洋兴和食品有限公司

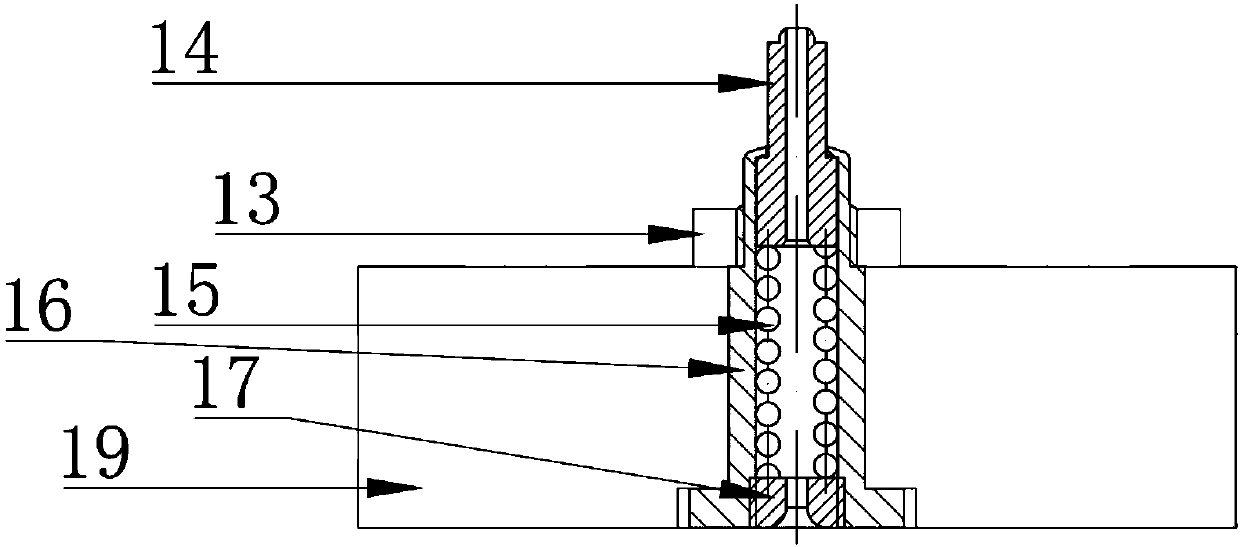

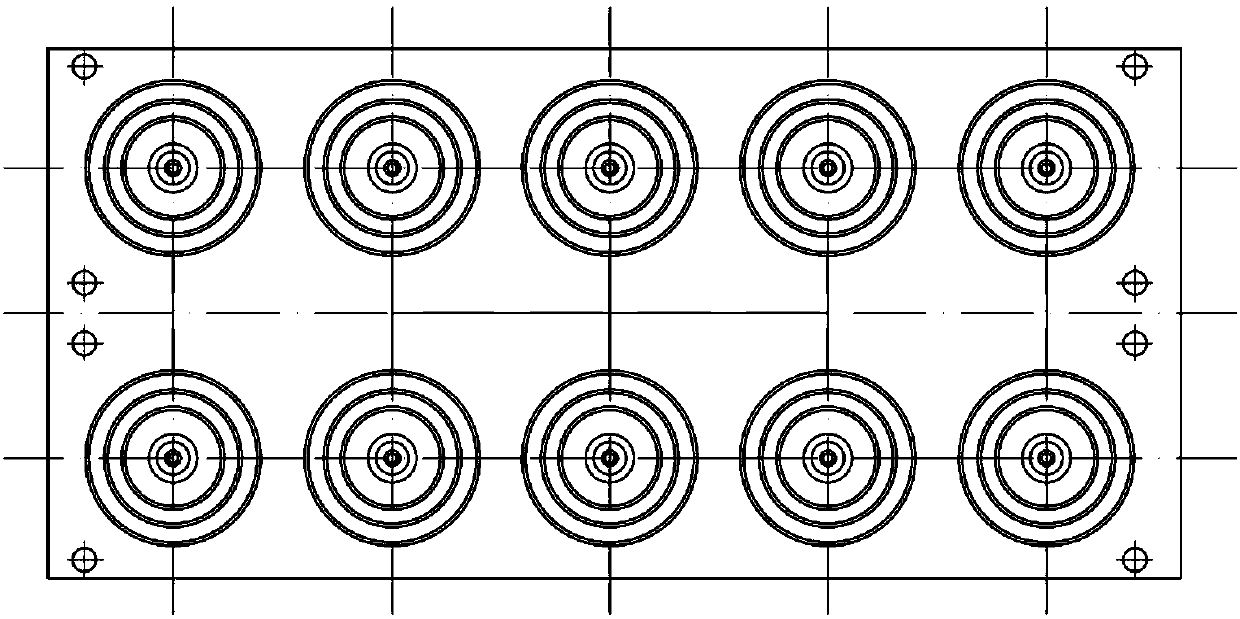

Automatic vacuum bacteria-free water taking mechanical equipment for coconuts and sealed filling technology

PendingCN107744149AAchieving and Avoiding OxidationAchieving and Avoiding PollutionJuice extractionBottle-handling machinesEngineeringMechanical equipment

Endemism and tightness of coconut germ openings are used, mechanical drilling is not needed, a straw of which the diameter is smaller than that of the germ openings directly enters coconut flesh, andpure coconut water is absorbed; a unit positioning plate suit is used for precisely fixing the position of the coconut germ openings; a conveyor belt is used for conveying the unit positioning plate suit to complete the entire water absorption process; a vacuum water taking principle is used for automatic water absorption; data detected by a pH detection instrument is used for diverting the coconut water; and an automatic procedure is used for controlling the entire process. Besides, a quick-frozen sterilizing technique and a low-temperature refrigerating technique are used for a coconut watertreatment technology, any preservative and additive do not need to be added, and polypeptidase, electrolyte, trace elements and the like in the coconut water are not destroyed, so that the coconut water is sufficiently used, and value transformation is realized; and the problems that in the production trade of the coconuts, the coconut water is difficult to preserve, the coconuts are difficult tomake into commercialized products are solved, and a blank for domestic and abroad techniques is filled.

Owner:HAINAN HUITANG IND INVESTMENT CO LTD

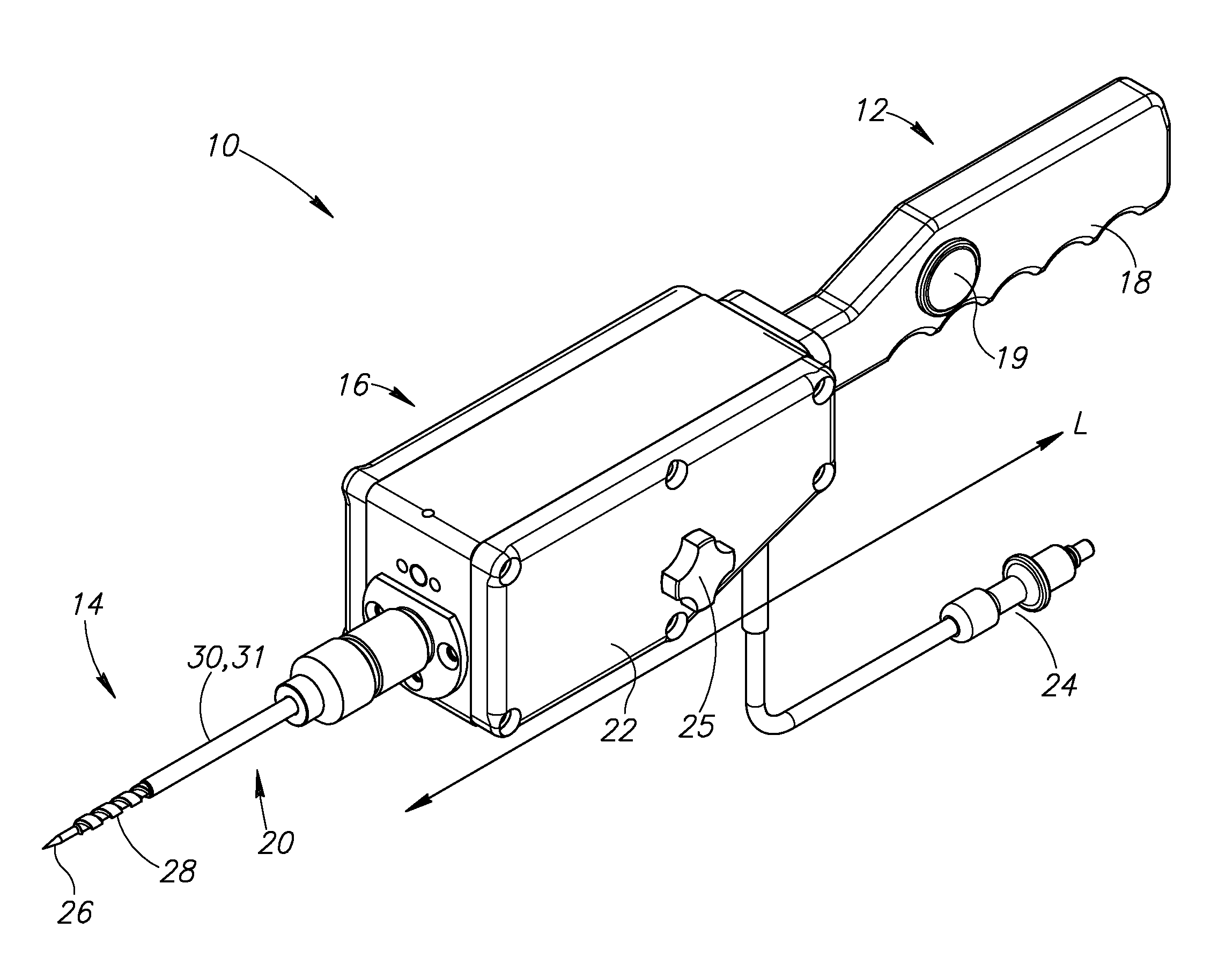

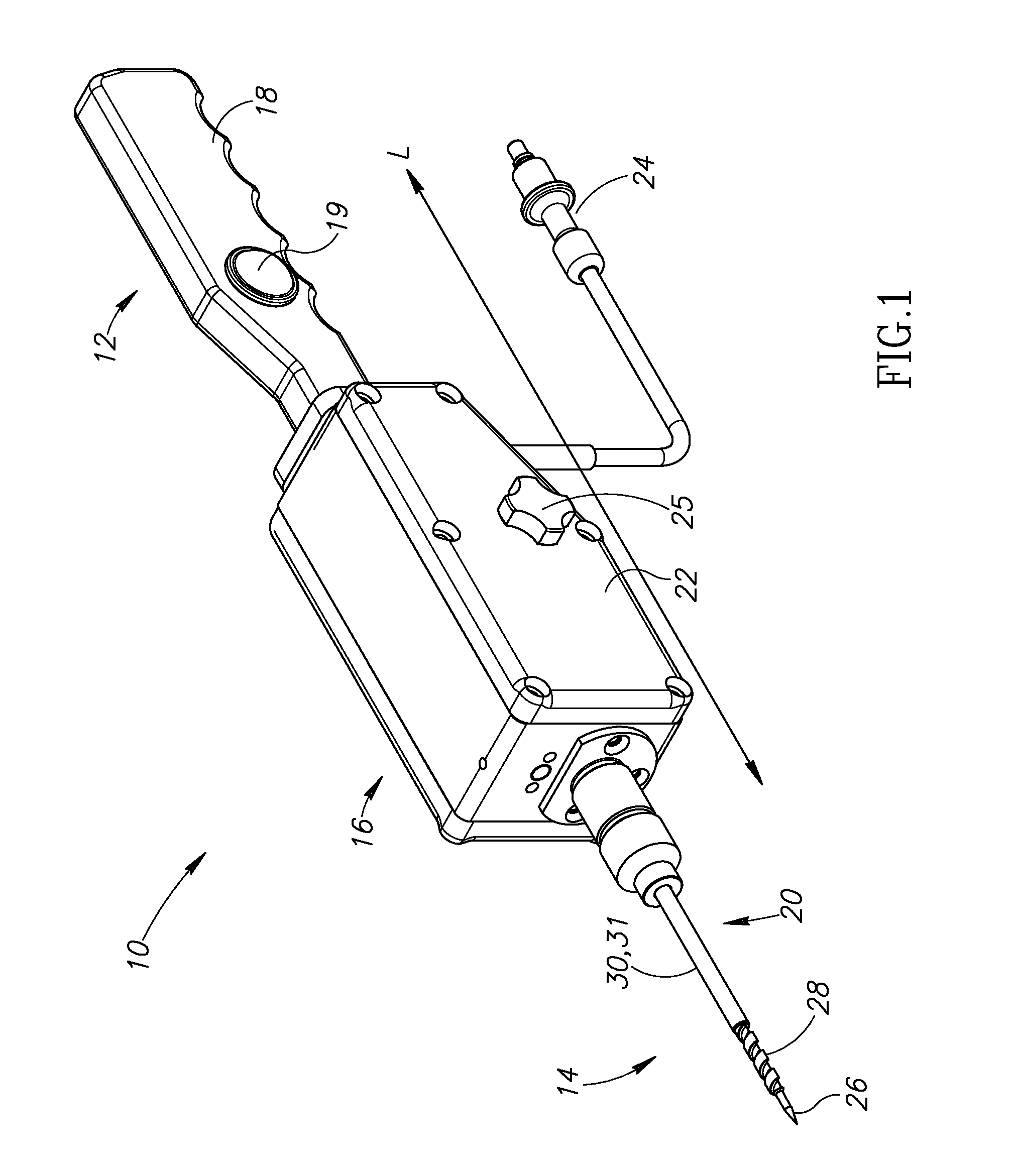

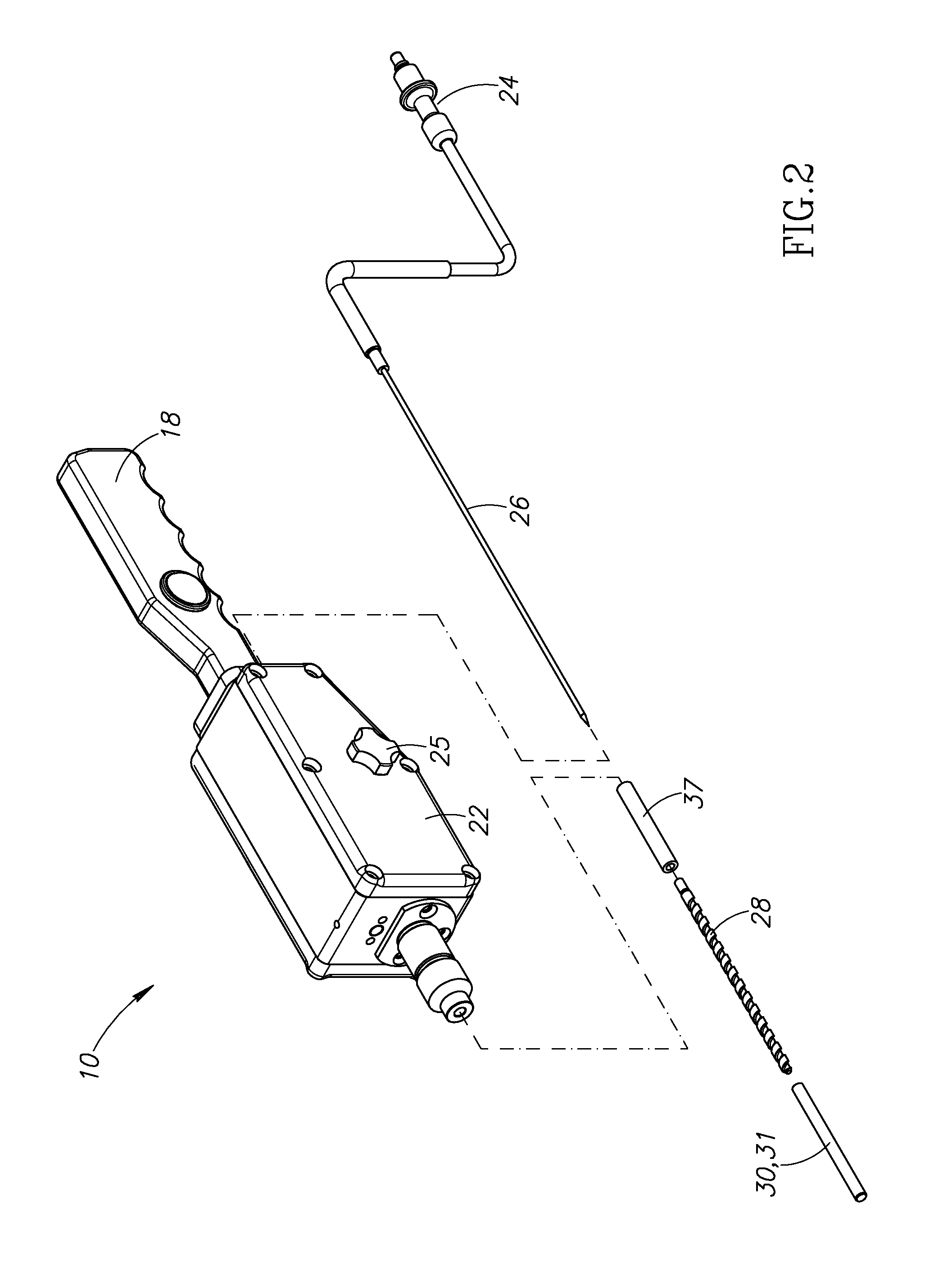

Cryogenic biopsy system and method

ActiveUS20120322070A1Avoid curlMicrobiological testing/measurementSurgical needlesBiopsy devicePathology diagnosis

A cryogenic biopsy device is configured to provide thin, frozen tissue samples, which may be viewed under a microscope and selected for biomarker analysis. The device is configured to provide slices which are less than 50 micrometers in thickness, while snap-freezing the tissue and maintaining the sample in a deep-frozen state until it reaches the pathology lab for further processing. Alternatively, thicker slices can be harvested by the device and additional sectioning can be done in the pathology lab by using cryomicrotome. The device of the present invention may be used in rigid instruments and in flexible devices, such as endoscopes, for example, and may be suitable for single use or multiple use.

Owner:NEVO EREZ

Snap-freezing process method for vegetables rich in flavonoid

InactiveCN105230771AReduce negative impactStrengthen the basic skeletonFruits/vegetable preservation by freezing/coolingNutritive valuesChloride

The invention discloses a snap-freezing process method for vegetables rich in flavonoid. The method comprises the following steps: 1) selecting fresh vegetables without damages on surfaces as raw materials; 2) removing roots of qualified raw materials, cutting off the raw materials, rinsing the cut raw materials with clean water, and draining water; 3) placing the rinsed raw materials in sodium bicarbonate solution for scalding, taking the scalded raw materials out, and draining water; 4) placing the scalded samples in color-protecting liquid to perform color-protecting treatment, and draining water; 5) placing the samples subjected to color-protecting treatment in calcium chloride for brittleness-keeping, rinsing the treated raw materials with cooling water and draining water; and 6) snap-freezing the treated raw materials. When the vegetables snap-frozen with the method is thawed, shrinkage do not occur, the appearance of the vegetables is glossy, the original tissue structure can still be kept, the nutritive value of the vegetables is effectively kept, the shelf life is prolonged, a tedious process of double snap-freezing is avoided, and the production cost is saved.

Owner:YANGZHOU UNIV

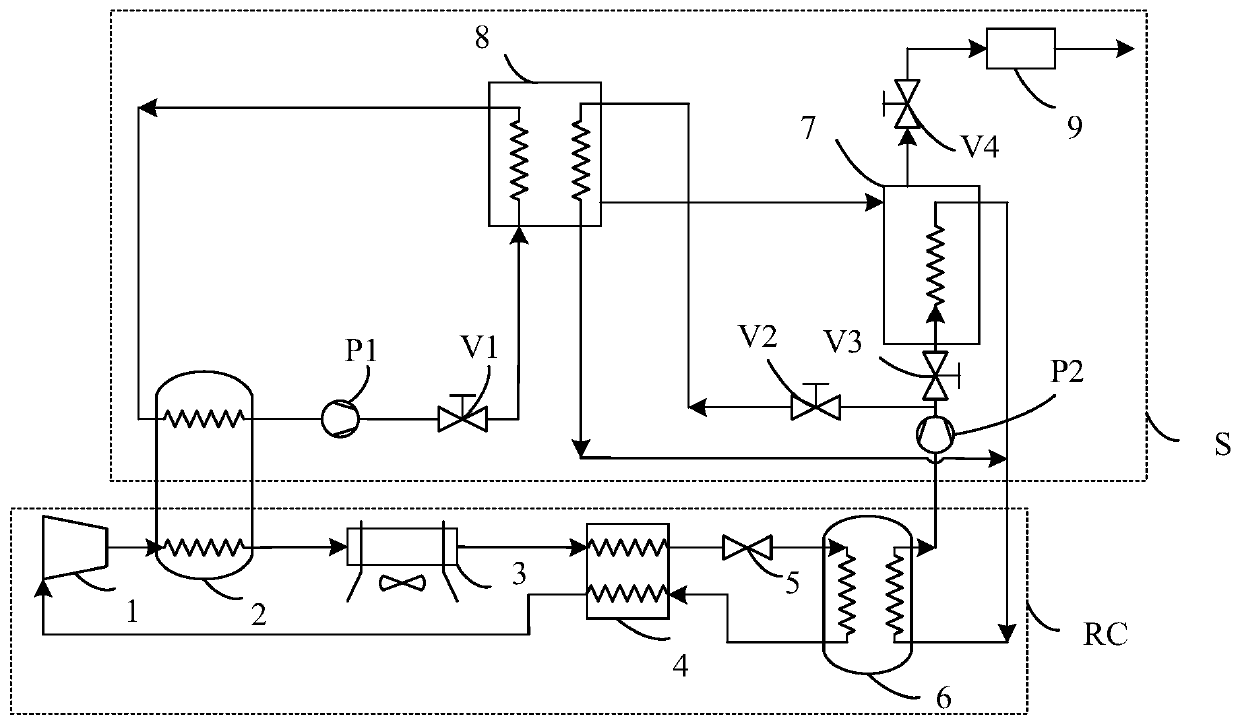

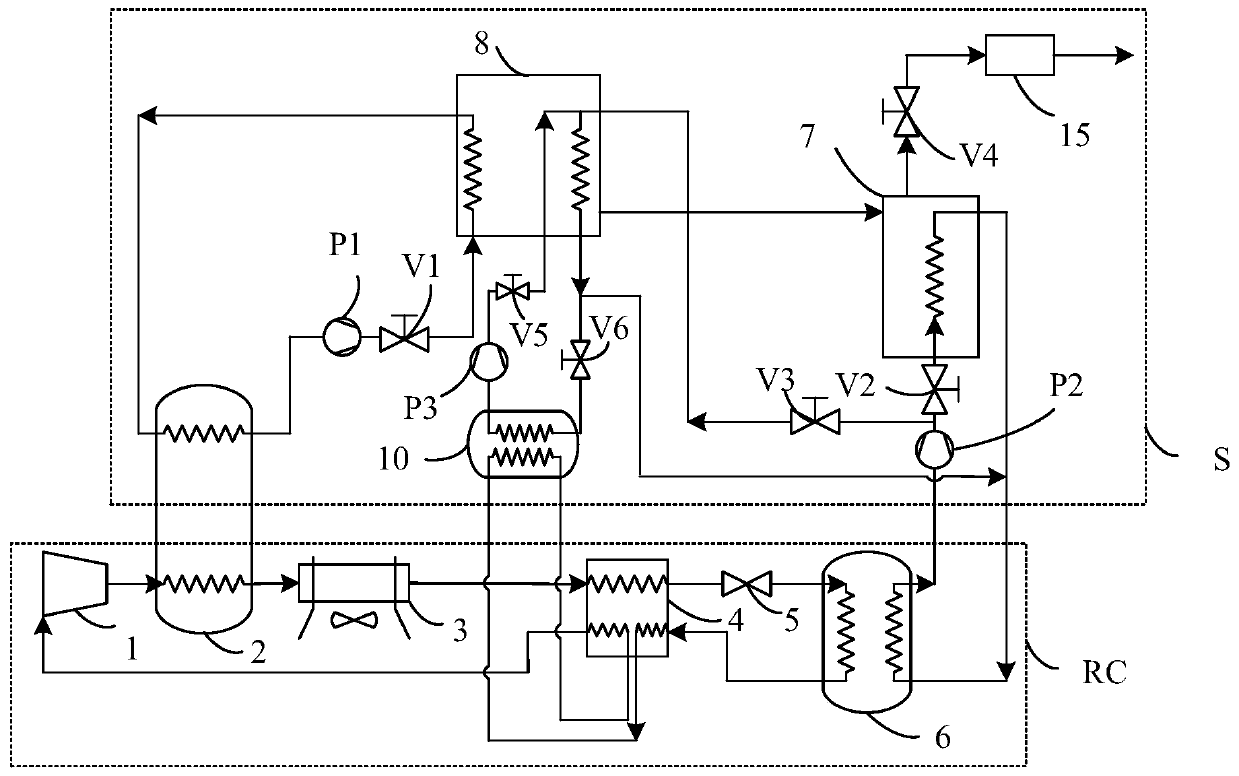

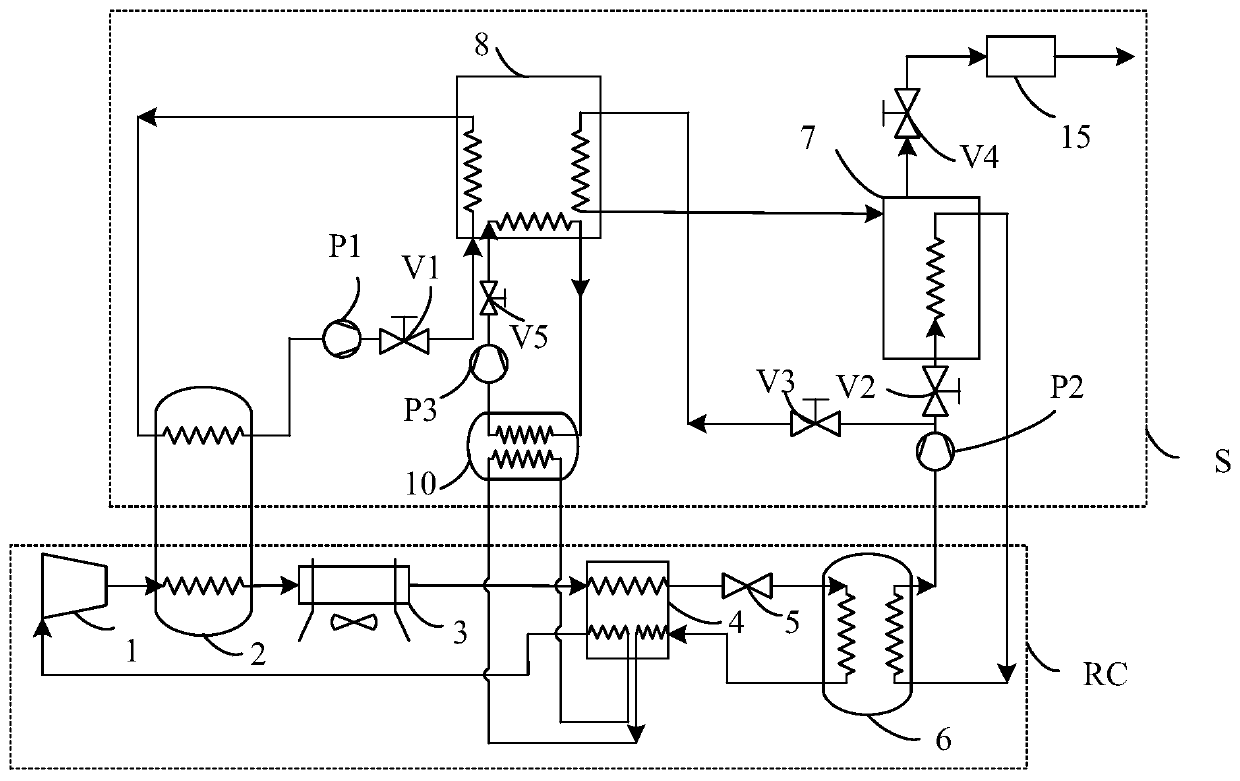

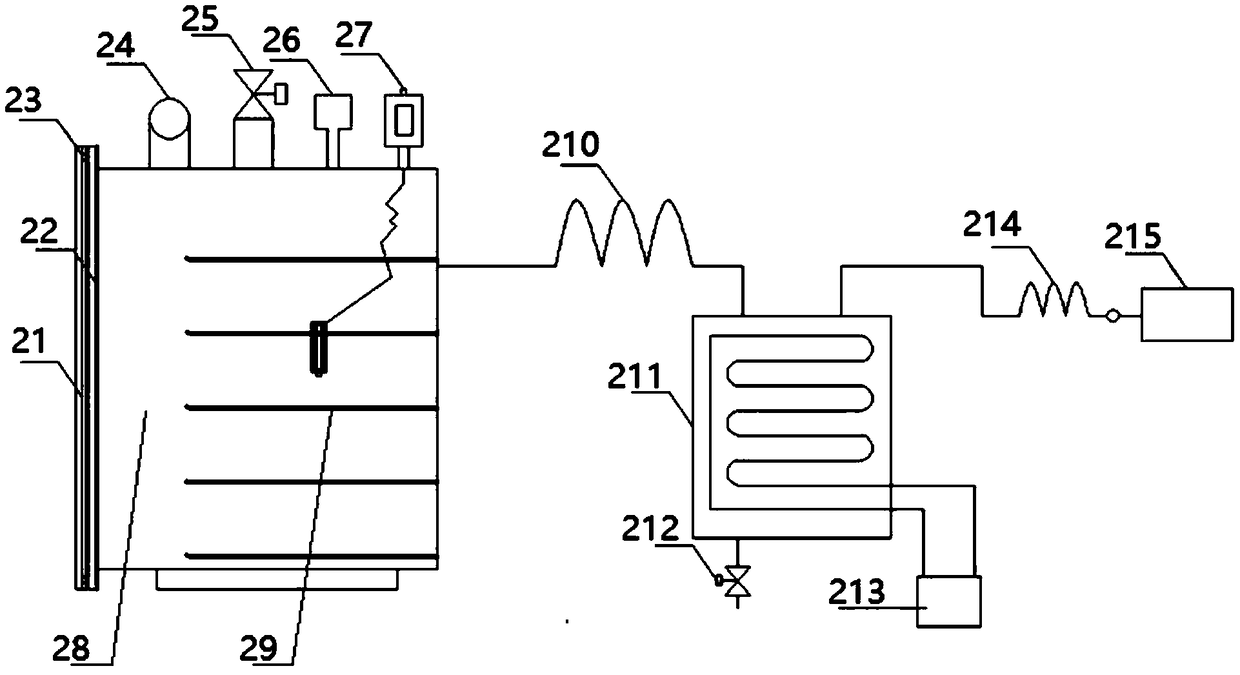

Freeze-drying system

ActiveCN109764641AImprove qualityReduce ambient temperatureDrying solid materials without heatHeat storage plantsElectricity priceFreeze-drying

The invention discloses a freeze-drying system. According to the freeze-drying system, a mechanical mixed-working-medium low-temperature refrigeration unit (RC) is used to realize ultralow-temperaturequick-freezing of materials, a vacuum freeze-drying unit (S) is used to realize vacuum freeze-drying of the materials, under the action of the mechanical mixed-working-medium low-temperature refrigeration unit (RC) and the vacuum freeze-drying unit (S), a quick-freezing process can be accelerated, the quality of the quick-frozen materials is improved, the freeze-drying technique period is shortened, and the refrigeration energy consumption is reduced; and meanwhile, the freeze-drying system provided by the invention adopts a cold-and-hot storage mode and a cold-and-hot use mode, the peak-valley electricity price difference of the industrial electricity is utilized so as to start low-temperature refrigerators during the night valley electricity period, cold storage and compression heat replace electric heating to provide heat required in drying and desorption processes, the valley electricity is also utilized, the environment temperature at night is low, the operation efficiency of a refrigeration system is relatively high, and energy-saving and electricity-saving effects are thus realized.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for processing cooked dumplings through vacuum-cooling and quick-freezing

InactiveCN102813137AExtended shelf lifeTo achieve the purpose of preservationFood preparationFlavorMicrowave

The invention discloses a method for processing cooked dumplings through vacuum-cooling and quick-freezing, and provides a cooked dumpling making method by using which the food cooling time can be shortened and rapidly gets over a temperature interval at which microbes are easy to breed, and therefore, the growth of the microbes is maximumly restrained, the original flavor of products is maintained, and the products are convenient to eat. The preparation method comprises the following steps: cooking raw dumplings by using water with a temperature of 90-120 DEG C until the center temperature of the raw dumplings reaches over 80 DEG C, and carrying out steamed cooking on the dumplings; carrying out cooling on the cooked dumplings subjected to the steamed cooking in a vacuum cooling mode, wherein the temperature of a vacuum cooling chamber is maintained to be at 0-5 DEG C; when the temperature of cooked dumpling products is reduced to be at 0-4 DEG C, carrying out the quick-freezing on the cooked dumpling products for 30-40 min at a temperature of minus 30-minus 20 DEG C, so as to obtain the cooked dumpling products; and storing the obtained cooked dumpling products at a temperature of minus 18 DEG C. The obtained cooked dumpling products can be eaten through microwave heating, and therefore, the obtained cooked dumpling products are convenient to eat, and adapt to the fast-paced life needs of moderns, so that novel edible dumplings are provided for people.

Owner:TIANJIN UNIV OF COMMERCE

Production and storage method of quick-frozen green soy beans

InactiveCN104365819AAvoid cloggingFruits/vegetable preservation by freezing/coolingEvaporationHigh pressure

The invention relates to a production and storage method of quick-frozen green soy beans, belonging to the technical field of food processing. The method comprises the following steps of soaking, blanching, quick-freezing and storing. According to the production and storage method of quick-frozen green soy beans, water is atomized by using a high-pressure dry fog machine to form small particles with the particle sizes of smaller than 10 microns to ensure that water mist can be evaporated within extremely short time after being sprayed out, so that the rather high humidity in a refrigeration house is maintained, furthermore, the evaporation speed of water on the surfaces of quick-frozen vegetables is reduced, and the quick-frozen vegetables can be kept fresh.

Owner:SUZHOU FULL FORTUNE FOOD CO LTD

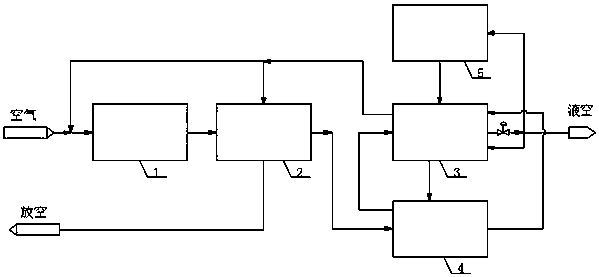

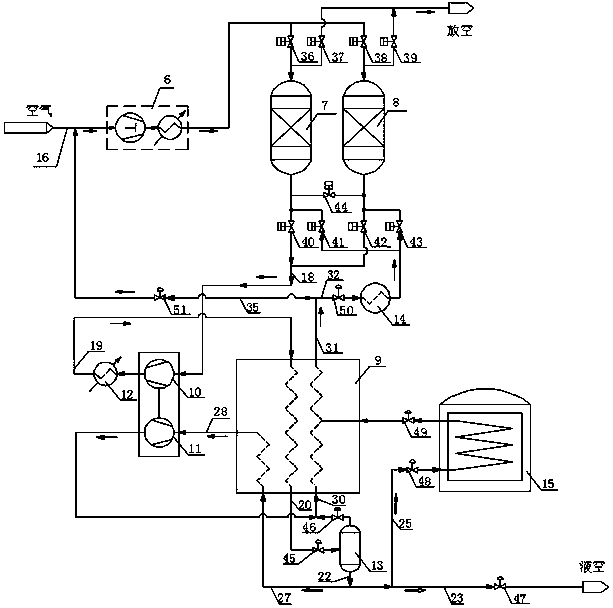

Technological system and technological method for performing cryogenic quick freezing on seafoods by air

PendingCN107736435ALow costReduce manufacturing costFood processingClimate change adaptationAir compressorMoisture

The invention provides a technological system and a technological method for performing cryogenic quick freezing on seafoods by air. The technological system comprises an air compressor, an adsorptionsystem, a switch valve, a throttling valve, an expansion turbine, a cooler, a cryogenic heat exchanger, a gas-liquid separator, a storing tank, a seafood cryogenic quick freezing box and a heater, wherein the technological method comprises the following steps of compressing the air; then removing impurities including moisture, carbon dioxide and the like in the air, and finally compressing and cooling the air to obtain liquid air to perform cryogenic quick freezing on the seafoods. According to the technological system and the technological method disclosed by the invention, air is used to replace liquid nitrogen, so that the cryogenic quick freezing cost of the seafoods is reduced, and the situation that lives are damaged and properties are damaged caused by leakage of the liquid nitrogen is avoided.

Owner:HANGZHOU HONGSHENG ZHONGHONG NEW ENERGY CO LTD

Production and storage method of quick-frozen mung beans

The invention relates to a production and storage method of quick-frozen mung beans, belonging to the technical field of food processing. The method comprises the following steps of soaking, blanching, quick-freezing and storing. According to the production and storage method of quick-frozen mung beans, water is atomized by using a high-pressure dry fog machine to form small particles with the particle sizes of smaller than 10 microns to ensure that water mist can be evaporated within extremely short time after being sprayed out, so that the rather high humidity in a refrigeration house is maintained, furthermore, the evaporation speed of water on the surfaces of quick-frozen vegetables is reduced, and the quick-frozen vegetables can be kept fresh.

Owner:SUZHOU FULL FORTUNE FOOD CO LTD

Freezing and fresh-keeping method for meat products

InactiveCN104938607AEasy to keep freshReduce spoilageFood processingMeat/fish preservation by freezing/coolingEngineeringCold storage

The invention discloses a freezing and fresh-keeping method for meat products, which comprises the steps of selecting meat products, freezing meat products, adjusting the temperature and the humidity of a cold reservoir, venting the cold reservoir, and the like. According to the invention, after meat products are selected and cleaned, meat products are rapidly precooled. Therefore, the quick-frozen load of the cold reservoir is reduced and the fresh-keeping effect of meat products is improved. Meanwhile, the energy is saved at the same time. Meanwhile, through the cooperation of an additionally added anti-staling agent and the ventilation process, the quality of meat products is effectively prevented from getting deteriorated or worse during the storage process. Therefore, meat products can be stored for a sufficient period of time.

Owner:TONGLING XINMENGXIANG AGRI & ANIMAL HUSBANDRY TECH CO LTD

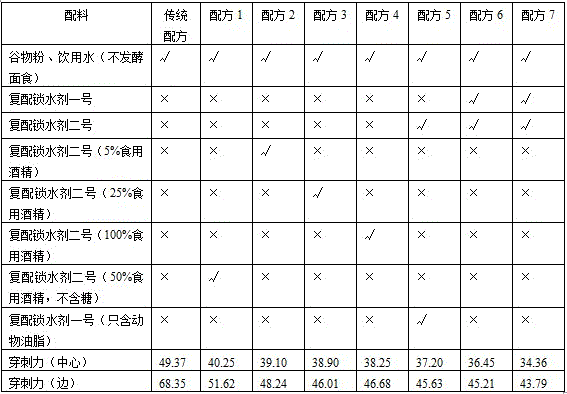

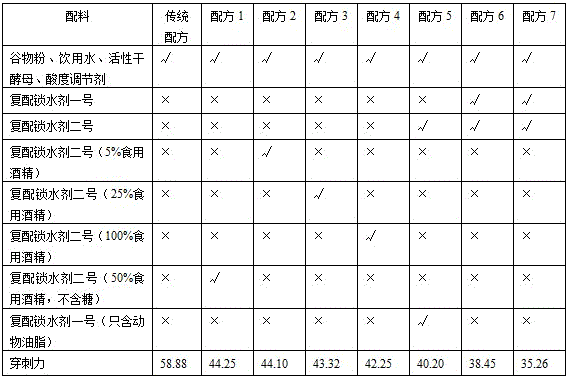

Quick-frozen steamed wheaten food suitable for microwave rewarming and production method thereof

PendingCN106071754AConvenient reheating methodWide sales channelsYeast food ingredientsFood preservationAlcoholMicrowave

The invention discloses a quick-frozen steamed wheaten food suitable for microwave rewarming and a production method thereof. The quick-frozen steamed wheaten food comprises the following raw materials: cereal powder and drinking water; the wheaten food contains a compound water-locking agent 2, and the compound water-locking agent 2 contains edible alcohol, wherein the concentration of the edible alcohol is 5-100%. The wheaten food comprises the following components in parts by weight: 100 parts of cereal powder, 50-60 parts of drinking water, and 0.02 parts of the compound water-locking agent 2. The wheaten food is suitable for microwave rewarming, the special water-locking agent is used, and the wheaten food has the following advantages that the quick-frozen Chinese-style steamed wheaten food is warmed for eating through a microwave rewarming mode, mouthfeel is loose, soft, and tasty; the novel convenient rewarming mode for the quick-frozen Chinese-style steamed wheaten food is increased, the novel types of the same kinds of products are added, and the wheaten food develops wider sale channels such as convenience stores, railway stations, and airports.

Owner:TIANJIN GOUBULI FOOD

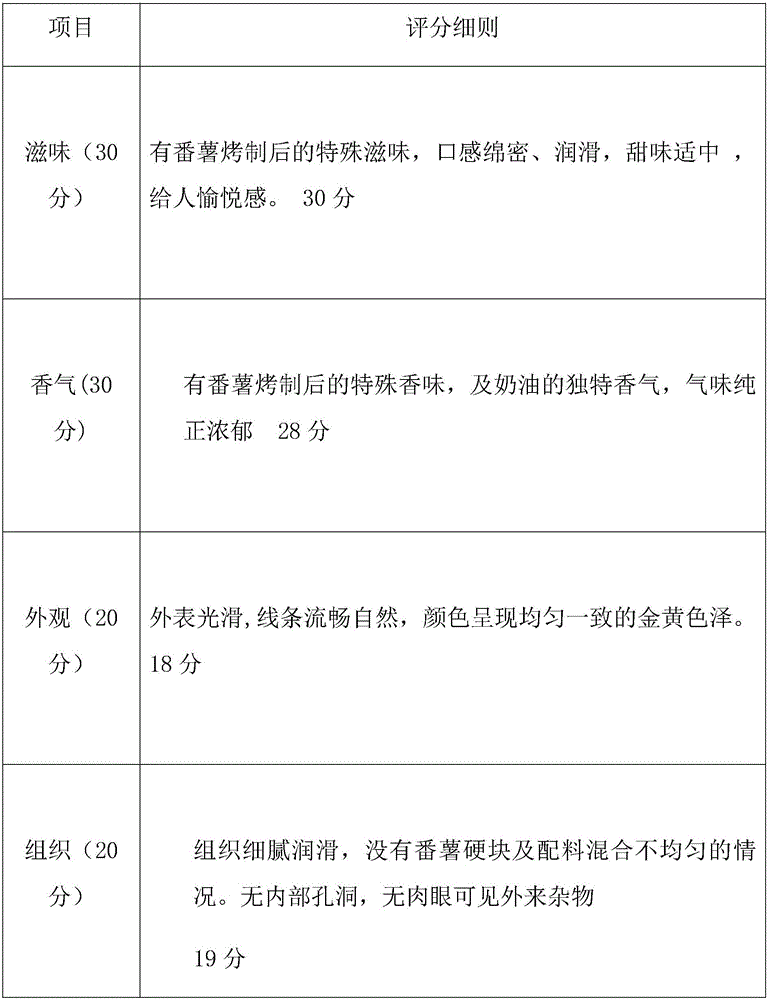

Quick-frozen roasted sweet potato manufacturing method

The invention provides quick-frozen roasted sweet potatoes. The quick-frozen roasted sweet potatoes are prepared by steps: step one, cleaning sweet potatoes and roasting; step two, taking out flesh of the roasted sweet potatoes, and trimming original skin of the sweet potatoes into a certain shape, and subjecting the flesh of the sweet potatoes to tunnel microwave high-temperature sterilization; step three, adopting a vacuum electric heating stirrer for well stirring the pulp of the sweet potatoes and ingredients under a vacuum heating condition, wherein the ingredients are mainly selected from one or more of milk powder, vegetable shortening, custard powder and white sugar; step four, subjecting products obtained at the step three to forming lamination, refilling mixed sweet tomato mash into a mould, starting a vacuum piston type forming machine, and laminating the trimmed sweet potato skin to surfaces of the formed products; step five, starting a vacuum pre-cooler for precooling the roasted sweet potatoes subjected to forming lamination; step six, putting the pre-cooled products into a quick-freeze storage; step seven, adopting a continuous pillow type packaging machine for quickly packaging to obtain products.

Owner:湖南非你魔薯食品股份有限公司

Production and storage method of quick-frozen peas

InactiveCN104365823AAvoid cloggingFruits/vegetable preservation by freezing/coolingEvaporationEngineering

The invention relates to a production and storage method of quick-frozen peas, belonging to the technical field of food processing. The method comprises the following steps of soaking, blanching, quick-freezing and storing. According to the production and storage method of quick-frozen peas, water is atomized by using a high-pressure dry fog machine to form small particles with the particle sizes of smaller than 10 microns to ensure that water mist can be evaporated within extremely short time after being sprayed out, so that the rather high humidity in a refrigeration house is maintained, furthermore, the evaporation speed of water on the surfaces of quick-frozen vegetables is reduced, and the quick-frozen vegetables can be kept fresh.

Owner:SUZHOU FULL FORTUNE FOOD CO LTD

Fluidized instant freezer and fluidized instant freezing method

PendingCN108981268ATightly boundImprove insulation effectLighting and heating apparatusStationary refrigeration devicesThermal insulationControl system

The invention discloses a fluidized instant freezer and a fluidized instant freezing method. The fluidized instant freezer comprises a frame, a thermal insulation storage chamber, a cleaning and blow-dry device, a material conveying system, a refrigerating system, a defrosting system and an electrical control system. The method includes steps of examination, starting and stopping. By combination of a fluidized instant freezer and a tunnel instant freezer, different freezing requirements of different products including vegetables, aquatic products, meats and the like can be met, and the fluidized instant freezer is real ideal novel multipurpose instant freezing equipment. An evaporator is changed from a horizontal mode into a vertical mode, and high freezing efficiency, short time, reasonability in air distribution and low energy consumption are realized; by combination of mechanical pulse and high-pressure airflow, high freezing quality and freeness of caking are realized; a one-stagespeed control mode of a material conveying belt is changed into two-stage respective speed regulation, so that great material freezing effects can be guaranteed, and material caking can be prevented.

Owner:宁夏天瑞产业集团现代农业有限公司

A kind of method for quality-preserving and evenly thawing quick-frozen side dishes

InactiveCN101715807BA balanced dietThere will be no mass reproductionFruit and vegetables preservationFood processingSide dishHorticulture

The invention relates to a method for preserving and evenly thawing fast-frozen side dishes, belonging to the technical field of the further processing of agricultural products. The method comprises the following main steps of: selecting fresh vegetables as raw materials, washing, cutting, blanching, color conserving, cooling, draining, matching, packing, fast-freezing, storing and micro-wave thawing. According to the method, vegetables with different nutrients, textures and colors are matched together and are good for health after being eaten; and different vegetables are cut in different sizes to improve the thawing effect, and the combined thawing of samples is carried out by three-segment dielectric heating. The invention has the advantages that by the segmented combined thawing of dielectric heating, the colors of thawed fast-frozen side dishes are similar to that of fresh vegetables, the nutrients of the side dishes are well kept, the thawing is carried out evenly, the textures of the vegetables are well kept, the thawing quality of the fast-frozen side dishes is improved, thereby achieving the characteristics of effectively reduced thawing time, good original shape after the thawing, low production cost, energy saving and the like.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

Vacuum freeze-drying technological method

InactiveCN105020988AIncrease diversityAvoid range increaseDrying solid materials without heatControl systemAdditive ingredient

The invention discloses a vacuum freeze-drying technological method. The vacuum freeze-drying technological method includes the following steps of quick freezing of materials, precooling of a drying bin, warehousing of the materials, vacuumizing, drying and material discharging. The vacuum freeze-drying technological method has the advantages that a drying machine mainly comprises a refrigerating system, a heating system, a vacuum system and a control system, and the four systems are used in cooperation to remove water in the materials in the whole material freeze-drying process. According to a temperature curve of the method, temperature is increased rapidly at first, is maintained and then is gradually decreased and maintained repeatedly, in this way, water in the frozen materials is evaporated rapidly at first, and then is released gradually and slowly; the nutritional ingredients and microelements of freeze-dried materials are almost the same with fresh materials, the color, flavor and smell are changeless, and the method is environmentally friendly. The range of materials capable of being dried is greatly enlarged by means of the method, the drying difficulty is reduced, and thus the diversity of food options is improved for people.

Owner:DANDONG JUNAO FOODSTUFF

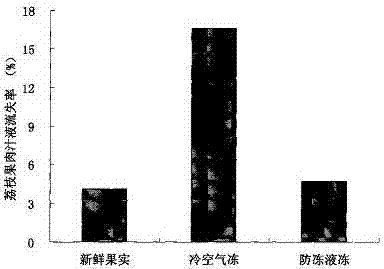

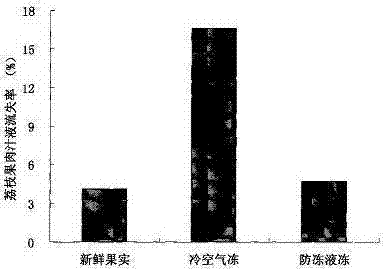

Methods for quickly freezing litchi by use of low-temperature antifreeze liquid

InactiveCN102475128AKeep the colorKeep shapeFruits/vegetable preservation by freezing/coolingPlastic filmComponents of crude oil

The invention belongs to the technical field of freezing processing of fruits, and relates to a method for quickly freezing litchi by use of low-temperature antifreeze liquid. The method comprises soaking litchi fruits in acid solution, wrapping and sealing with plastic film, and immersing in or spraying with low-temperature antifreeze liquid to quickly freeze. The product of the method as quick-frozen litchi fruits by use of antifreeze liquid is characterized in that the fruit hull is free of cracks, the fruits can retain the original appearance, nutrients and fresh fruit quality after thawing, and little pulp juice is lost. Compared with other methods for quickly freezing litchi fruits, the method of the invention is convenient, is high in product quality and low in energy consumption, and can save production cost by more than 20%.

Owner:DALIAN ZHAOYANG SOFTWARE TECH

Quick-freezing and cold storage method for fruits and vegetables

InactiveCN102475114AQuality improvementImprove preservation qualityFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingVitrificationGlass transition

The invention discloses a quick-freezing and cold storage method for fruits and vegetables, which includes the steps: preparing water-removing liquor, removing water, testing glass transition temperature, using a differential scanning calorimeter to measure glass transition temperature of fruits and vegetables subjected to water removal, quick freezing, ice-glazing the fruits and vegetables which are frozen quickly, cold-storing and the like. By using the method, quality of preservation of the fruits and vegetables is fine, and cold storage power consumption is reduced. Use of the water-removing liquor can effectively increase the glass transition temperature of the fruits and vegetables, so that the cold storage temperature is increased, cold storage power consumption is reduced, and energy can be saved by 10-15%. In addition, the fruits and vegetables subjected to water removal using the method are high in internal stability, internal chemical change and biochemical change are hindered, and the preservation quality is high.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Freeze-preservation method of fruits and vegetables

InactiveCN104957241AEasy to keep freshReduce spoilageFood processingFruits/vegetable preservation by freezing/coolingPreservation methodsPre cooling

The present invention discloses a freeze-preservation method of fruits and vegetables, which includes the following steps: selecting, washing, and freezing fruits and vegetables, and adjusting temperature and humidity of a cold storage, ventilating the cold storage, etc. The fruits and vegetables are rapidly pre-cooled after being selected and washed, which reduces the quick-freezing load of the cold storage, not only is beneficial for the preservation of the fruits and vegetables, but also saves energy; and at the same time, by combining ventilation, the deterioration or quality decline of the fruits and vegetables during storage can be effectively prevented, and therefore the fruits and vegetables can be stored for a long enough time.

Owner:TONGLING XINMENGXIANG AGRI & ANIMAL HUSBANDRY TECH CO LTD

Quick-freeze cold storage preservation method for marine products

InactiveCN105010497AStrong chelating abilityStop rotFood processingMeat/fish preservation by coatingQuick FreezeChlorine dioxide

The invention discloses a quick-freeze cold storage preservation method for marine products. The quick-freeze cold storage preservation method comprises the following steps that firstly, purchased sea products are sampled and quarantined, sorting is conducted after variety classification, and impurities and unqualified sea products are removed; secondly, the sea products are washed through clean water and soaked in salt water and pass through a hair machine after water is drained off, and the sea products are weighed and divided into plates according to ration requirements; thirdly, the sea products are placed into dipping liquid at the temperature of 15-20 DEG C, and after water is drained off, the sea products are cooled to 6-8 DEG C and placed into liquid chlorine dioxide for 3-5 minutes; fourthly, the peripheries of the sea products are coated with preservation colloidal particles, and the sea products are sent to a tunnel type liquid nitrogen quick freezing device to be frozen quickly; fifthly, the sea products are soaked into magnetic water at the temperature of 3-5 DEG C for 3-5 s, after water is drained off quickly, ice films are formed on the surfaces of the sea products, and the sea products are cooled to the temperature of minus 5 to minus 10 DEG C for 3-5 min and are sent to a refrigeration house with the temperature of minus 5 to minus 18 DEG C after being detected to be qualified. According to the quick-freeze cold storage preservation method, sterilization can be conducted instantaneously, efficiently and safely in a non-residual mode, and the method has the advantages that the quick freezing efficiency is high, and the energy consumption and electricity consumption are low.

Owner:BEIHAI SANHE SEAFOOD CO LTD

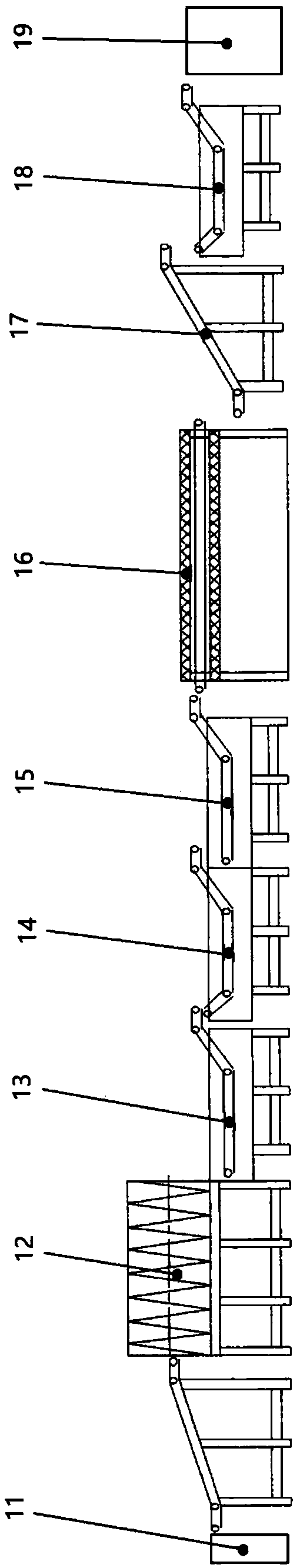

Fluidized quick-freezing production line and process of green leafy vegetables

InactiveCN109122819AInhibition of recovery rateGuaranteed qualityFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingQuick FreezePeroxidase

The invention discloses a fluidized quick-freezing production line of green leafy vegetables. The fluidized quick-freezing production line comprises a raw material picking station, a washing device, ablanching device, a vacuum cooling device, a fluidized quick freezing machine, a packing device, a metal detector and a refrigerator which are sequentially arranged along a production line body and connected with one another through a conveyor belt. The production line adopts a vacuum cooling mode, there is no need to prepare a large amount of cold water, a draining step is omitted, not only is the cooling efficiency high, the production energy consumption is reduced, but also the recovery rate of peroxidase can be effectively inhibited, the original quality of the green leafy vegetables is maintained, and the shelf life of the green leafy vegetables is prolonged. The invention also discloses a fluidized quick-freezing production process of the green leafy vegetables. The production process comprises the following steps of pretreatment of raw materials, washing, blanching sterilization, vacuum cooling, quick freezing in a fluid state, screening, packaging, detection and refrigeration.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com