Freeze-drying system

A drying system, vacuum freeze-drying technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of difficult storage, inconvenient transportation and carrying, difficult to guarantee the demand for liquid nitrogen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

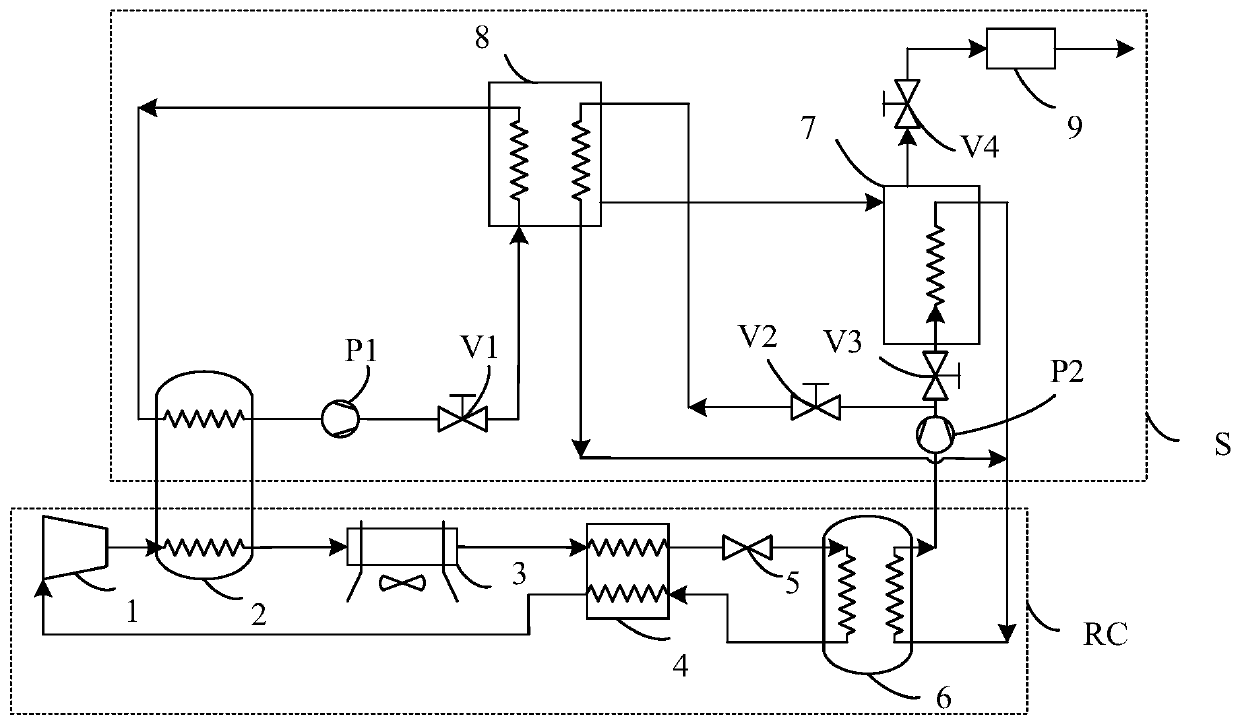

[0056] See figure 1 , Is a schematic structural diagram of a freeze-drying system provided by an embodiment of the present invention, including: a mechanical mixed working fluid cryogenic refrigeration unit (RC) and a vacuum freeze-drying unit (S); among them:

[0057] The mechanical mixed refrigerant cryogenic refrigeration unit (RC) includes: a compressor (1), a heat accumulator (2), an air-cooled condenser (3), a heat recovery heat exchanger (4), and a throttle valve ( 5) and a low-temperature cold accumulator (6), the outlet of the compressor (1) is connected to the inlet of the heat accumulator (2), and the outlet of the heat accumulator (2) is connected to the air-cooled condenser ( 3), the outlet of the air-cooled condenser (3) is connected to the high pressure inlet of the regenerative heat exchanger (4), and the high pressure outlet of the regenerative heat exchanger (4) is connected to the throttle valve The inlet of (5), the outlet of the throttle valve (5) is connecte...

Embodiment 2

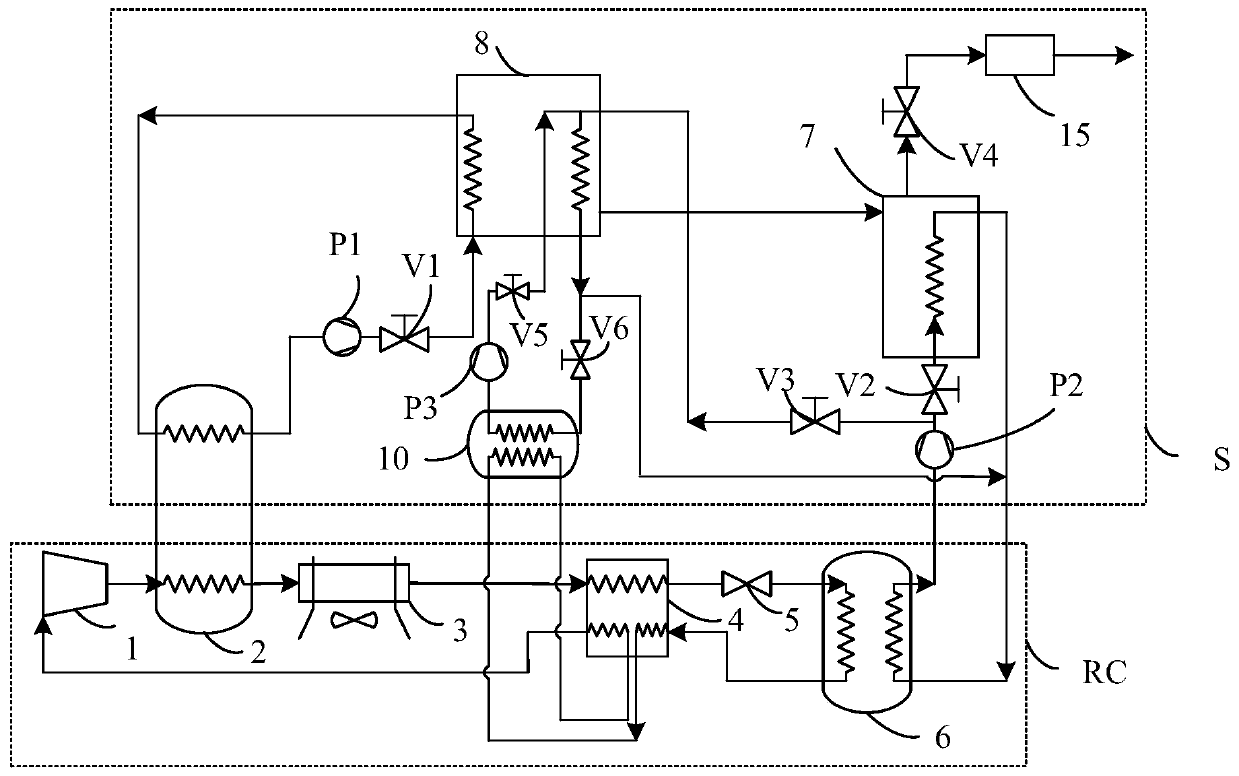

[0076] See figure 2 , Is a schematic structural diagram of the freeze-drying system provided in Example 2 of the present invention. The difference between the freeze-drying system provided in Example 1 is that the freeze-drying system provided in Example 2 of the present invention also includes a medium-temperature cold storage device (10), a medium-temperature Carrier refrigerant circulating pump (P3), the first medium temperature flow control valve (V5) and the second medium temperature flow control valve (V6);

[0077] The medium temperature refrigerant carrier outlet of the medium temperature cold storage device (10) is connected to the inlet of the medium temperature refrigerant carrier circulating pump (P3), and the outlet of the medium temperature refrigerant carrier pump (P3) is connected to the first medium temperature flow control The inlet of the valve (V5), the outlet of the first medium temperature flow control valve (V5) is connected to the low-temperature refrigera...

Embodiment 3

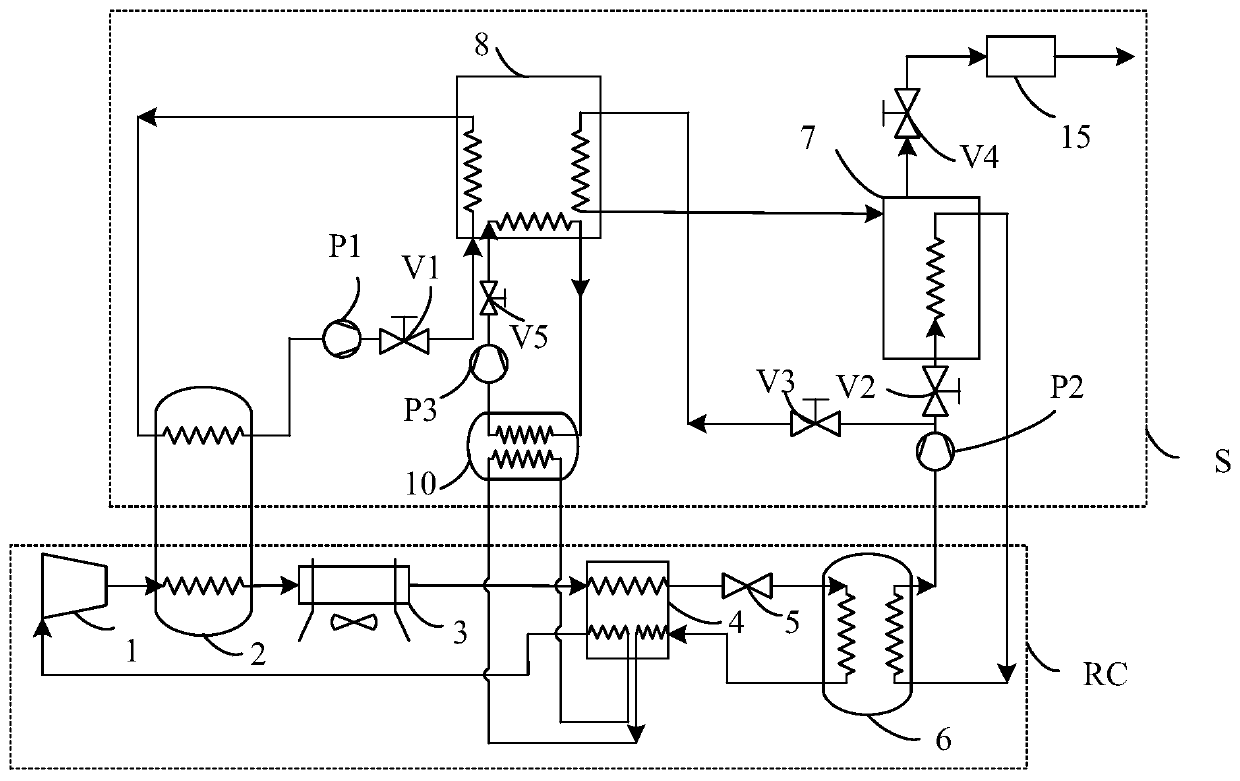

[0086] See image 3 , Is a schematic structural diagram of the freeze-drying system provided in Example 3 of the present invention. The difference from the freeze-drying system provided in Example 1 is that the freeze-drying system provided in Example 3 of the present invention also includes a medium temperature cold storage device (10), a medium temperature Carrier refrigerant circulating pump (P3) and the first medium temperature flow control valve (V5);

[0087] The medium temperature refrigerant carrier outlet of the medium temperature cold storage device (10) is connected to the inlet of the medium temperature refrigerant carrier circulating pump (P3), and the outlet of the medium temperature refrigerant carrier pump (P3) is connected to the first medium temperature flow control The inlet of the valve (V5), the outlet of the first medium temperature flow control valve (V5) is connected to the medium temperature refrigerant inlet of the drying chamber (8), and the medium temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com