Fluidized instant freezer and fluidized instant freezing method

A fluidized, quick-freezing machine technology, applied in coolers, lighting and heating equipment, refrigeration rooms, etc., can solve the problems of speed regulation, inability to meet, and low air circulation utilization in the case of inability to cool, so as to shorten the freezing time, The effect of reducing failure rate and high freezing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

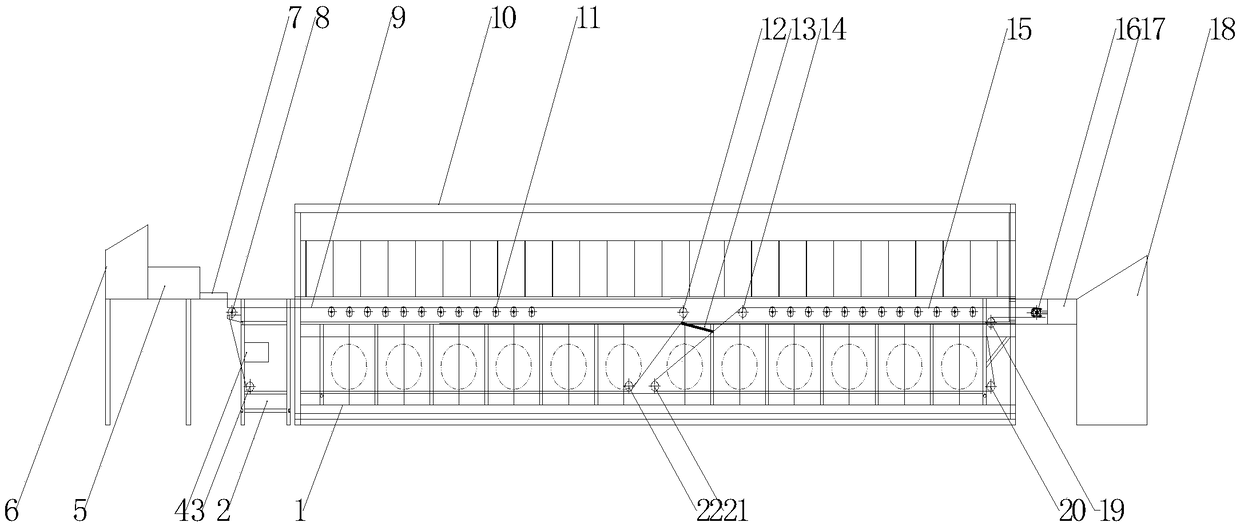

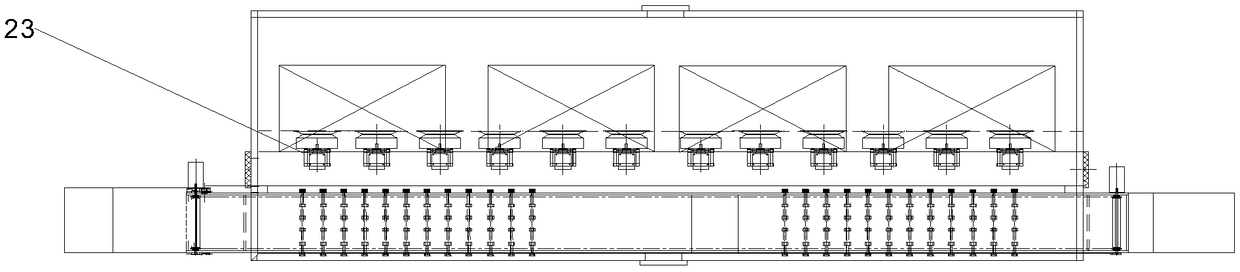

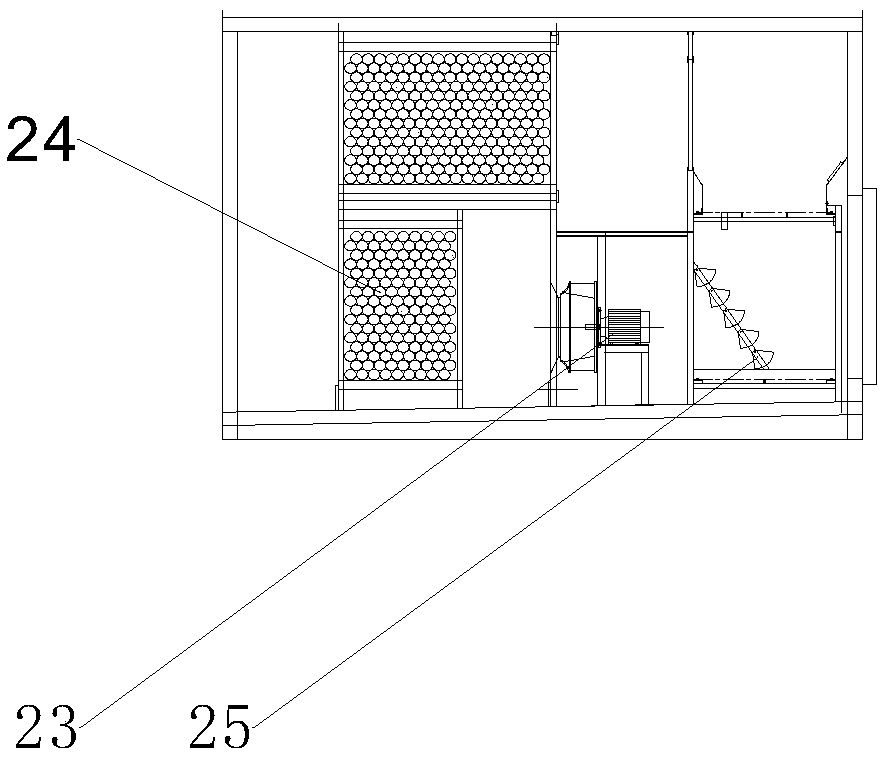

[0041] see Figure 1-3 , a fluidized quick-freezing machine, including a frame 1, a thermal insulation storage body 10, a cleaning and drying device, a material delivery system, a refrigeration system, a frosting system and an electrical control system.

[0042] The frame 1 main body is arranged in the heat preservation storehouse body 10, and its left and right ends respectively protrude from the heat preservation storehouse body 10 inlet and outlet, and the left and right ends of the frame 1 are all provided with temperature sensors (not shown in the accompanying drawings due to the angle of view). ).

[0043] The thermal insulation storage body 10 includes inner and outer stainless steel plate layers and a polyurethane thermal insulation layer in the middle, wherein the thickness of the stainless steel plate layer is 2.3mm, and the thickness of the polyurethane thermal insulation layer is 20cm.

[0044] The material conveying device includes 9 drive rollers installed on th...

Embodiment 2

[0056] A kind of fluidized quick-freezing method, this method is applied to a kind of fluidized quick-freezing machine in embodiment 1, and this method comprises:

[0057] When the fluidized quick-freezing machine is first started after installation, in order to prevent damage to the conveyor belt due to improper installation or adjustment, it is necessary to conduct a low-speed test run after a comprehensive inspection of the device.

[0058] Before starting, it is necessary to check whether there are foreign objects on the conveyor belt, especially the lower conveyor belt. When the temperature inside the heat preservation storehouse 10 is below -15°C, the transmission system must not be started immediately. Before starting, the ice and other sundries on the components of the transmission system must be checked and removed to prevent foreign matter from entering the transmission mechanisms and causing damage.

[0059] Before starting, you should also confirm whether the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com