Bidirectional-folding sextuple-pipe-wall reinforced radiating pipe

A heat dissipation pipe and reinforced technology, which is applied in the field of bidirectionally folded six-layer pipe wall reinforced heat dissipation pipes, can solve the problems of low heat dissipation efficiency, poor corrosion resistance, low system pressure, etc., and achieve improved heat dissipation efficiency and corrosion resistance. , the effect of improving the heat dissipation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

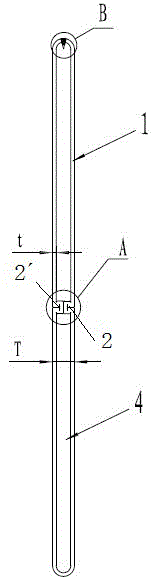

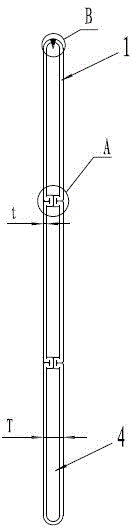

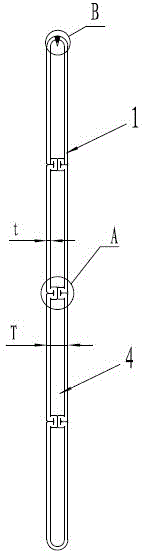

[0012] The invention relates to a heat dissipation pipe for a radiator with a new structure, which is a heat dissipation pipe with two pipe holes or multiple pipe holes welded by high frequency, which is formed by high frequency welding after forming aluminum foil materials. from figure 1 One of the embodiments of the invention shown, Figure 4 Partial schematic diagram at mark A, Figure 5 It can be seen from the local schematic diagram at the mark B that the tube walls 1 on both sides of the heat pipe have an inwardly recessed reinforcing rib 2, 2' along the length direction of the heat pipe, and the reinforcing ribs 2, 2' are from the tube wall 1 on each side to There are eight continuous bendings inside, and the eight bendings form a triple folded transverse folded layer in which the materials of each layer are tightly bonded in the thickness direction of the heat pipe. The top of the transversely folded layer has end planes 3, 3', and the end planes 3, 3' of the transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com