Method for controlling feed production online by means of near-infrared technology

A near-infrared and near-infrared spectrum technology, applied in the field of feed production control using near-infrared technology, can solve the problems of long test period, low work efficiency, limited detection of feed raw material quality indicators, etc., to ensure standardized production, improve production efficiency, The effect of guaranteeing product quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

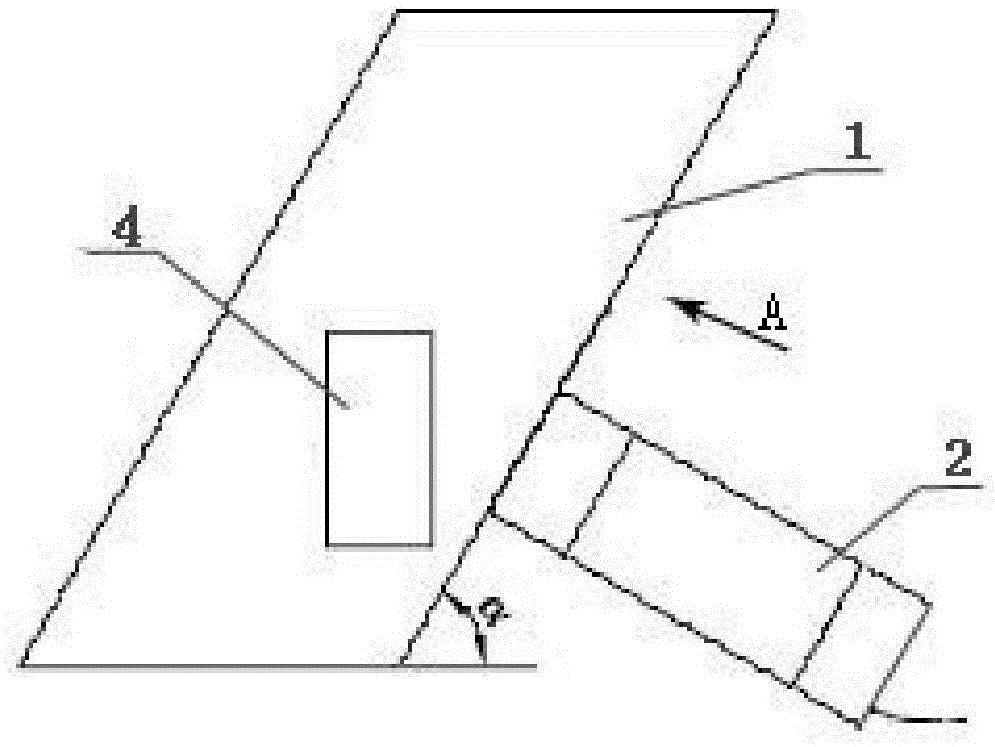

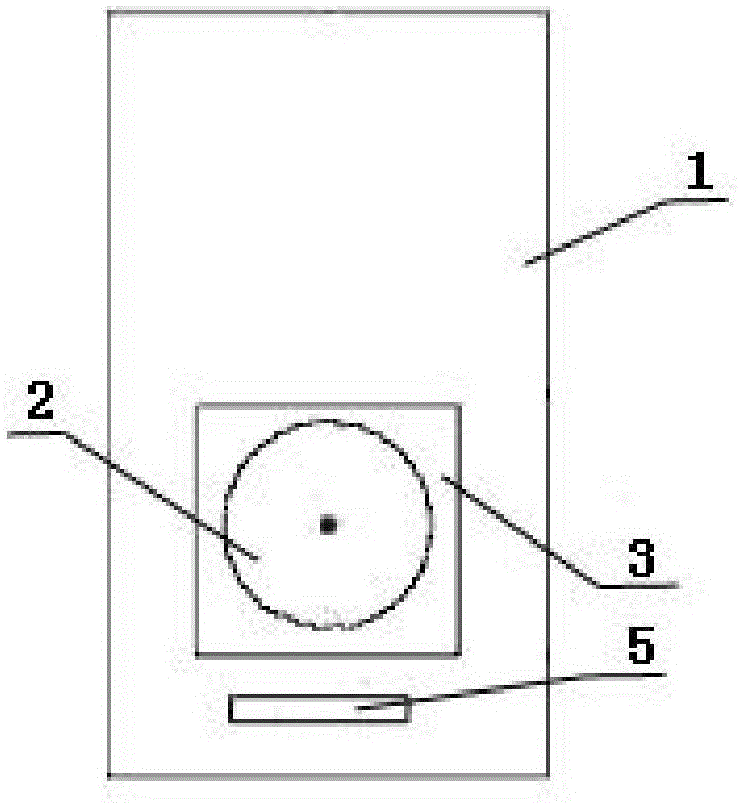

[0023] Introduce in detail below in conjunction with accompanying drawing the method for utilizing near-infrared technology online control feed production of the present invention, it comprises installing near-infrared probe on the feeding hopper of feed production line; Near-infrared spectrum information of raw material components and content information of nutritional components; nutritional components include conventional chemical indicators such as moisture, total energy, crude protein, crude fiber, crude fat, NDF, ADF, crude ash, calcium, phosphorus and starch, etc.; Including effective nutrient content such as digestible metabolic energy and digestible amino acids, etc.; the near-infrared spectrometer transmits the above-mentioned detected information to the computer equipped with the formula system; the computer compares the information transmitted by the spectrometer with the information in the formula system and then judges the feed raw The quality of the feedstuffs is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com