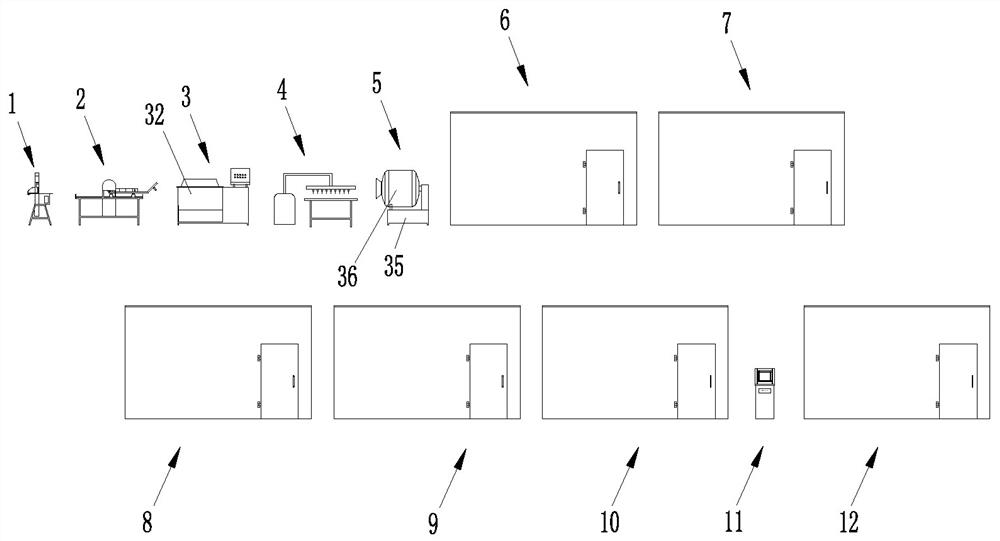

Quantitative stewed meat production process and production line

A production process and production line technology, applied in the field of quantitative braised meat production process and production line, can solve the problems of inconsistent maturity time, difficult to achieve product standardization and stable replication production, and high risk of deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

[0028] A quantitative stewed meat production process, comprising the following production steps:

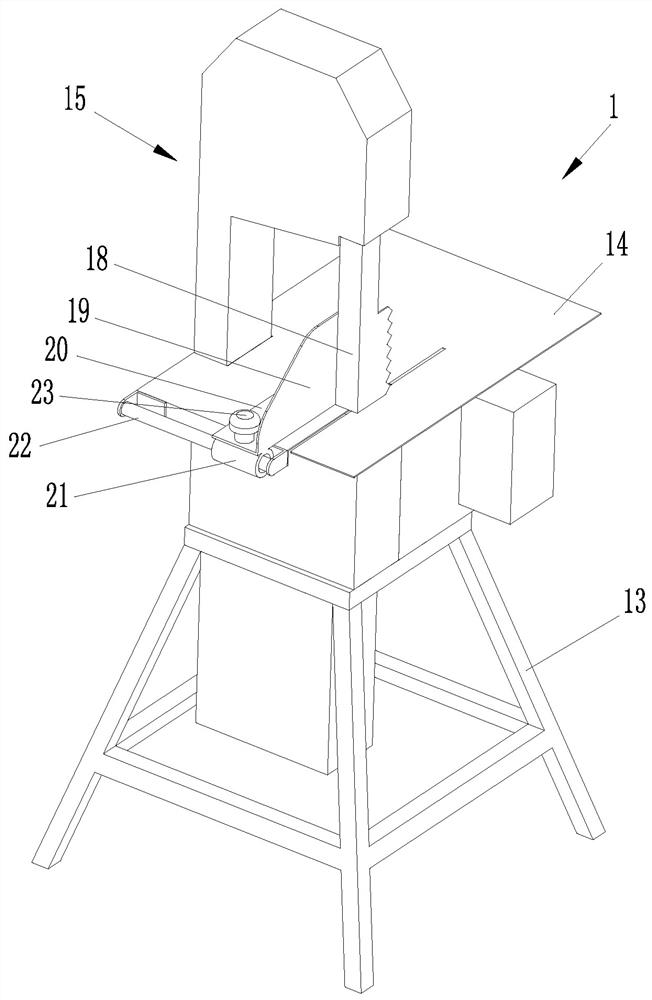

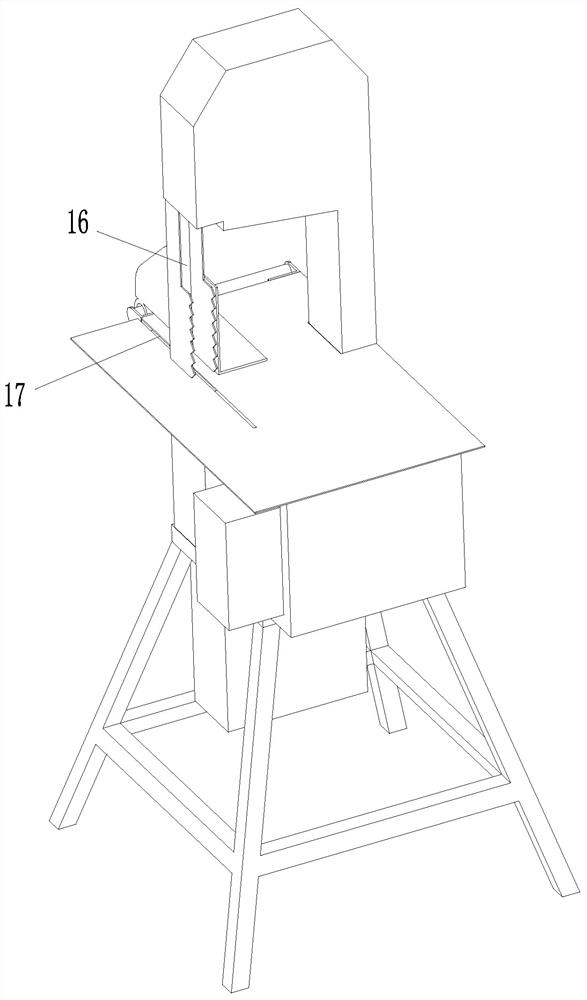

[0029] (1) Raw material division.

[0030] (2) De-blooded water is thawed to remove peculiar smell, and the water temperature is 85~95°C.

[0031] (3) Inject spice liquid.

[0032] The spice liquid formula for injection includes the following raw materials in parts by weight: 1000 parts of raw meat, 400 parts of spice water, 20 parts of table salt, 20 parts of monosodium glutamate, 10 parts of chicken essence, 60 parts of glucose, 2 parts of TG enzyme, 0.15 parts of sodium nitrite, 0.5 parts of sodium deoxyacetate, 10 parts of white wine. The weight error of each of the above raw materials is ±5%.

[0033] The spice water formula includes the following raw materials in parts by weight: 1000 parts of water, 5 parts of star anise, 3 parts of cinnamon, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com