Micropore reaction cup stacking device and using method thereof

A cuvette and microwell technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of huge conveying tracks, awkward movement of microwell plates, affecting the performance of unused microwells, etc. The effect of small space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

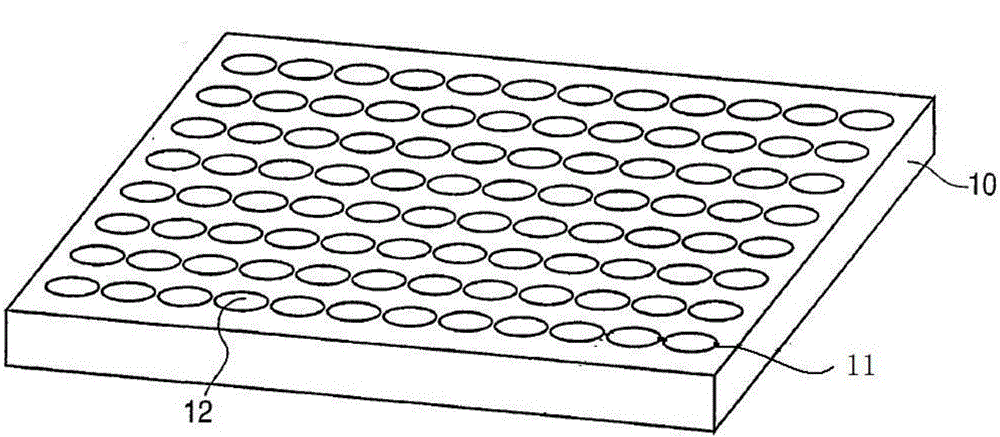

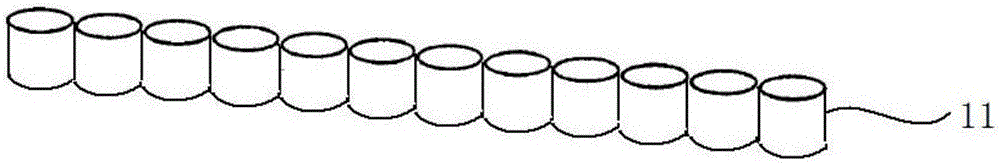

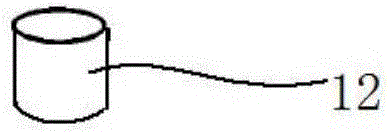

[0033] Such as Figure 5 As shown, the present invention provides a stacking device for microporous cuvettes, which includes a through bullet-clamp pipe 13 , and a plurality of microporous cuvettes 12 are stacked in the bullet-clip pipe 13 . The micropore cuvette 12 is a single micropore cuvette cut from the strip 11 of the micropore plate, and the micropore cuvette 12 can be transparent or opaque, see Figure 1-Figure 3 . Bullet clip type pipeline 13 is provided with the inlet and outlet of microporous cuvette 12, and the diameter of bullet clip type pipeline 13 is slightly larger than the diameter of microporous cuvette 12, guarantees that when stacking microporous cuvette 12 in bullet clip type pipeline 13, The hole cuvette 12 will not automatically fall off from the outlet of the bullet-clip pipeline 13 . Such as Figure 6 As shown, the device also includes a push rod 14, and the push rod 14 pushes the microporous cuvette 12 at the entrance of the bullet clip type pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com