Vacuum treatment method for multi-beam cathode assembly

A cathode component and vacuum treatment technology, which is applied in the manufacture of cold cathodes, thermionic cathodes, electrical components, etc., can solve the problems of unstable emission current and large influence of the vacuum degree of the whole tube on the amount of outgassing, and achieve good emission performance uniformity , long storage period, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

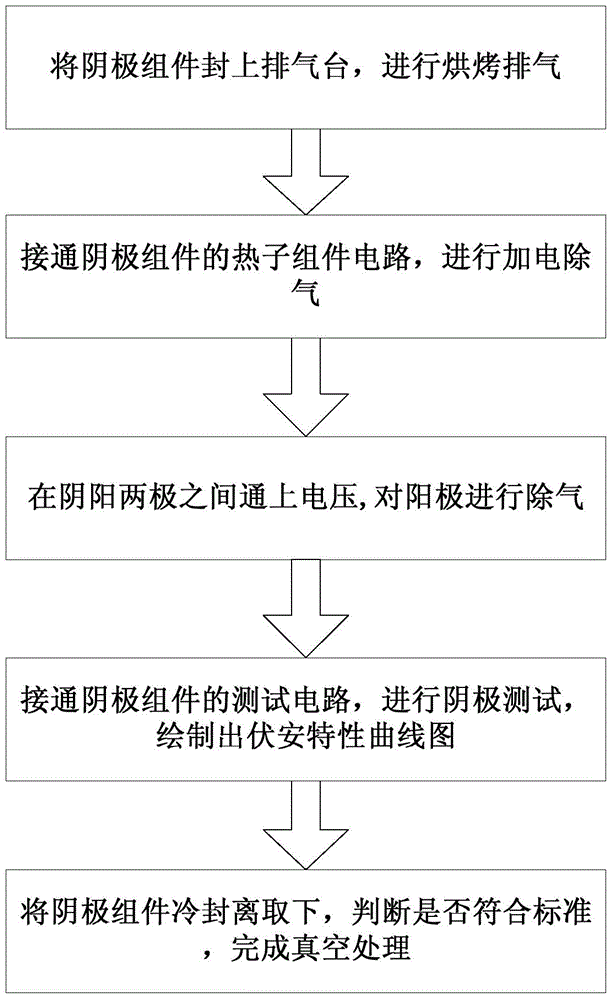

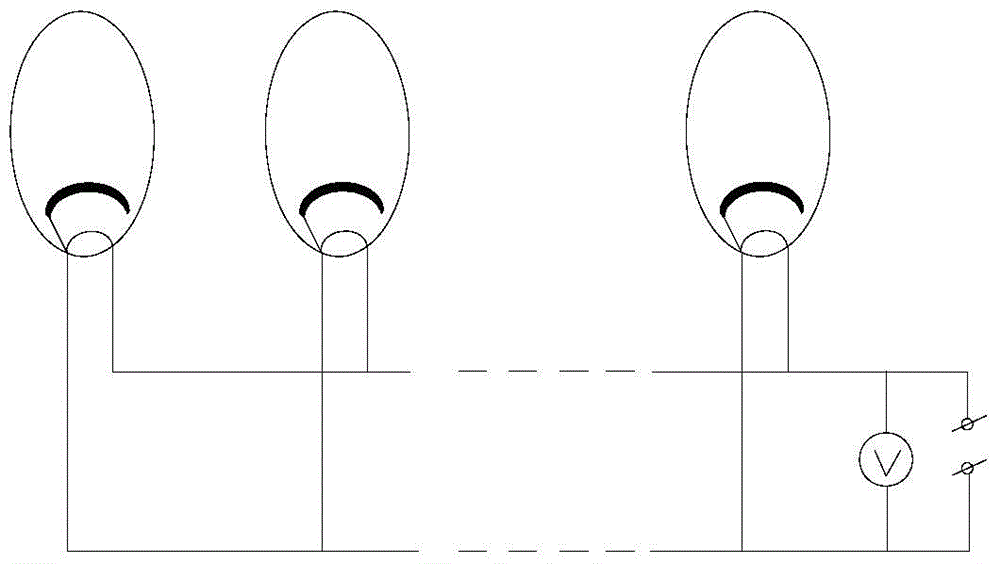

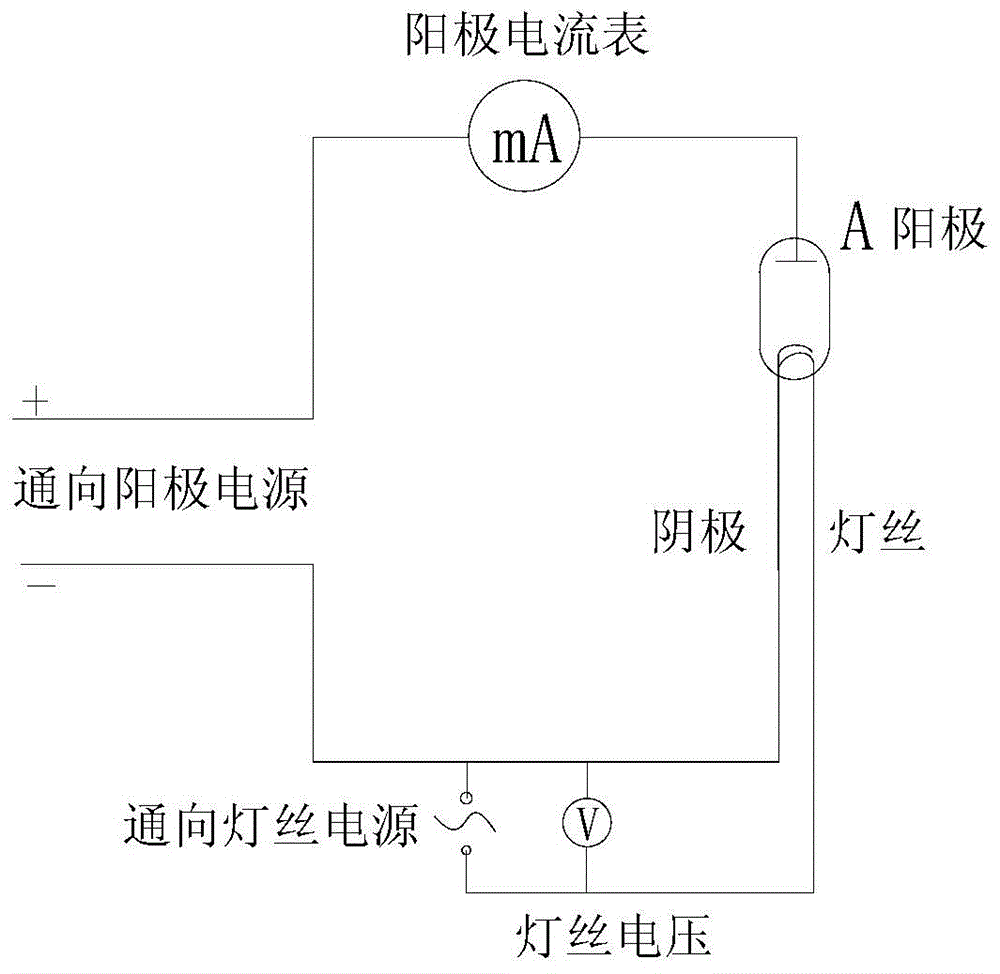

[0043] In the vacuum treatment method of the cathode assembly of the present invention, firstly, the cathode assembly is baked and exhausted, and the water vapor adsorbed on the inner and outer surfaces of the packaged glass tube is removed, and then the cathode assembly is energized and degassed, and the gas and gas adsorbed on the cathode are sucked away. Impurities, degas the installed anode, apply DC voltage between the cathode and anode to degas the anode, measure the cathode emission current under different pulse anode high voltages under different power of the thermal subassembly, and draw the volt-ampere characteristic curve , and finally the cathode assembly is vacuum-sealed to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com