Constant voltage output pulsed power supply with duty ratio adjustable range being 20%-80%

A technology of constant voltage output and pulse power supply, which is applied in the field of switching power supply, can solve problems affecting production efficiency and achieve the effect of improving production efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

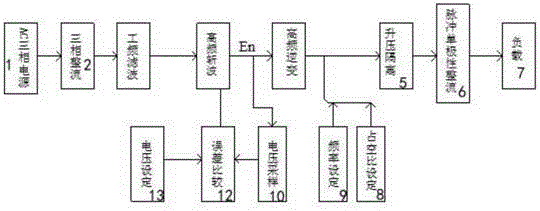

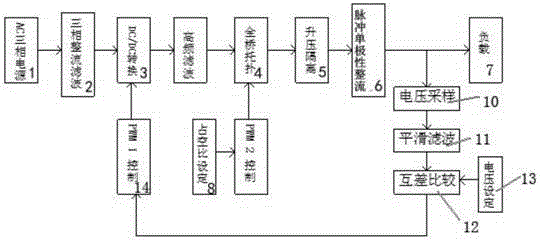

[0015] See figure 1 and figure 2 As shown, a constant voltage output pulse power supply with an adjustable duty ratio ranging from 20% to 80%, including an AC three-phase power supply 1, a three-phase rectification filter circuit 2, a DC / DC conversion circuit 3, a full bridge topology circuit 4, Boost isolation circuit 5, pulse unipolar rectification 6, the control signal output end of the AC three-phase power supply 1 is connected to the control signal input end of the three-phase rectification filter circuit 2, the control signal of the three-phase rectification filter circuit 2 The output terminal is connected to the input terminal of the DC / DC conversion circuit 3, and a full-bridge topology circuit 4 is connected between the DC / DC conversion circuit 3 and the boost isolation circuit 5, and the control signal output terminal of the boost isolation circuit 5 It is connected to the control signal input end of the pulse unipolar rectification 6 , and the control signal outp...

Embodiment 2

[0017] See figure 1 Shown is the unipolar pulse bias power supply of USER model BR-30A, which samples the DC voltage En after the DC / DC conversion circuit 3 and feeds it back to the mutual difference comparator 12 to compare and convert with the external set voltage. Form a series of unequal width pulse signals to control the opening and closing of the full-bridge switch tube to achieve the purpose of constant voltage. Its constant voltage is the DC voltage En after the constant DC / DC conversion circuit 3, not the voltage at the output terminal, because In this way, when the duty cycle of the output pulse is adjusted, the output power will change accordingly, and the smaller the duty cycle, the smaller the output power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com