Automatic dirt-removing method for indoor rectangular culture pond utilizing circulating water

A technology for recirculating aquaculture and breeding ponds, applied in fish farming, application, animal husbandry, etc., can solve the problems of excessive sediment, laborious, time-consuming, etc., and achieve the effect of reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

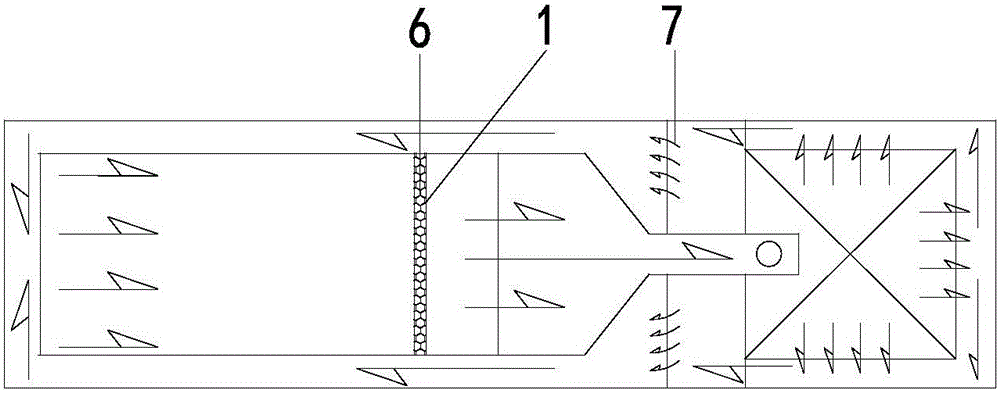

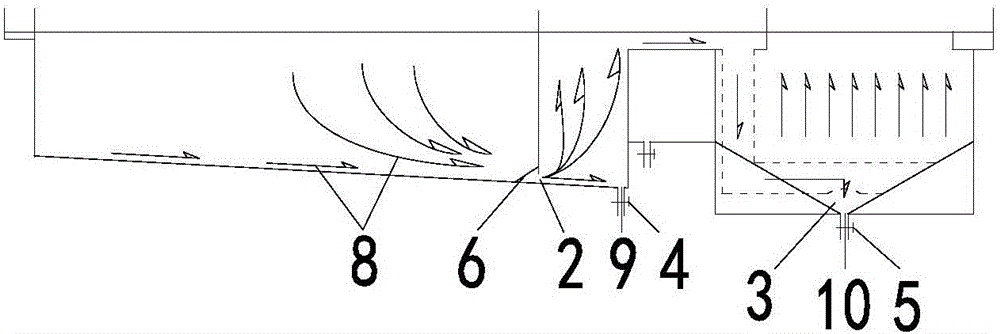

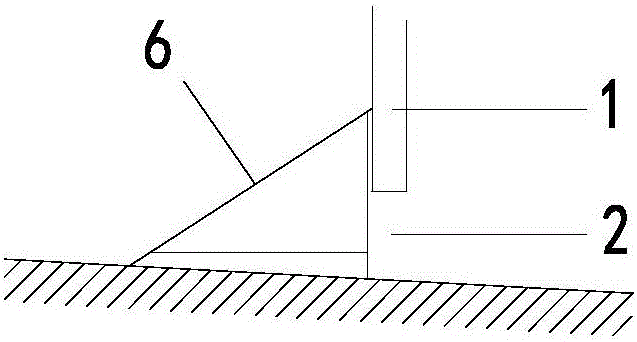

[0010] The structure and automatic cleaning mechanism of the present invention (see the accompanying drawings) are as follows: adopting baffle 1, baffle 1 and the gap between the bottom of the pool 2, the conical sewage collection tank 3, the sewage valve 4 and 5 and the inclined fence 6 composed of aquaculture The bottom of the pond is inclined to the side of the water outlet, the inclination is not less than 2%, the sewage pipe 9 and the sewage valve 4 are installed at the lowest position of the pond bottom, and a baffle 1 is installed at the water outlet end of the breeding pond 50cm from the edge of the pond; the upper side of the baffle 1 It is the same height as the breeding pond, and the left and right sides are fixed to the wall of the breeding pond, and there is a gap between the bottom and the bottom of the pond 2; on the side of the breeding pond in the breeding pond, a diagonal net 6 is installed at the lower end of the baffle and the bottom of the pond to block the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com