Processing method of raw octopus conditioning food

A technology for food conditioning and processing methods, applied in the direction of food science, etc., can solve the problems of low added value, insecure eating safety of raw octopus, single flavor, etc., and achieve good social and economic benefits, unique flavor and taste, high The effect of food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

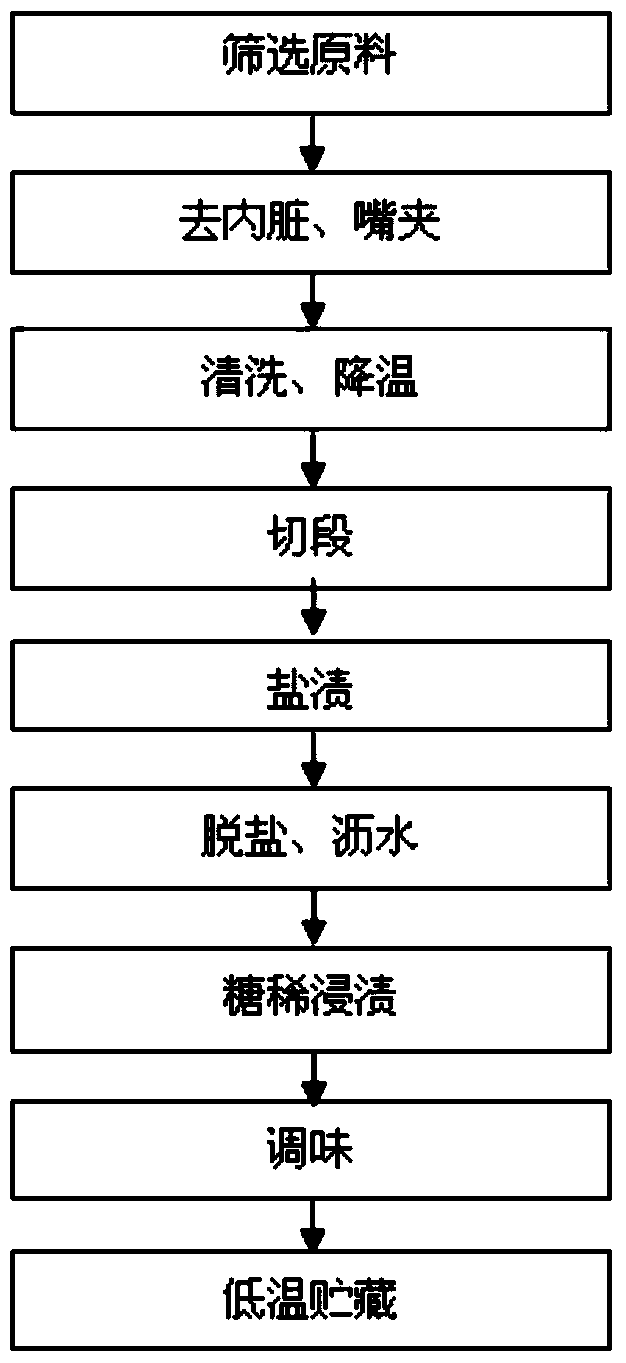

Image

Examples

Embodiment 1

[0027] Embodiment 1, the processing method of raw octopus conditioning food, carry out following steps successively:

[0028] 1), first screen the octopus as raw material, select fresh octopus, remove the octopus with odor that is not suitable for processing, then wash the raw material with clean running water, turn the head of the octopus over, cut the belly of the octopus with scissors, and remove Cut off the internal organs, cut off the mouth clip, and then wash the octopus one by one with clean running water to remove the impurities adhering to the octopus, and then immerse in ice water for 20 minutes to cool down.

[0029] 2), the cleaned octopus obtained in step 1) is uniformly cut into 7 cm long octopus segments, fully stirred with the octopus segments and edible salt (addition amount is 15%), and salted for 2 hours.

[0030] Remarks: The added amount is 15%, that is, the weight ratio of edible salt to octopus segments is 15%.

[0031] 3) After the salting is finished,...

Embodiment 2

[0037] Embodiment 2, the processing method of raw food octopus conditioning food, carry out following steps successively:

[0038]1) Screen the octopus as the raw material, thaw the frozen octopus (center temperature -18°C) in running water, thaw to the thawed state, remove the octopus with odor that is not suitable for processing, and then wash the raw material with clean running water, Turn the head of the octopus over, cut the abdomen of the octopus with scissors, remove the viscera, cut off the mouth clip, and then wash the octopus one by one with clean running water to wash away the impurities adhering to the octopus, and then soak it in ice water for 15 minutes. Realize cooling down.

[0039] 2), afterwards, uniformly cut the cleaned octopus into 5 cm long octopus segments, fully stir the cut octopus segments with edible salt (addition amount is 15%), and salt for 1.5 hours.

[0040] 3) After the salting, pour out the salted octopus, wash and desalinize it with clean ru...

Embodiment 3

[0046] Embodiment 3, the processing method of raw octopus conditioning food, carry out following steps successively:

[0047] 1) Screen the octopus as the raw material, thaw the frozen octopus (center temperature -18°C) in running water, thaw to the thawed state, remove the octopus with odor that is not suitable for processing, and then wash the raw material with clean running water, Turn the head of the octopus over, cut the abdomen of the octopus with scissors, remove the viscera, cut off the mouth clip, and then wash the octopus one by one with clean running water to wash away the impurities adhering to the octopus, and then soak it in ice water for 10 minutes. Realize cooling down.

[0048] 2) Afterwards, the cleaned octopus body parts are cut into 5cm segments, and the octopus feet are cut into 7cm segments, and the cut octopus segments are fully stirred with edible salt (addition amount is 10%), and salted for 2 hours.

[0049] 3) After the salting, pour out the salted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com