Self-exhaust composite drip chamber assembly

A compound, self-exhausting technology, applied in the field of medical devices, can solve problems affecting the work efficiency of medical staff, patients with vascular air embolism, doctor-patient disputes, etc., to reduce doctor-patient disputes, reduce labor intensity, and eliminate potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

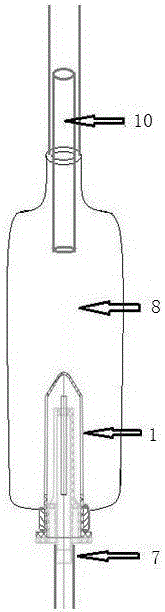

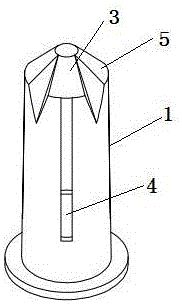

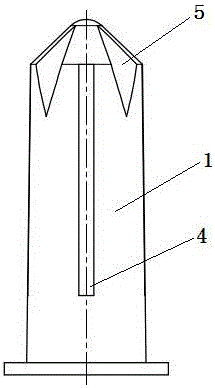

[0020] see Figure 1-6 , a self-exhausting composite drip funnel assembly, including an upper two-way 10, a drip funnel 8, and a lower two-way, wherein the lower two-way is a composite lower two-way, and the composite lower two-way includes a composite lower two-way outer sheath 1, Composite lower two-way inner core 2; wherein the composite lower two-way outer sheath 1 and the composite lower two-way inner core 2 are formed by separate injection molding, and the composite lower two-way outer sheath 1 and the composite lower two-way inner core 2 are bonded Connection, multiple exhaust water guide grooves 4 are opened on the wall of the compound lower two-way outer sheath 1, and multiple water diversion grooves 5 are opened on the top of the composite lower two-way outer sheath 1, and the exhaust water guide grooves 4 and the water diversion grooves 5 are staggered and corresponding The top of the composite lower two-way inner core 2 has an exhaust hole 6, and the periphery of t...

Embodiment 2

[0022] see Figure 1-6 , a self-exhausting composite drip funnel assembly, including the upper two-way 10, the drip funnel 8 and the lower two-way, wherein the lower two-way is a composite lower two-way, and the composite lower two-way includes a composite lower two-way outer sheath 1, a composite The lower two-way inner core 2, the composite lower two-way outer sheath 1 and the composite lower two-way inner core 2 are formed by integral injection molding, and the upper part of the integral injection molded part is covered with a water-conducting and diverging cap 3 by bonding; the composite lower two-way There are multiple exhaust water guide grooves 4 on the wall of the outer sheath 1, and the water diversion grooves 5 on the water diversion diversion cap 3 are staggered to correspond to the exhaust water guide grooves 4; the top of the composite lower two-way inner core 2 has an exhaust hole 6 , the periphery of the composite lower two-way inner core 2 also has a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com