Full-automatic assembly line battery grouping system based on quickly continuous detection

An assembly line, fully automatic technology, applied in the direction of secondary battery manufacturing, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of low assembly efficiency, large manual errors, complex and difficult control of the assembly process, etc., to achieve Improve the matching efficiency, eliminate the measurement time difference, and detect the effect of fast and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing:

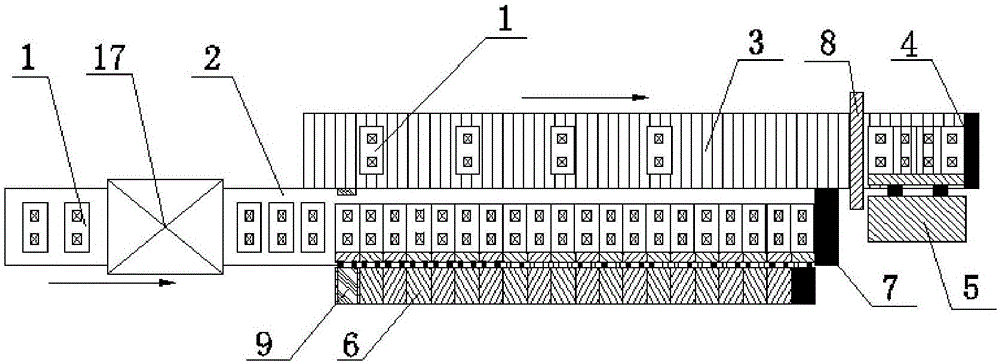

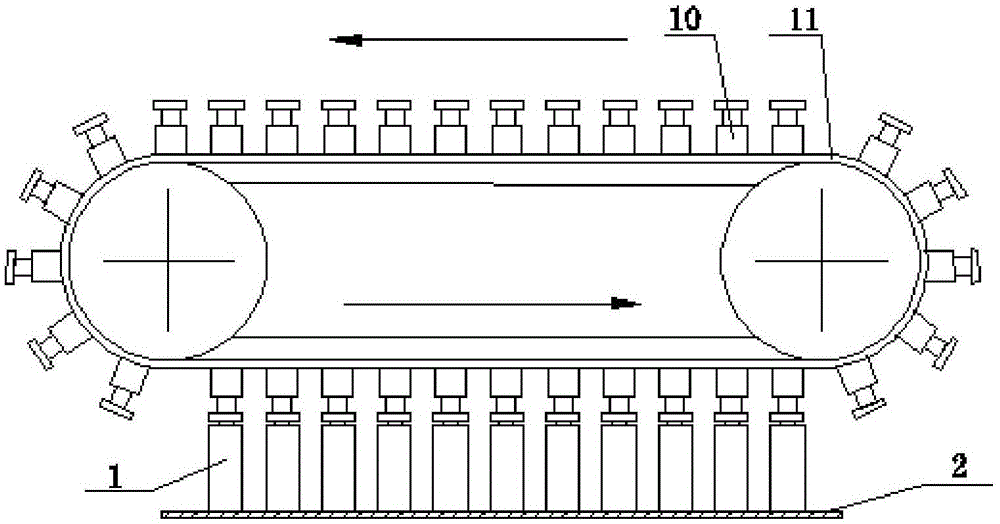

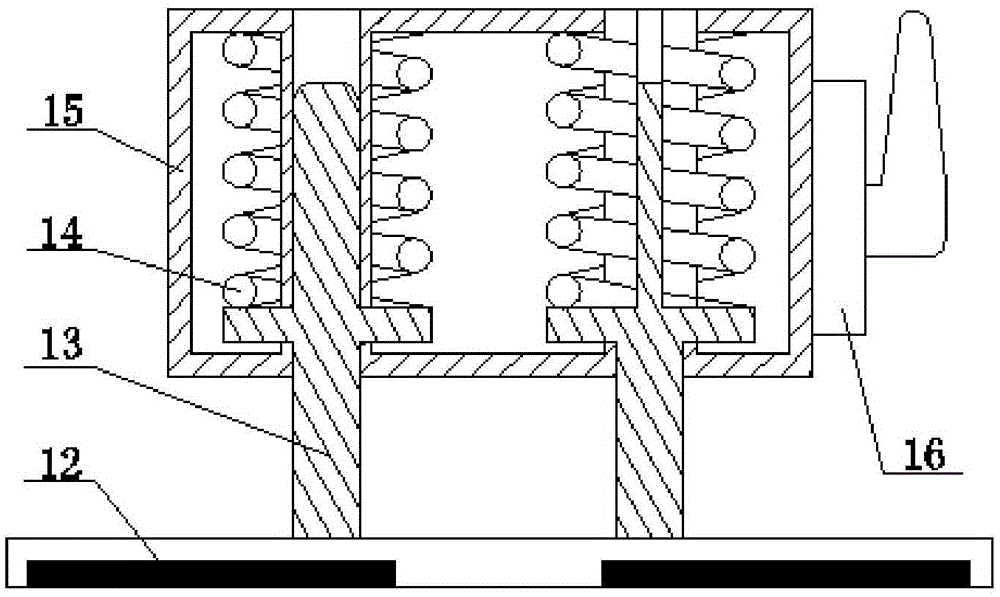

[0047] See attached figure 2 As shown, the battery detection part is mainly composed of a chain conveyor belt 11 and a detection probe 10, see attached image 3 , 4 As shown, the battery detection probe 10 is mainly supported by an outer shell 15, and two springs 14 are installed in the shell 15, and the springs 14 respectively pass through two push rods 13, one end of the spring 14 is fixed with the shell 15, and the other end is connected with the two push rods. Rod 13 is fixed, and two push rods 13 can move in the movement hole that leaves in shell 15, and the part that push rod 13 protrudes out of shell 15 is connected with a rectangular block with certain thickness, and two metal sheets 12 are inlaid on the rectangular block. When testing the battery, the push rod 13 is pushed by the pressure of the spring 14, and the push rod presses the two metal sheets 12 against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com