FDM3D printing achieving method, printing system and jet flow control method under space environment

A printing system, space environment technology, used in additive processing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

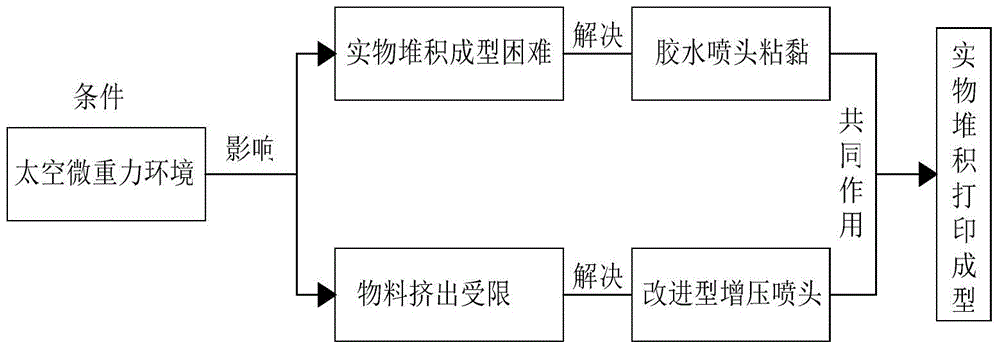

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

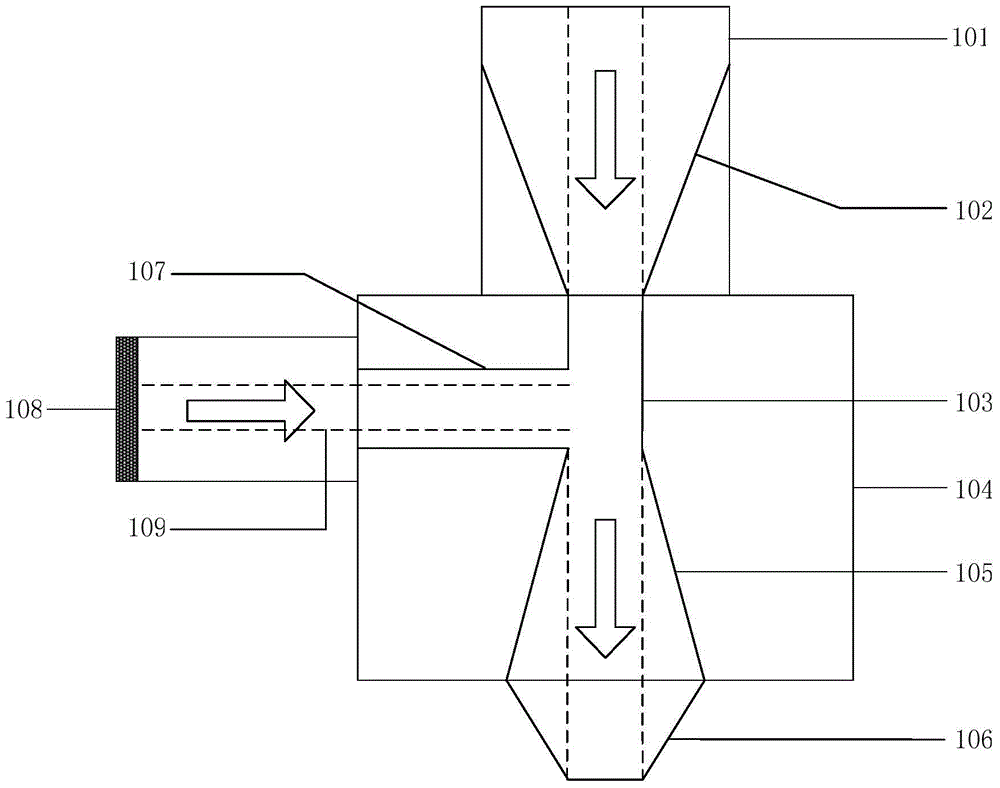

[0034] Such as figure 1 As shown, it is the front view of the 3D printing Venturi nozzle of the present invention; it includes a gas inlet 101, a conical constriction section 102, a cylindrical throat 103, a heating mechanism 104, a conical diffusion section 105, an extrusion outlet 106, and a feeding The pipeline 107, the inner channel 109 of the material delivery pipeline, and the shrinkage 108 of the material delivery pipeline. Among them, the pressurized gas enters from the inlet 101 and passes through the conical constriction section 102. At this time, the gas flowing at a high speed passes through the cylindrical throat 103. Adsorption takes place. The other end of the throat is connected to the feeding pipeline 107. When passing through the heating mechanism 104, the silk material in the channel 109 in the feeding pipeline will be formed into a molten state. When the low pressure cylindrical throat 103 is reached, it will be absorbed by the air along with the air. Mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com