High-strength super-toughness resin concrete and preparing method thereof

A technology of resin concrete and super-toughness, which is applied in the field of high-strength super-toughness resin concrete and its manufacturing, can solve the problems of not meeting the deformation performance requirements of long-span bridges, affecting the durability of concrete, and poor deformation capacity, etc., to achieve rapid construction technology Convenient, not easy to permanently deform, and reduce the effect of self-shrinkage

Active Publication Date: 2015-11-11

NANJING ROAD KEEPER TECH

View PDF2 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, domestic resin concrete is mostly used in repairing materials. The repairing construction technology vibrates the repaired area after pouring or grouting. Although the strength of the cured concrete is high, the deformation capacity is poor, which cannot meet the deformation performance requirements of long-span bridges. ; Furthermore, early self-shrinkage occurs in the curing of concrete, which leads to fracture and cracking of concrete, which seriously affects the durability of concrete

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

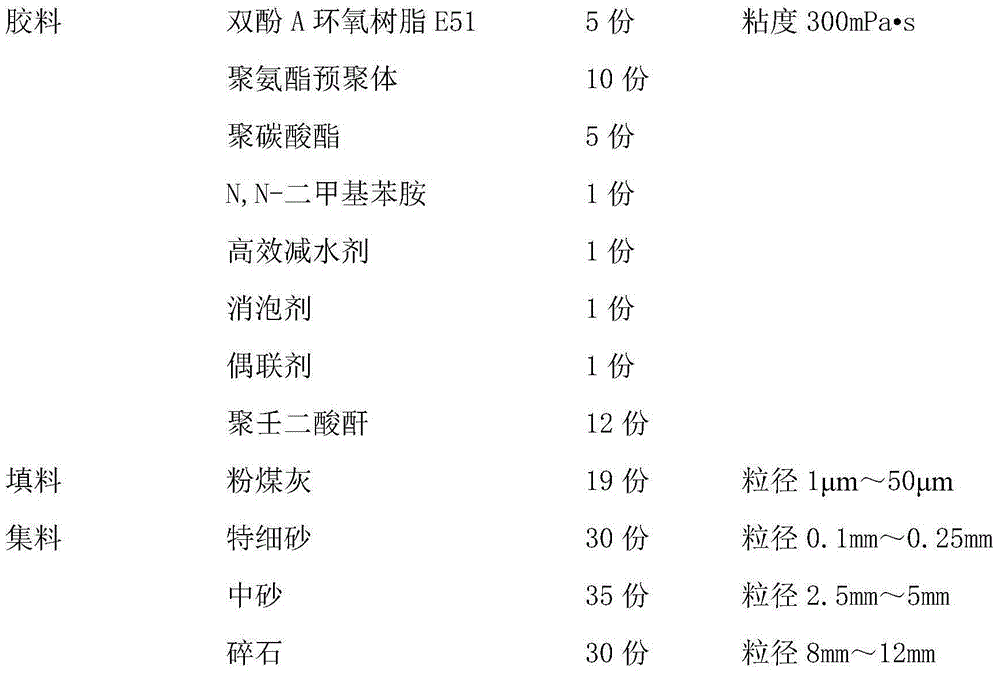

Embodiment 1

[0035]

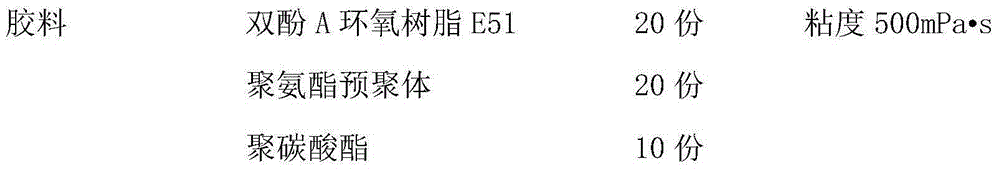

Embodiment 2

[0037]

[0038]

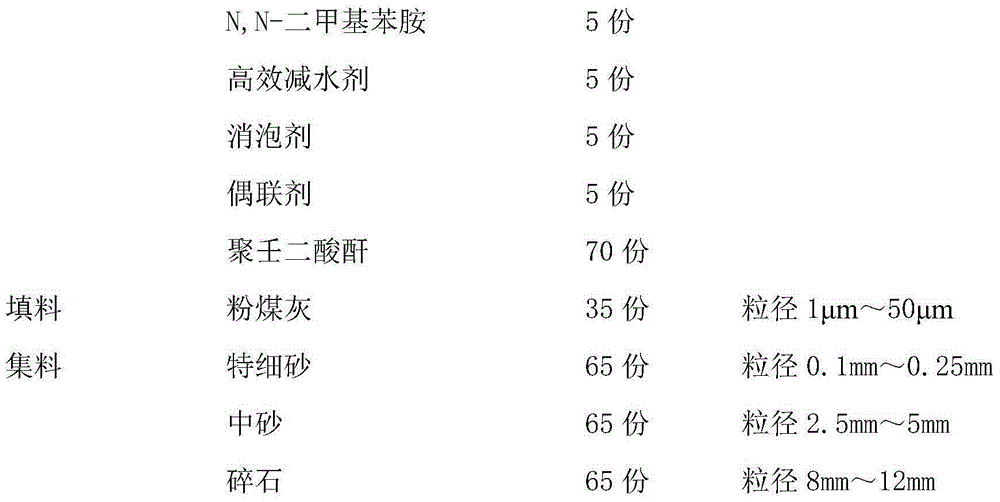

Embodiment 3

[0040]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses high-strength super-toughness resin concrete which is composed of aggregate, packing and a sizing material. The high-strength super-toughness resin concrete is characterized in that the sizing material is composed of resin A and a curing agent B. The resin A is composed of epoxy resin, polyurethane prepolymer, polycarbonate and a functional agent. The weight percentage of the resin A and the curing agent B is 1:1-2:1, and the packing is inorganic powder. The aggregate is composed of super-fine sand, coarse sand and gravel. The epoxy resin is bisphenol A epoxy resin. The functional agent comprises accelerant, a water reducing agent, a defoaming agent and a coupling agent. The curing agent is long-chain aliphatic series anhydride. The high-strength super-toughness resin concrete has the advantages that strength is high and even, cracking and breaking do not happen, the deformation capability is good, the elasticity recovery rate is high, and the high-strength super-toughness resin concrete is not prone to permanent deformation at a high temperature.

Description

technical field [0001] The invention relates to a resin concrete and a manufacturing method thereof. In particular, it relates to a high-strength super-toughness resin concrete and a manufacturing method thereof. Background technique [0002] With the rapid development of expressways, the structural types of expressway bridges have been continuously innovated, and the spans of bridges have become larger and larger. Two types of concrete pavement. Cement concrete pavement has low cost, good wear resistance, and is suitable for heavy-duty traffic, but the maintenance period is long, and it is troublesome to repair in the future. Asphalt concrete pavement is light, easy to maintain and open to traffic, but it is easy to age and deform. At present, the noise caused by concrete vibration or rolling during construction has become an important problem that needs to be solved. In order to solve the above problems, it is particularly necessary to develop high-strength, super-toug...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B26/18

Inventor 赵岩荆王洪超周岚覃勉李小鹏

Owner NANJING ROAD KEEPER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com