Outlast temperature-adjusting fiber blended yarn and production method thereof

A temperature-adjusting fiber and production method technology, applied in yarn, textiles and papermaking, etc., can solve the problems of fiber strength decline, smooth surface, poor cohesion, easy to generate static electricity, etc., to achieve uniformity, good tensile properties, good The effect of thermoregulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

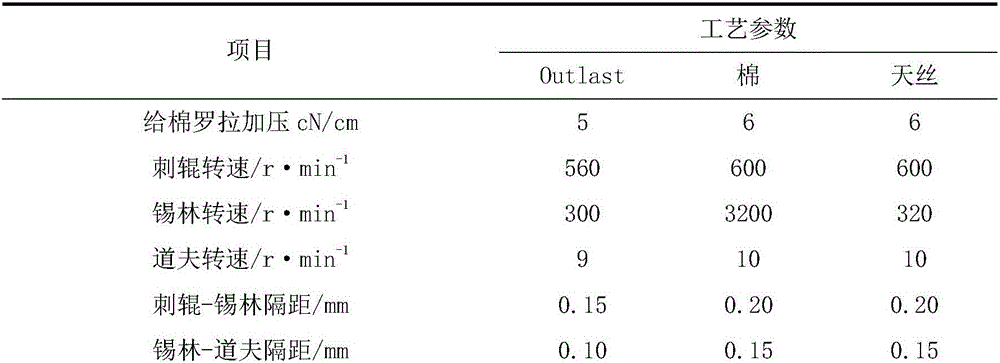

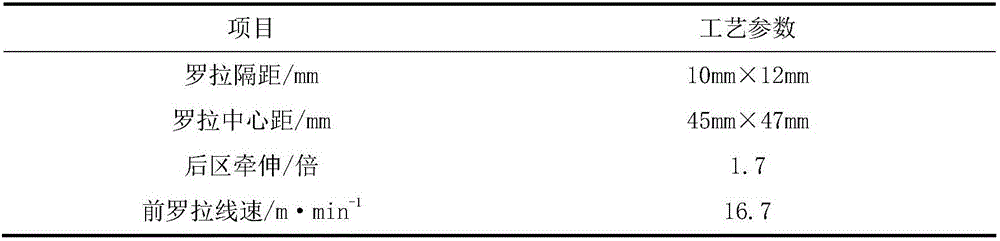

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the present invention, the technical solutions of the present invention will be clearly and completely described below in conjunction with examples.

[0026] (1) Raw material selection: Choose Outlast temperature-adjusting fiber length of 38.0mm, linear density of 1.6dtex, moisture regain of 13.0%, breaking strength of 1.8cN / dtex, breaking elongation of 17.6%; cotton fiber length of 30.0mm , the linear density is 1.6dtex, the moisture regain is 9.2%, the breaking strength is 2.0cN / dtex, and the breaking elongation is 13.2%; the tencel fiber length is 38.0mm, the linear density is 1.7dtex, the moisture regain is 11.0%, The strength is 2.9cN / dtex - , The elongation at break was 9.5%.

[0027] (2) The ratio of the above raw materials is designed as Outlast temperature-regulating fiber / cotton / Tencel40 / 36 / 24.

[0028] (3) Lay the Outlast fiber evenly on the plastic film, spray a certain amount of antistatic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com