Method for improving filter efficiency of melt-blowing non-woven fabric

A technology of melt-blown nonwovens and filtration efficiency, which is applied in textiles and papermaking, fiber treatment, physical treatment, etc. It can solve the problems of insufficient charge and charge stability, poor anti-aging performance of filter materials, and filtration efficiency to be improved. , to achieve good charge storage stability, improved anti-aging performance, and excellent anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

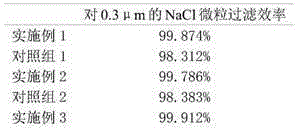

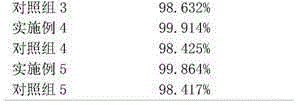

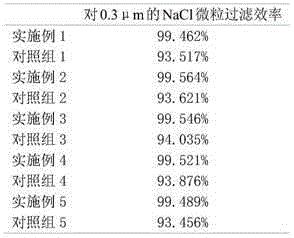

Examples

Embodiment 1

[0025] Polarization of Meltblown Nonwovens

[0026] 1) Equipment cleaning: Wipe the electrode of the plasma treatment device and the electrode of the corona charging device, and the electrified conveying roller, guide roller and roller with ethanol, respectively, to prevent the occurrence of tip discharge and breakdown of the melt-blown nonwoven fabric. This results in a decrease in filtration performance.

[0027] 1.1) Threading: The melt-blown non-woven fabric was passed through the electrode of the plasma treatment device and the electrode of the corona charging device in turn, and passed through the charged conveying roller of the corona charging device.

[0028] 2) Plasma treatment: In an open atmosphere, at room temperature, relative humidity 30%, voltage 100V, current 0.20A, output frequency 20.0KHz, plasma treatment is performed on the melt-blown nonwoven.

[0029] 3) Corona charging treatment: in an open atmosphere, at room temperature, relative humidity 30%, voltage...

Embodiment 2

[0032] Polarization of Meltblown Nonwovens

[0033] 1) Equipment cleaning: Wipe the electrode of the plasma treatment device and the electrode of the corona charging device, and the electrified conveying roller, guide roller and roller with ethanol, respectively, to prevent the occurrence of tip discharge and breakdown of the melt-blown nonwoven fabric. This results in a decrease in filtration performance.

[0034] 1.1) Threading: The melt-blown non-woven fabric was passed through the electrode of the plasma treatment device and the electrode of the corona charging device in turn, and passed through the charged conveying roller of the corona charging device.

[0035] 2) Plasma treatment: in an open atmosphere, at room temperature, relative humidity 45%, voltage 150V, current 0.50A, output frequency 10.0KHz, plasma treatment is performed on the meltblown nonwoven.

[0036] 3) Corona charging treatment: in an open atmosphere, at room temperature, relative humidity 45%, voltage ...

Embodiment 3

[0039] Polarization of Meltblown Nonwovens

[0040] 1) Equipment cleaning: Wipe the electrode of the plasma treatment device and the electrode of the corona charging device, and the electrified conveying roller, guide roller and roller with ethanol, respectively, to prevent the occurrence of tip discharge and breakdown of the melt-blown nonwoven fabric. This results in a decrease in filtration performance.

[0041] 1.1) Threading: The melt-blown non-woven fabric was passed through the electrode of the plasma treatment device and the electrode of the corona charging device in turn, and passed through the charged conveying roller of the corona charging device.

[0042] 2) Plasma treatment: in an open atmosphere, at room temperature, relative humidity 75%, voltage 700V, current 2.50A, output frequency 5.0KHz, plasma treatment is performed on the meltblown nonwoven.

[0043] 3) Corona charging treatment: in an open atmosphere, at room temperature, relative humidity 75%, voltage -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com