Gluing composition device applied to equipment for processing paper for daily use and implementation method of gluing composition device

A technology for household paper and composite devices, which is applied in lamination devices, mechanical processing/deformation, chemical instruments and methods, etc., can solve problems such as poor gluing and compounding effects, inability to adjust the amount of gluing, and low production efficiency. Achieve the effects of good gluing compound effect, simple structure and guaranteed production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

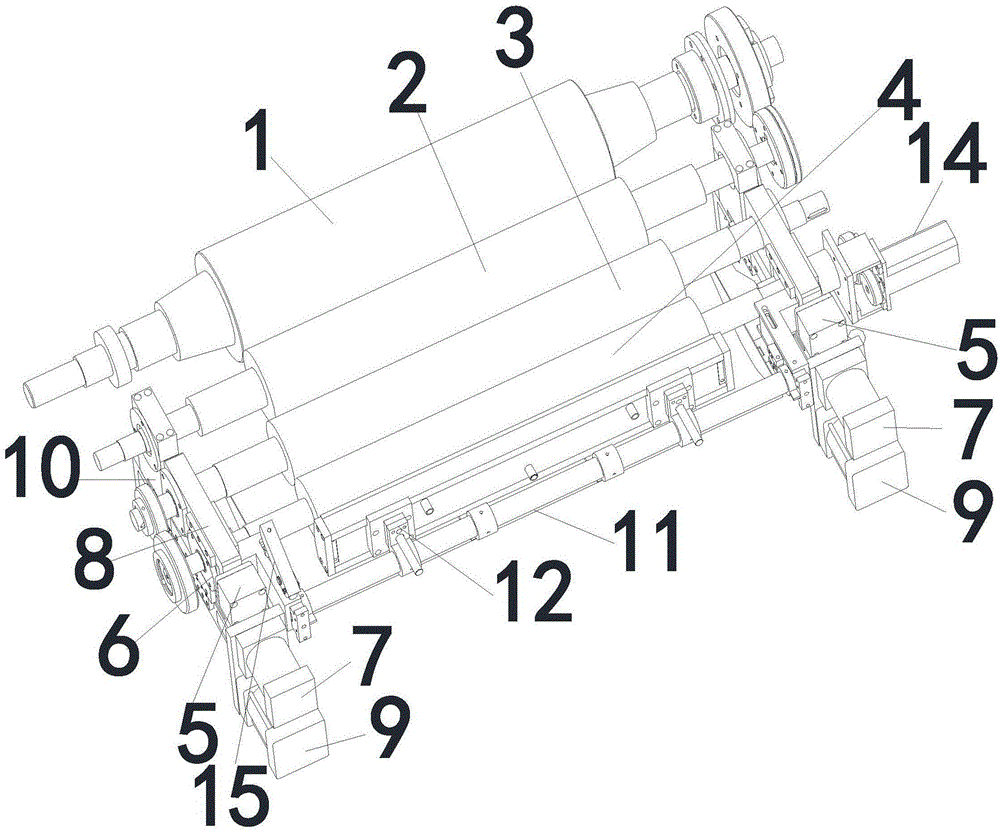

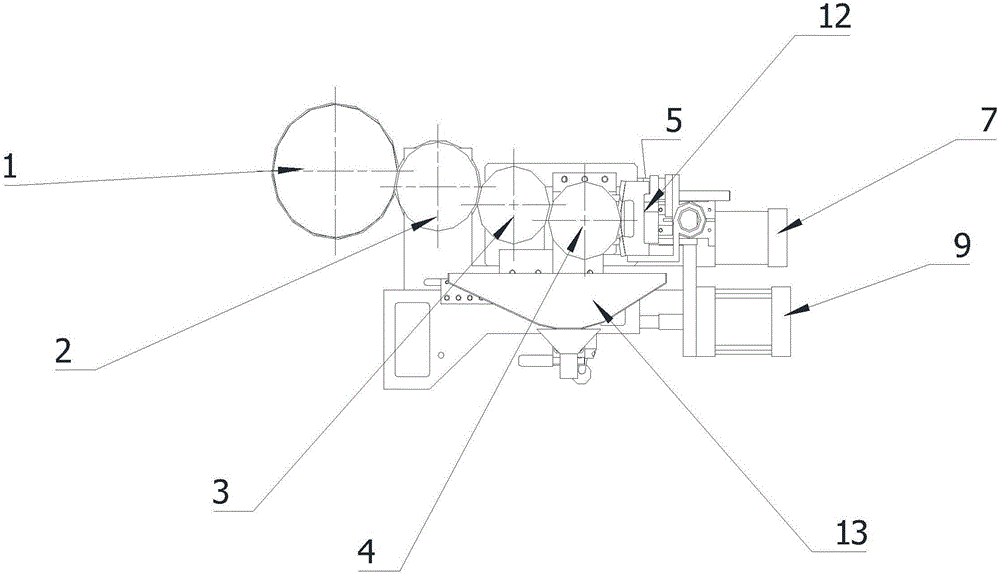

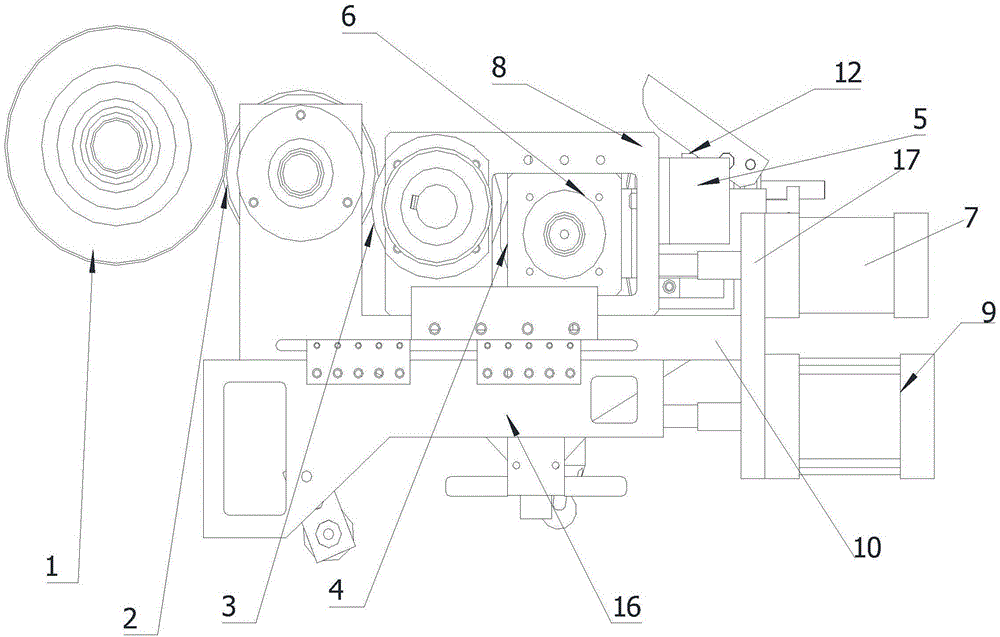

[0041] Such as Figure 1~3 As shown, a gluing composite device for processing household paper equipment includes an embossing roller 1, a composite rubber roller 2, a transfer rubber roller 3 and an anilox roller 4 arranged tangentially in sequence, and the anilox roller 4 is two There is a first drive 5 at the end, and the first drive 5 is connected to the anilox roller 4 through the first slide plate 6; a second drive 7 is provided under the first drive 5, and the second drive 7 is connected with the transfer rubber roller 3 through the second slide plate 8 connection, the first slide plate 6 and the anilox roller 4 are set in the second slide plate 8; the third drive 9 is provided below the second drive 7, the second drive 7 and the third drive 9 are fixed on the fixed plate 17, and the second The slide plate 8 is connected with the chute of the third slide plate 10, the chute of the third slide plate 10 is connected with the fixed slide plate 16, the third drive 9 is conne...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the first drive 5, the second drive 7 and the third drive 9 in this embodiment are all motors; 40mm longer than the roll surface of the embossing roller 1; the roll surface of the composite rubber roller 2 is 20mm smaller than the roll surface of the transfer rubber roller 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com