2,000 MPa durable parallel steel wire stay cable of highway and railway cable-stayed bridge

A technology for road-rail dual-purpose, cable-stayed bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems that cannot meet the needs of road-rail dual-purpose cable-stayed bridges, restrict the application of cable-stayed cables, etc., and achieve the improvement of fretting fatigue Effects of abrasion, prevention of local damage, and enhancement of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

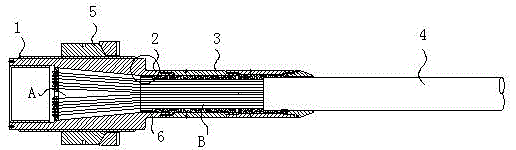

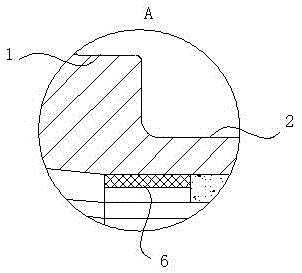

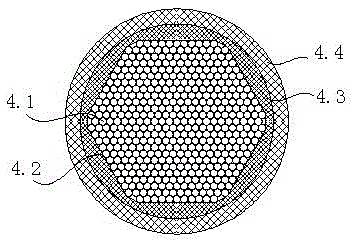

[0020] Such as figure 1 with 2 As shown, the stay cable structure in this embodiment includes an anchor cup 1, an anchor ring 5, a connecting cylinder 3 and a cable body 4. The front end of the anchor cup 1 is formed with a boss 2, and the anchor cup 1 and the boss 2 are integrated. The outer diameter of the anchor cup 1 is larger than that of the boss 2, forming a variable diameter structure. The transition step between the boss 2 and the anchor cup 1 is a large fillet shape, and the radius of the fillet is 5-10mm. The connecting cylinder 3 and the boss 2 The inner and outer joints can effectively prevent rainwater from infiltrating into the connection between the connecting cylinder 3 and the anchor cup 1 to induce corrosion. The anchor cup 1 forms a tapered cavity A that gradually expands from the outside to the inside. The entrance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com