Fluid dynamic pressure type mechanical seal used for nuclear main pump and mechanical seal system of nuclear main pump

A technology of mechanical sealing and fluid dynamic pressure, which is applied to the components of pumping devices for elastic fluids, liquid fuel engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

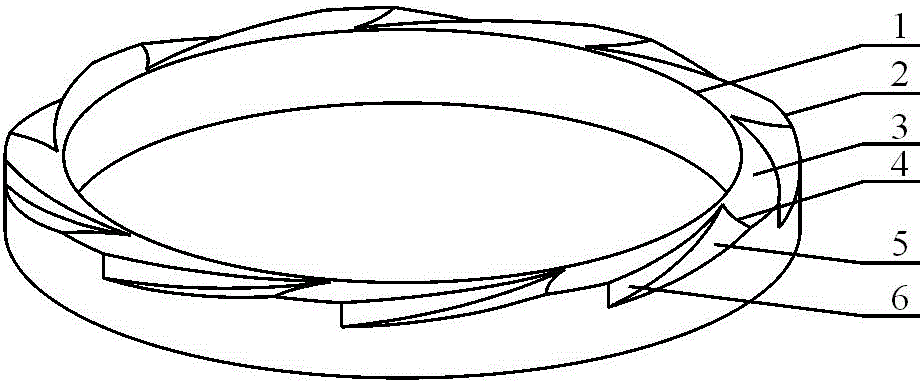

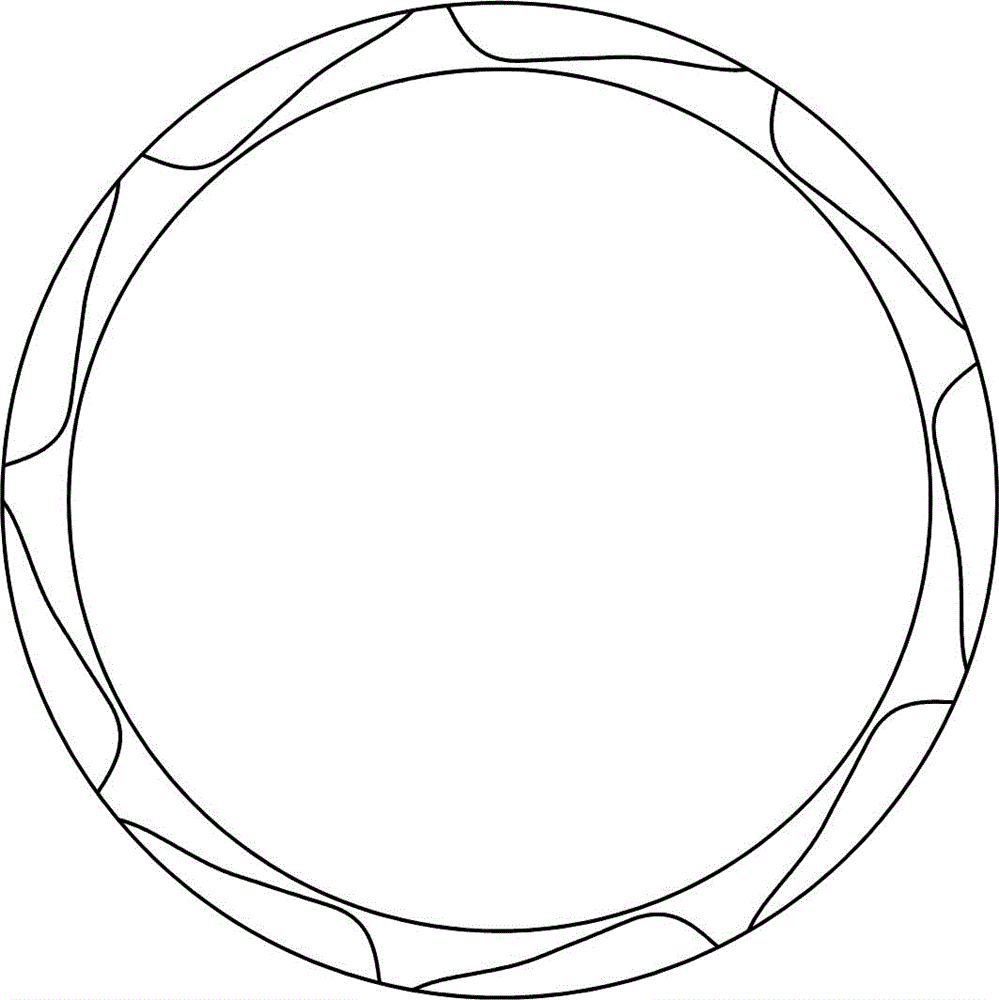

[0105] Example 1: Please refer to figure 1 , figure 2 and image 3 .

[0106] A hydrodynamic mechanical seal for a nuclear main pump, including a static ring and a moving ring. A shallow groove is provided on the sealing end face of the static ring. When working, the sealing end faces of the two rings are nearly fitted, and there is a sealing medium in the gap , the rotating shaft drives the moving ring to rotate relative to the static ring. The outer diameter side of the sealing end face is the high pressure test, that is, the upstream side, and the inner diameter side is the low pressure test, that is, the downstream side. The sealing medium leaks through the gap between the two sealing end faces. The shallow groove is a kind of Curved surface groove, the bottom surface of the curved surface groove is a curved surface. The curved surface is a single surface that the seal ring makes with respect to a circle with a radius of 175 mm and an inclination angle of 0.0002 radians...

Embodiment 2

[0109] Example 2: Please refer to Figure 4 , Figure 5 , Image 6 and Figure 7 .

[0110] The difference from Embodiment 1 lies in the different shapes of the curved grooves. Figure 4 Indicates the shape of the curved surface groove on the sealing end surface in Example 2, Figure 5 Yes Figure 4 A top view of the shape shown, Image 6 Yes Figure 4 The schematic diagram of the surface groove formation is shown, Figure 7 Yes Image 6Top view of the schematic shown. The said motion rule is that the circle inclined to the seal end face performs a composite motion consisting of a linear motion slightly inclined to the seal end face and a rotation around the axis of the seal ring. In this embodiment, the curved surface groove formed is composed of a smooth curved surface, which smoothly transitions to the sealing end surface without steep side walls, and the intersection line between the curved surface and the sealing end surface is a smooth curve, and the distance b...

Embodiment 3

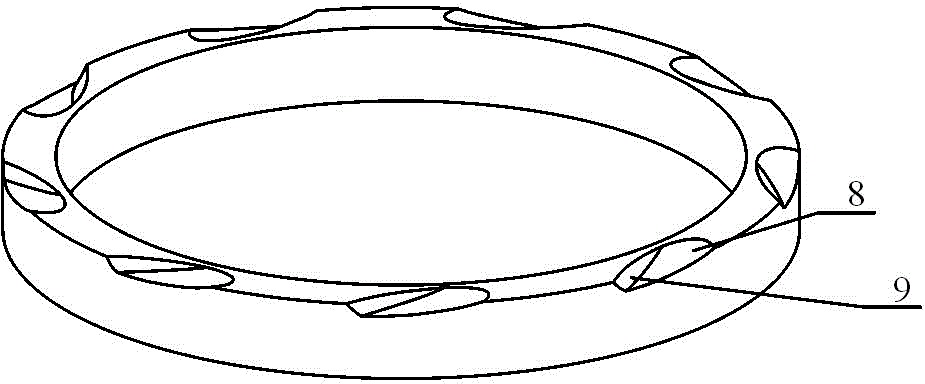

[0111] Example 3: Please refer to Figure 8 , Figure 9 and Figure 10 .

[0112] The difference from the previous embodiments lies in the different shapes of the curved grooves. Figure 8 Indicates the shape of the curved surface groove on the sealing end surface in Example 3, Figure 9 Yes Figure 8 A top view of the shape shown, Figure 10 Yes Figure 8 Schematic diagram of surface groove formation shown. The motion rule is a composite motion composed of a rotation with a straight line parallel to the sealing end surface as an axis and a rotation around the axis of the seal ring. In this embodiment, the intersection line between the curved surface groove and the sealing end surface is a smooth curve, and the curved surface groove is generally symmetrical with respect to the radial line of the seal ring, and can generate enough pressure when the pump shaft rotates forward or reverse. fluid dynamic effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com