A six-degree-of-freedom quasi-zero-stiffness vibration isolation system based on a stewart platform

A quasi-zero stiffness, vibration isolation system technology, applied in the direction of non-rotational vibration suppression, etc., to achieve high precision, improve vibration isolation effect, and large support stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in combination with specific embodiments.

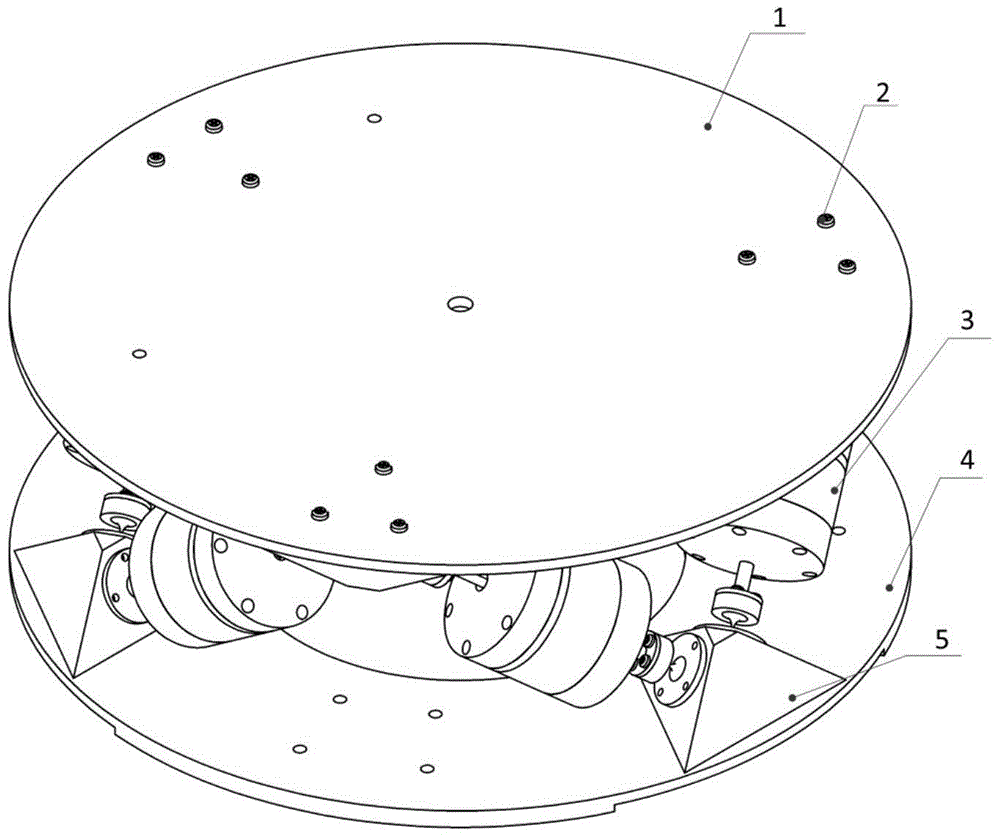

[0026] Such as figure 1 As shown, a quasi-zero stiffness vibration isolation system based on a Stewart platform in the present invention includes an upper platform 1 , a lower platform 4 , six identical legs 3 , a hinge block 5 , and a first screw 2 . The two ends of supporting leg 3 are fixed on the hinge block 5, respectively have three hinge blocks 5 on upper platform 1 and lower platform 4, and three hinge blocks are distributed in the form of equilateral triangle. The hinge block 5 is fixed on the upper platform 1 and the lower platform 4 by the first screw 2 . The Stewart platform has a cubic structure, and two adjacent legs are perpendicular to each other. Since the lengths of the six outriggers are variable, the upper platform has six degrees of freedom relative to the lower platform. Installing the equipment that needs vibration isolation on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com