Slicing-type manual multi-way reversal valve

A multi-way reversing valve and split-type technology, which is applied in the field of hydraulic components, can solve the problems of large volume and mass of multi-way reversing valves, difficulty in meeting machining accuracy requirements, deformation of valve body holes, etc., and achieve enhanced anti-pollution ability , improve oil supply efficiency, enhance the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

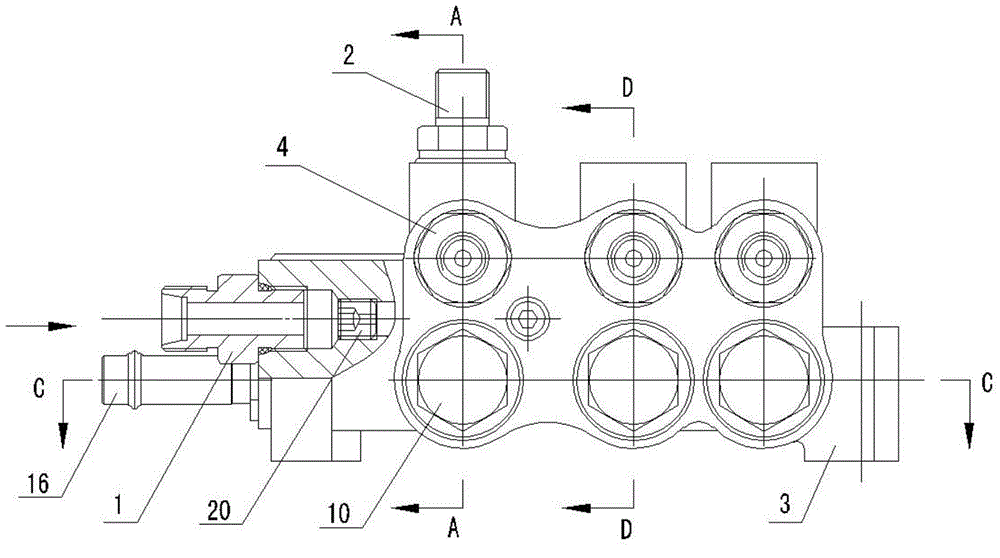

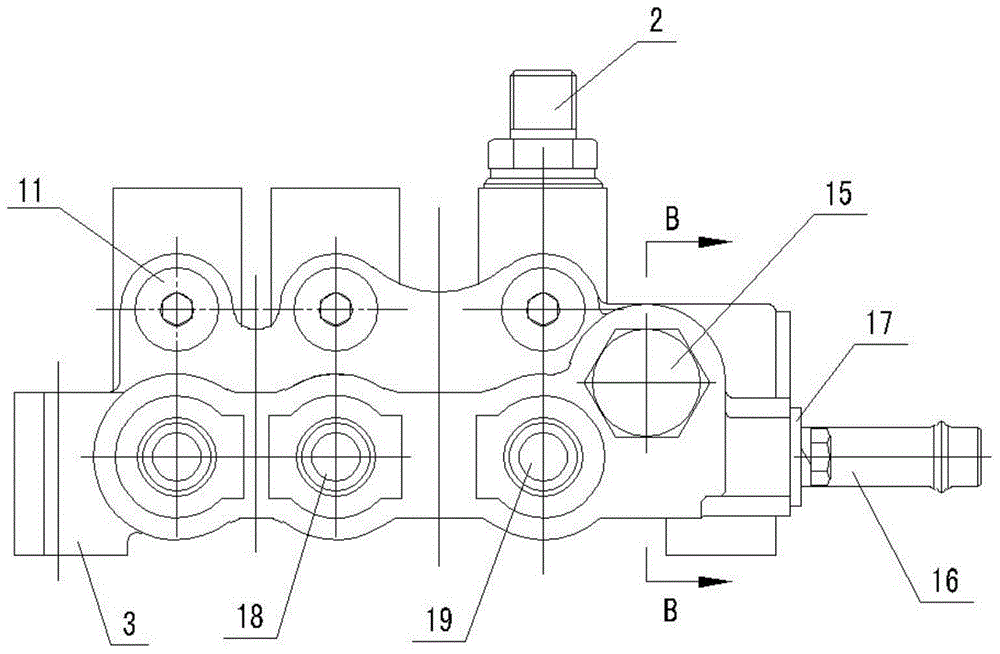

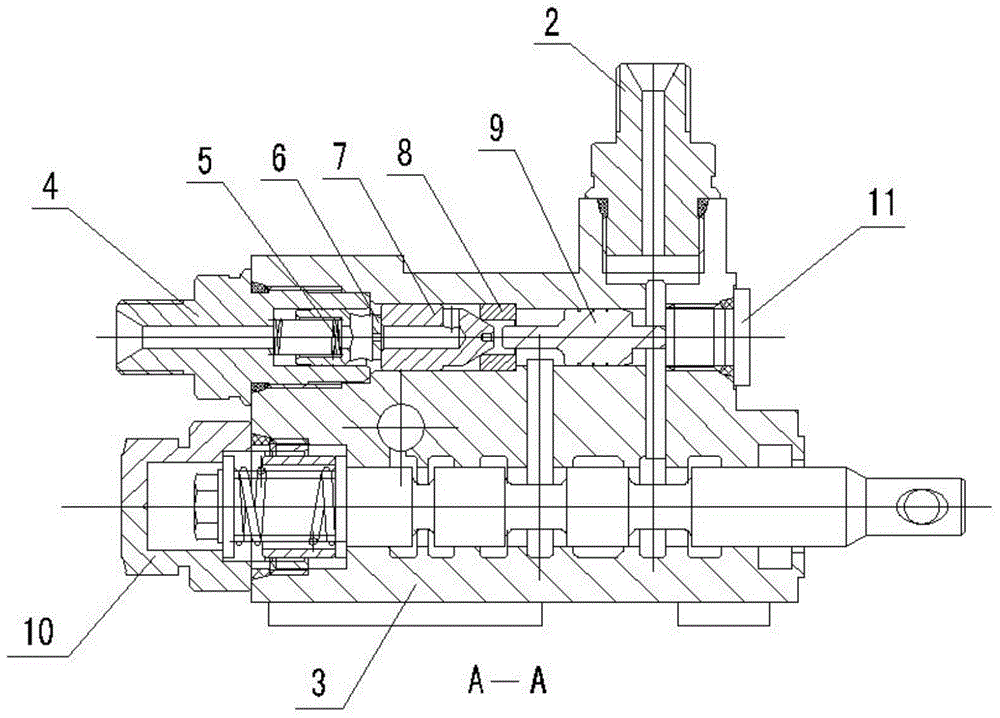

[0031] The structural form of the segmented manual multi-way reversing valve in this embodiment is:

[0032] see figure 1 , figure 2 , the reversing valves are arranged in parallel in the valve body 3, the oil inlet of the main throttle valve 20 located at one end of the valve body 3 communicates with the main oil inlet joint 1 of the valve body 3 to form the main oil circuit, and the main throttle valve 20 The oil outlets are connected to the corresponding reversing valves through independent oil passages; the pressure oil is introduced from the oil inlet joint 1, enters the hydraulic control check valve 21 in the reversing valve, and the outlet of the hydraulic control check valve 21 The oil ports are connected to the working oil cylinders of each branch, and flow back to the oil tank through the pressure block 17 and the oil return joint 16 in sequence. This structure is compact and simple as a whole, and it is especially easy to independently fulfill the control require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com