Multi-one-way-valve combined energy-saving reciprocating oil supply device capable of achieving self-adaptation in-advance mutual starting

A technology of oil supply device and one-way valve, applied in the direction of charging system, engine components, liquid fuel feeder, etc. Adapt to problems such as adjusting the motion stroke, achieve the effect of improving fuel supply economy, safe and reliable fuel supply process, and solving the instantaneous and sharp rise of fuel pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

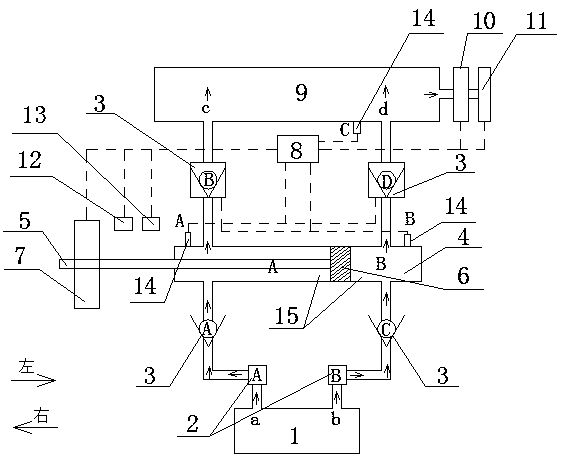

[0018] Embodiment: multiple one-way valves combined with self-adaptive advance mutual start energy-saving reciprocating oil supply device, including oil supply device and electrical control system, the oil supply device includes fuel tank 1, filter 2, reciprocating oil supply pump 4 and electronically controlled fuel injection device 11; reciprocating oil supply pump 4 is composed of piston rod 5, piston 6 and oil supply chamber 15, oil supply chamber 15 is divided into left oil supply chamber 15A and right oil supply chamber 15B through piston 6; left oil supply chamber 15A is provided with The oil supply circuit ac, the oil supply circuit bd is set on the right oil supply chamber 15B, the lower end of the two oil supply circuits is connected to the fuel tank 1, and the upper end is connected to the voltage stabilizer 9, and the right end of the voltage stabilizer 9 is provided with a flow limiting valve 10 and an electric control The fuel injector 11 ; the flow limiting valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com