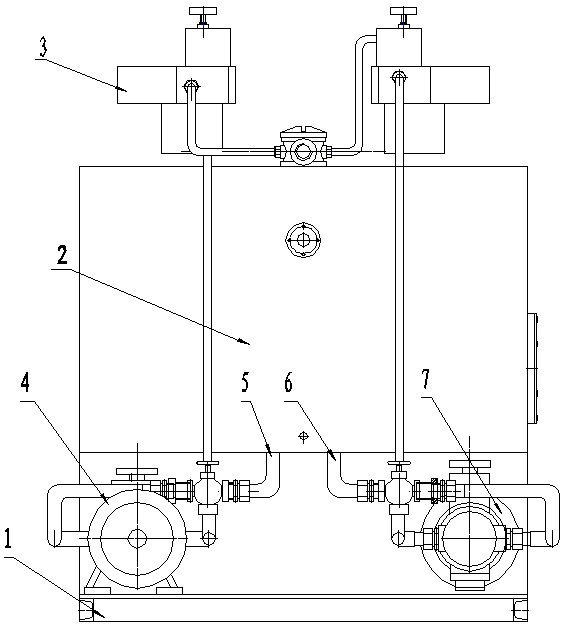

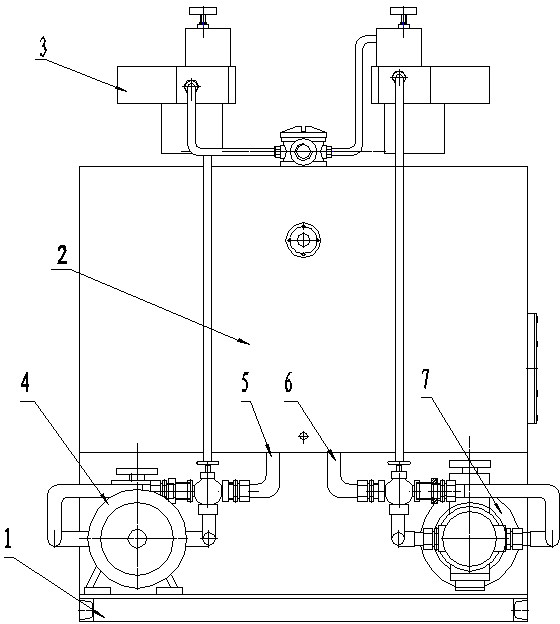

Underneath type double-pump alternating current hydraulic working station for hydraulic steering engine

A hydraulic workstation and steering gear technology, applied in the field of hydraulic systems, can solve the problems of increasing product processing and assembly, increasing the total installation space, increasing product weight, etc., to reduce the processing and assembly, compact structure, supply The effect of improving oil efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] A double-pump type AC hydraulic workstation with a hydraulic steering gear under it, mainly including a machine base 1, an oil tank 2, a special valve group 3 for steering gear, a first motor pump group 4, a second motor pump group 7, a first oil suction port 5 and The second oil suction port 6; the first motor pump group 4 and the second motor pump group 7 are placed on the base 1 under the fuel tank 2, the first motor pump group 4 is connected to the fuel tank 2 through the first oil suction port 5, and the second motor pump group The pump group 7 is connected to the oil tank 2 through the second oil suction port 6, and the special valve group 3 for steering gear is connected to the first motor pump group 4 and the second motor pump group 7 respectively.

[0008] The invention is applicable to the configuration requirements of hydraulic steering gears of various models and specifications ranging from 63 to 900 kN·m for the configuration requirements of the lower-mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com