Gas injection valve with buffer mechanism

A buffer mechanism and gas injection technology, applied in the valve's device for absorbing fluid energy, sliding valve, valve details, etc., can solve the problems of valve life influence, collision, weak buffer effect of injection valve, etc., to reduce collision wear and response. Fast, avoids wear or sticking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

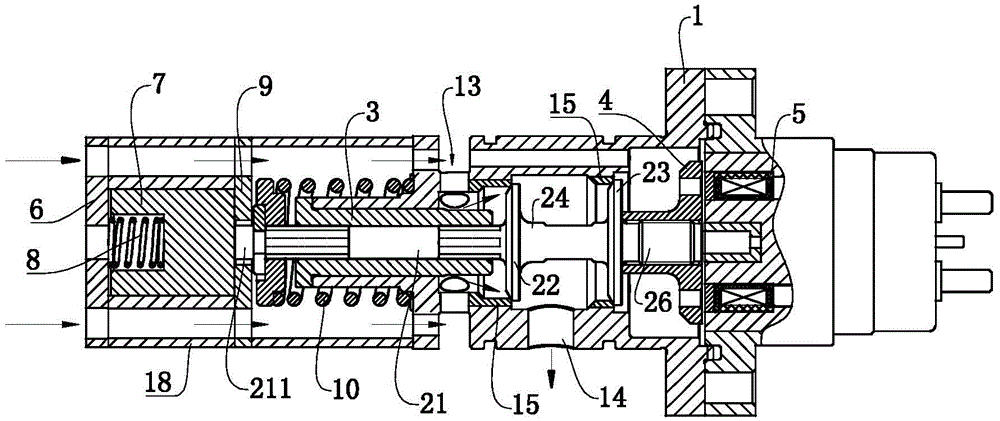

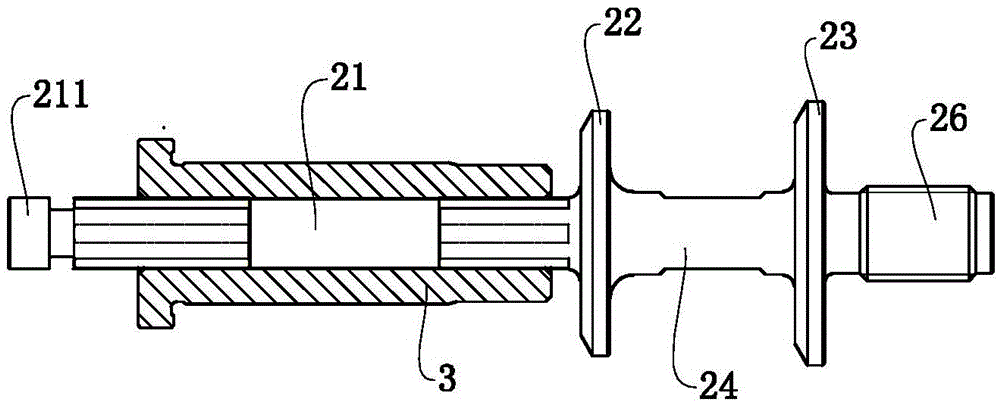

[0027] combine figure 1 and figure 2 Commonly shown, a gas injection valve with a buffer mechanism, the body of the valve body 1 is provided with an air inlet 13 and an air outlet 14, the valve body 1 is provided with a valve seat 15 and a valve core sleeve 3, the valve seat 15 is installed on the valve body 1, or the valve seat 15 is integrated with the valve body 1 (when split manufacturing, the valve seat 15 can be made of more wear-resistant materials), the air inlet 13 and the valve seat Air intake passage is provided between 15. A slidable valve core is installed in the installation hole of the valve core cover 3, and the valve core includes a valve stem portion 21, a valve plate portion and a valve core tail portion 26 arranged in sequence, and the valve plate portion is matched with the valve plate seat 15. For ease of description, the position of the valve stem portion 21 is defined as the “front direction”, and the position of the valve core tail 26 is defined as ...

no. 2 example

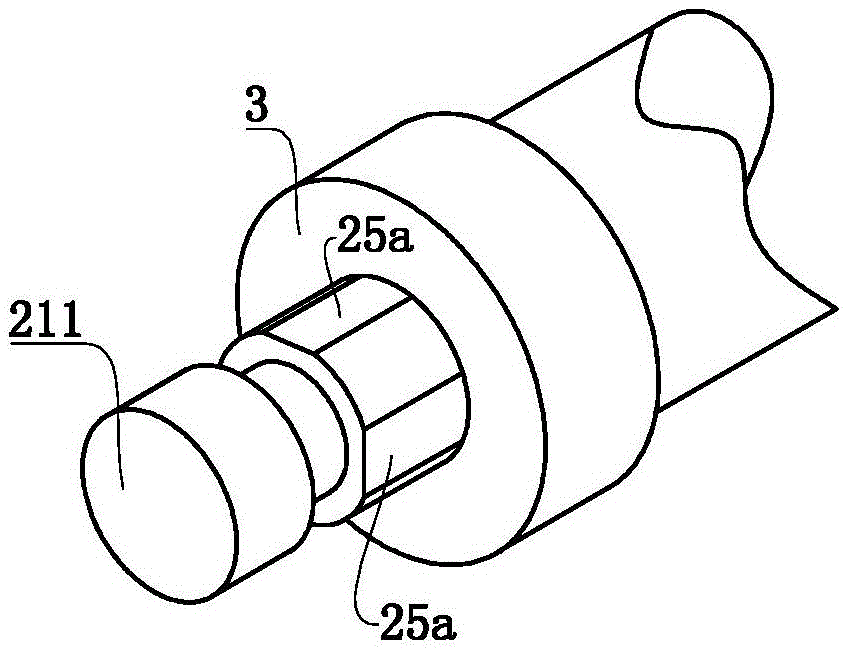

[0039] Such as Figure 4 As shown, its structure is basically the same as that of the first embodiment, the difference is that a groove 25b extending in the axial direction is provided on the peripheral surface of the stem part 21 to replace the notch 25a, and the effect is basically the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com