A double-layer punch

A punching, double-layer technology, applied in the field of parts processing, can solve the problems of not being able to ensure the placement of the workpiece, affecting the qualified rate of the workpiece, stamping deviation, etc., to achieve the effect of simple structure, improving the qualified rate, and buffering the falling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

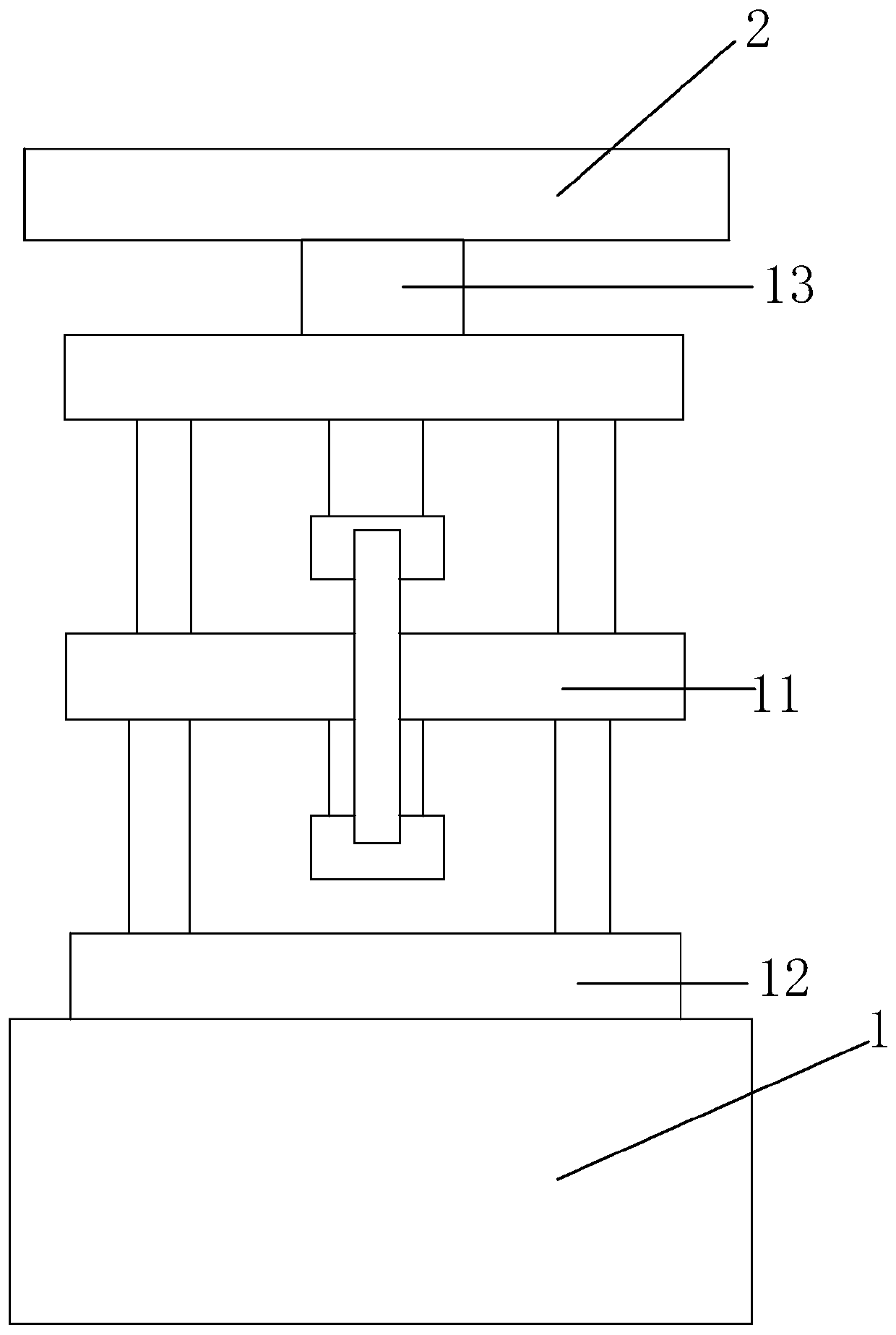

[0029] Embodiment 1: a kind of double-deck punch, such as figure 1 As shown, it mainly includes a frame 1, an upper working plate 11, a lower working plate 12, and a hydraulic cylinder 13 positioned at the top of the frame 1. The hydraulic cylinder 13 is an executive power element, and the workpieces to be processed are respectively placed on the upper working plate 11 and the On the lower working plate 12, and under the action of the hydraulic cylinder 13, two workpieces can be punched simultaneously.

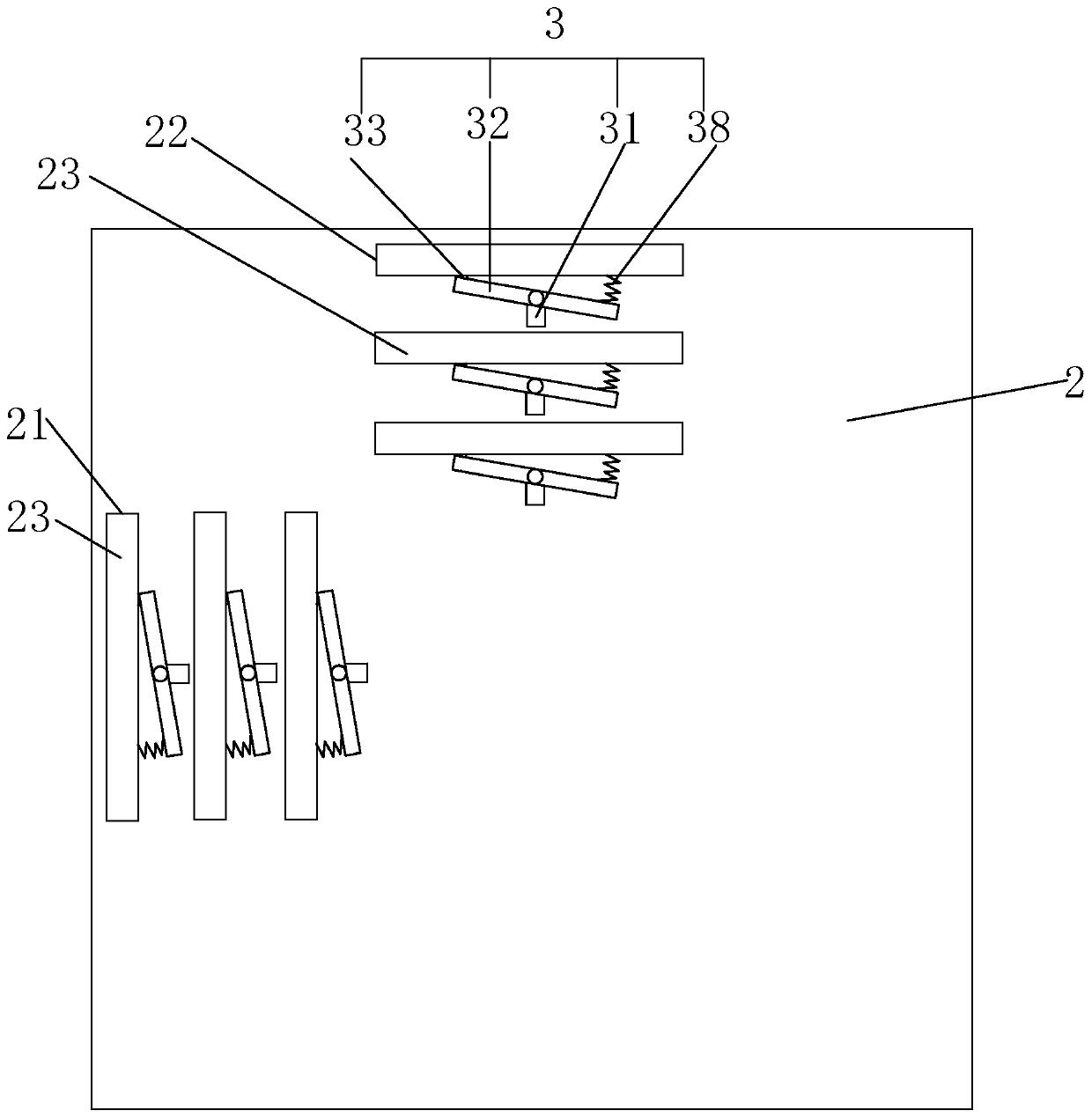

[0030] Such as figure 1 As shown, at this time, a rectangular adjustment plate 2 is fixed horizontally on the top of the hydraulic cylinder 13, as figure 2 As shown, one end of the hydraulic cylinder 13 on the adjustment plate 2 is provided with a plurality of Y-direction limiting channels 21 from the inside to the outside, and the adjustment plate 2 is provided with a plurality of X-direction slots 21 from the inside to the outside on one side of the hydraulic cylinder 13. ...

Embodiment approach

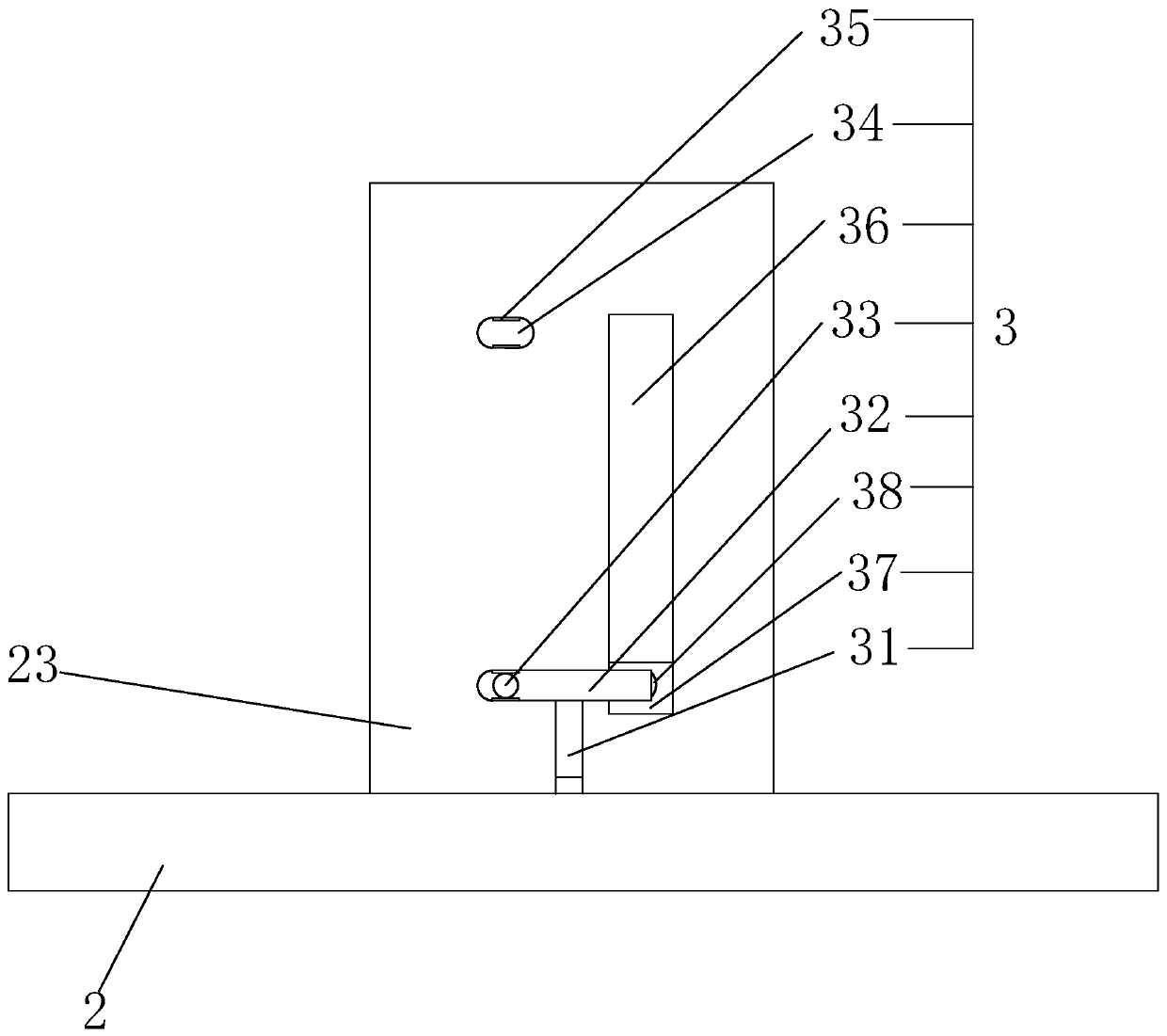

[0032]The specific embodiment: before the workpiece is processed, the positioning plate 23 is all in the non-working state under the effect of the limit mechanism 3, that is, it is all in the place away from the upper working plate 11. At this time, the electromagnet 35 is all in the energized state. The limit rod 33 in the positioning mechanism 3 is inserted into the limit hole at the position of the positioning plate 23 near the bottom, and the connecting spring 38 is in a stretched state; when the workpiece needs to be processed, the workpieces to be processed are respectively placed on On the surface of the upper working plate 11 and the lower working plate 12, and according to the size of the workpiece, select the two positioning plates 23 at the required positions of the Y-direction limiting channel 21 and the X-direction limiting channel 22, and select the positioning of the appropriate position. After the plate 23, the electromagnet 35 at this position is controlled to ...

Embodiment 2

[0036] Embodiment 2: a kind of double-deck punching machine, the difference with embodiment 1 is, as Figure 6 As shown, at this moment, on the adjustment plate 2, a plurality of buffer mechanisms 4 for controlling the falling speed of the positioning plate 23 are provided. The side wall of the positioning plate 23 near the fixed block 41 and located at the upper end position are fixedly provided with a connecting block 42, the bottom surface of the connecting block 42 is fixedly provided with a fixed sleeve 44, and the sliding inside the fixed sleeve 44 is provided with a telescopic rod 45 The upper surface of the fixed block 41 is fixedly provided with a buffer spring, and the end of the buffer spring away from the fixed block 41 is connected and fixed with the lower surface of the fixed sleeve 44, and the outer circumferential surface of the connecting rod 32 conflicts with the inner ring of the buffer spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com