Heat recovery decentralized evaporative cooling air conditioning system for tall spaces

An evaporative cooling air conditioner and high space technology, which is applied in the field of heat recovery type distributed evaporative cooling air conditioning system, can solve problems such as affecting the health, comfort and work efficiency of workers, unfavorable storage of goods, and hot air circulation in the workshop, etc. To achieve the effect of saving costs, ensuring air quality and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

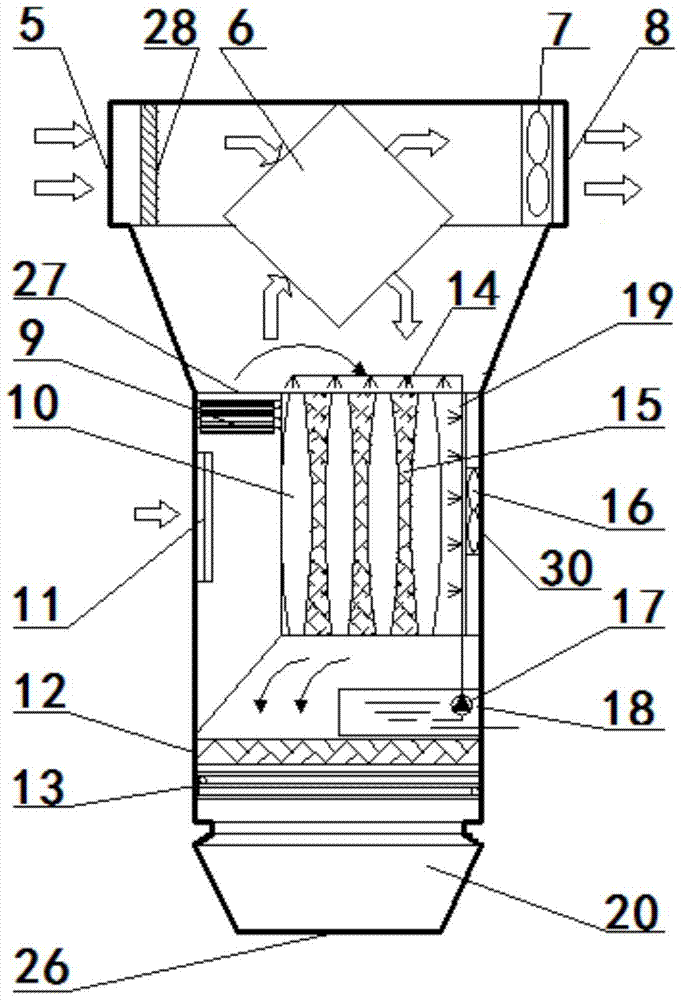

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

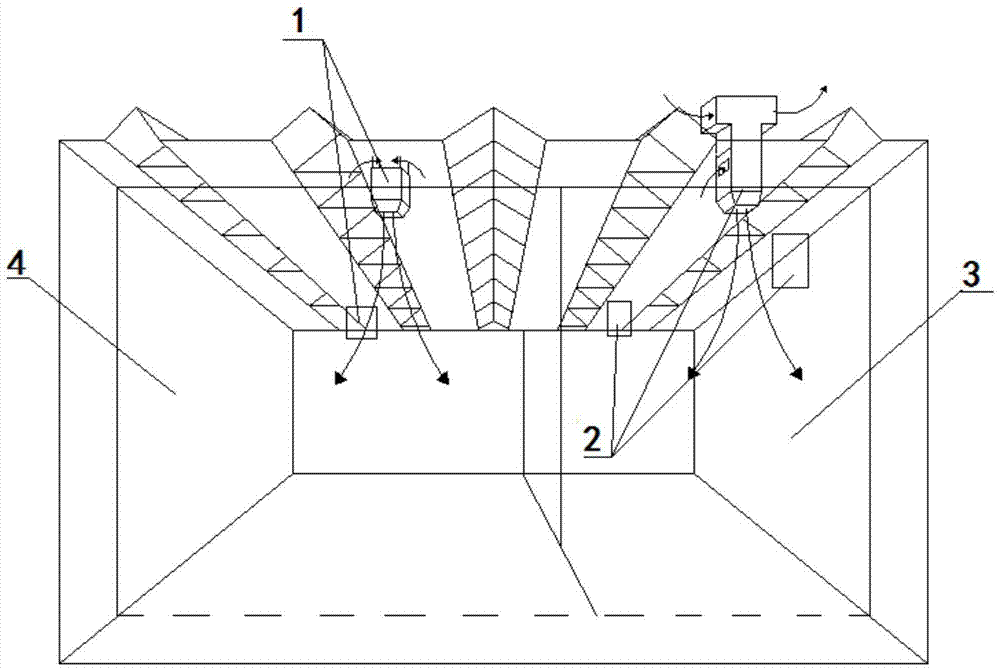

[0028] The present invention is suitable for heat recovery type distributed evaporative cooling air conditioning system in tall and large spaces, and its structure is as follows: figure 1 As shown, it consists of a heat recovery type winter and summer dual-purpose evaporative cooling air treatment system installed in the workshop work area 4 and a dust removal circulation heating system for high and large spaces installed in the workshop cargo area 3 .

[0029] The heat recovery type winter and summer evaporative cooling air handling system is composed of multiple heat recovery type winter and summer evaporative cooling air handling units 1 .

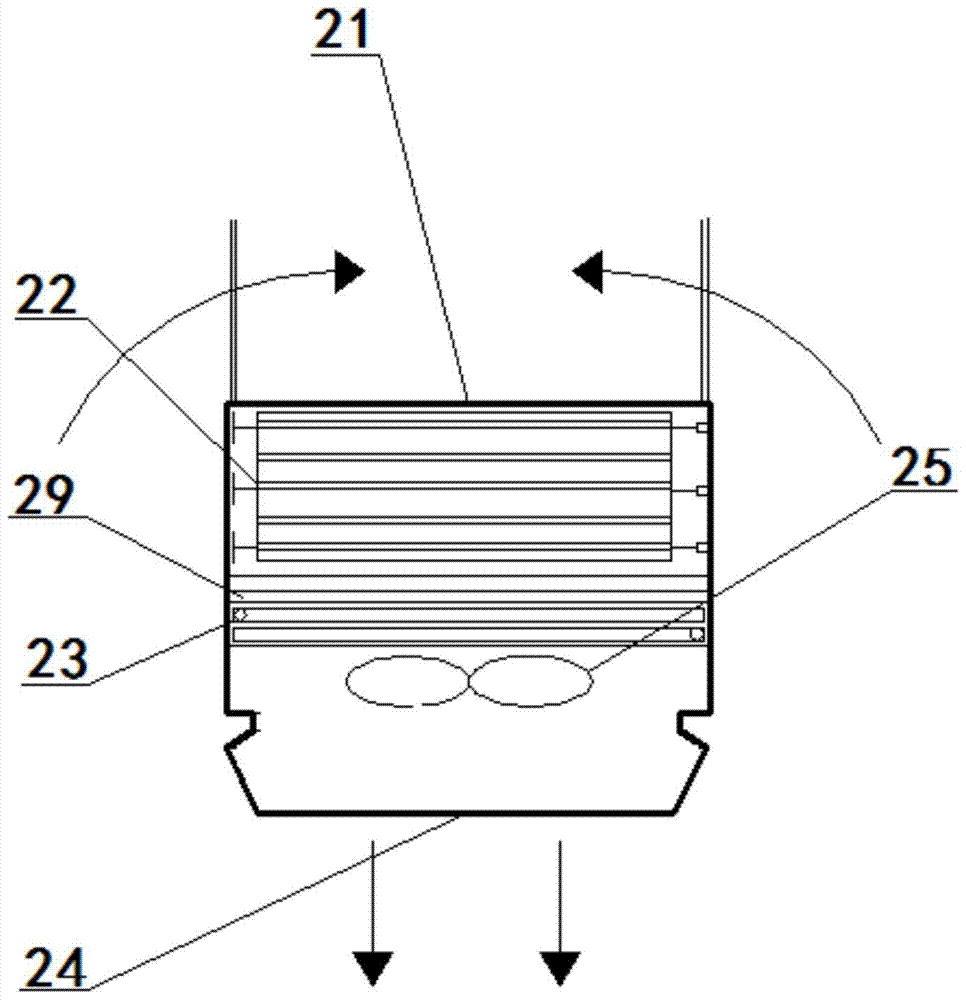

[0030] The dust removal circulating heating system for tall and large spaces is composed of multiple dust removing and circulating heating equipment 2 for tall and large spaces.

[0031] Heat recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com