Air drying system and working method of biomass capable of efficiently recovering waste heat

A technology for recovering waste heat and air drying, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., and can solve the problem of low grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

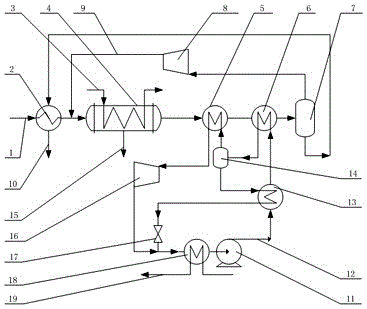

[0016] Refer to attached figure 1 , detailing the specific implementation process and working method of the biomass air drying system proposed by the present invention. The system includes two subsystems: biomass air drying subsystem and waste heat recovery organic Rankine cycle subsystem.

[0017] In the biomass air drying subsystem, the wet biomass 1 first enters the cold side of the first preheater 2 , is preheated by the condensed water 10 on the hot side, and then enters the drying box 4 . The heat source medium 3 flows through the hot side of the drying box 4 through the heat source medium channel arranged in the drying box 4, and the circulating air 4 and the preheated wet biomass 1 enter the cold side of the drying box 4. In the drying box 4, the wet biomass After the substance 1 absorbs the heat energy released by the heat source medium 3, the water evaporates and is taken away by the circulating air, while the humidity and temperature of the air at the outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com