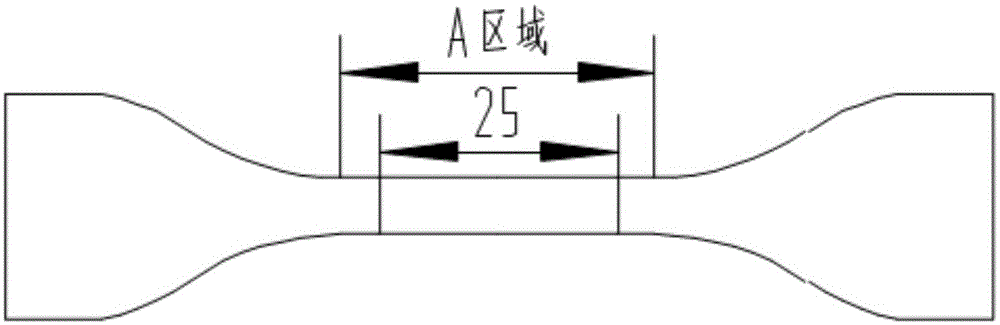

Adjustable clamp for rubber tensile set test

A technology of permanent deformation and test fixtures, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of non-adjustable fixture structure, large error of test results, and prone to disputes, so as to save test costs, ensure quality, and accurately adjust Effect of Rubber Tensile Length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

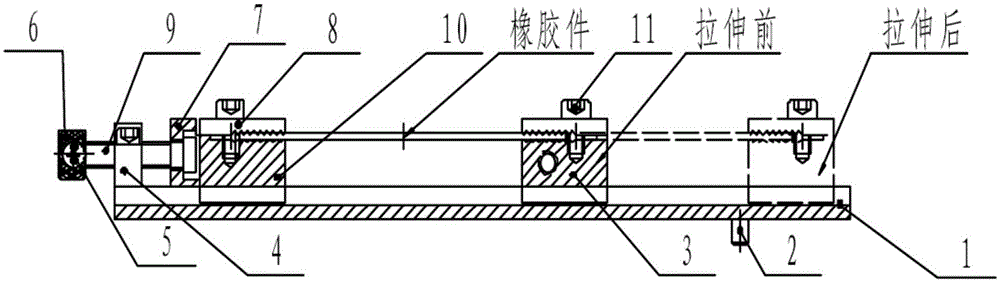

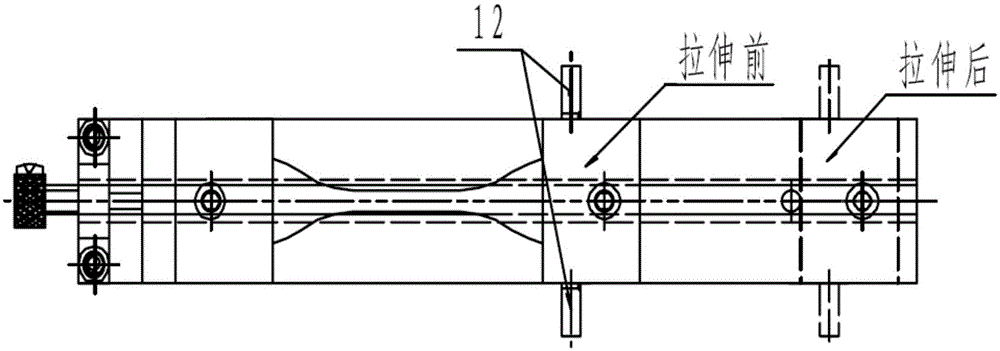

[0013] An adjustable rubber tensile set test fixture, such as figure 2 and image 3 As shown, it includes: track bottom plate 1, positioning pin 2, moving slider (coarse adjustment slider) 3, baffle plate 4, cross keyway screw 5, handle 6, backing plate 7, toothed cover plate 8, adjusting screw rod 9, Moving slider (fine adjustment slider) 10, hexagon socket head cap screw 11, tension rod 12, etc., wherein:

[0014] On the track base plate 1, there is a through dovetail groove 13 milled, which cooperates with the dovetail seat provided on the bottom surface of the fine adjustment slide block 10 and the coarse adjustment slide block 3 (such as Figure 4 shown), so that the fine adjustment slider 10 and the coarse adjustment slider 3 can slide freely on the track bottom plate; the fine adjustment slider 10 and the coarse adjustment slider 3 are all provided with a cover plate 8 through an inner hexagonal screw 11, and the In order to clamp the sample of rubber parts; in order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com