Novel tensile strength testing device for core sample

A technology of tensile strength and testing equipment, which is applied in the direction of measuring equipment, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of high cost, high time and labor costs, and inability to reuse, etc., to achieve Ease of operation and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

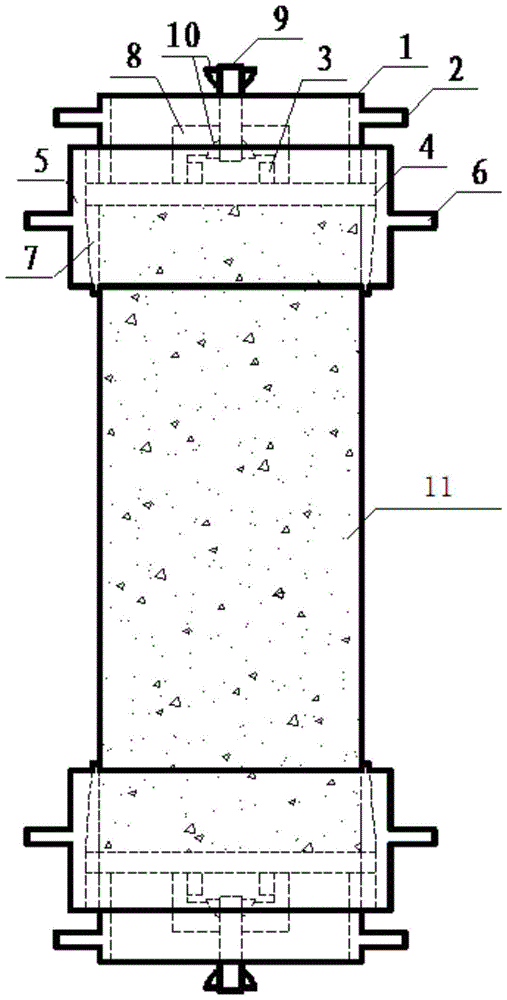

[0030] figure 1 Shown is the structure diagram of the novel core sample tensile strength testing device of the present invention, and the novel core sample tensile strength testing device includes a pull plate sleeve, a specimen fixing sleeve, a washer 7 and a pulling device.

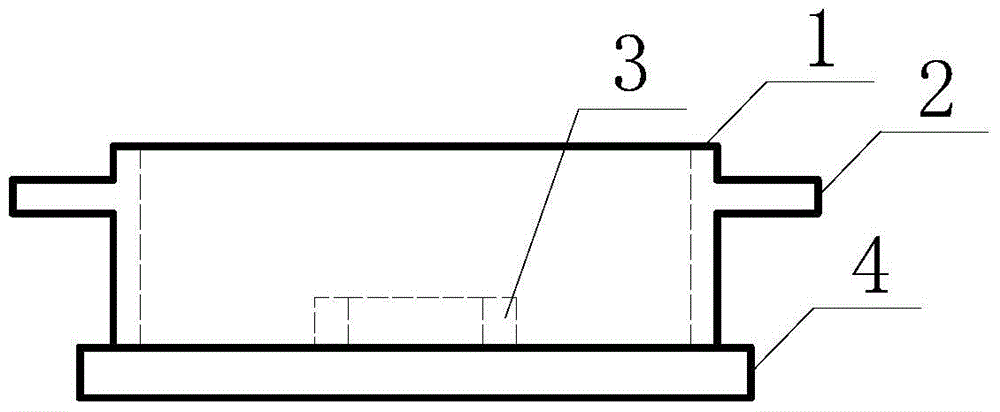

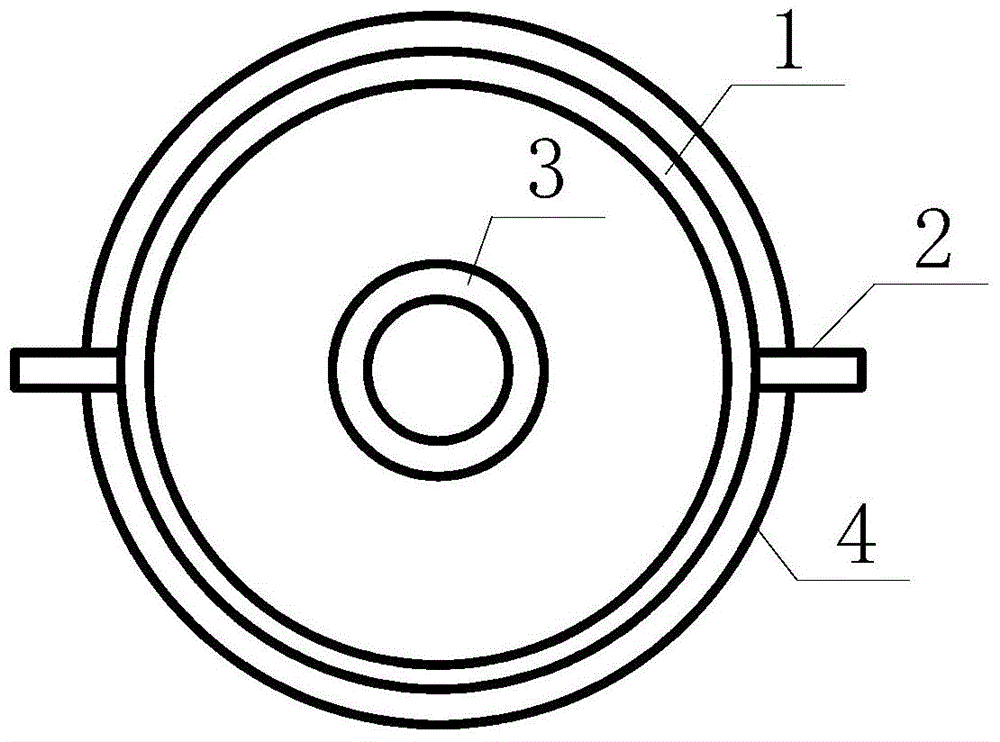

[0031] Please continue to refer to Fig. 2 (a) and Fig. 2 (b), the sleeve with the pull plate includes a steel ring 1, a handle 2 located on the outer wall of the steel ring 1, an outer wire pressing plate 4 connected to the bottom of the steel ring 1 and A small steel ring 3 with an outer wire located inside the steel ring 1 and connected to a pressing plate 4 with an outer wire. The outer wall of the steel ring 1 is provided with a handle 2 (handle 2 can be welded on the outer wall of the steel ring 1), the handle 2 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com