Transformer oil temperature monitoring system with temperature prediction function

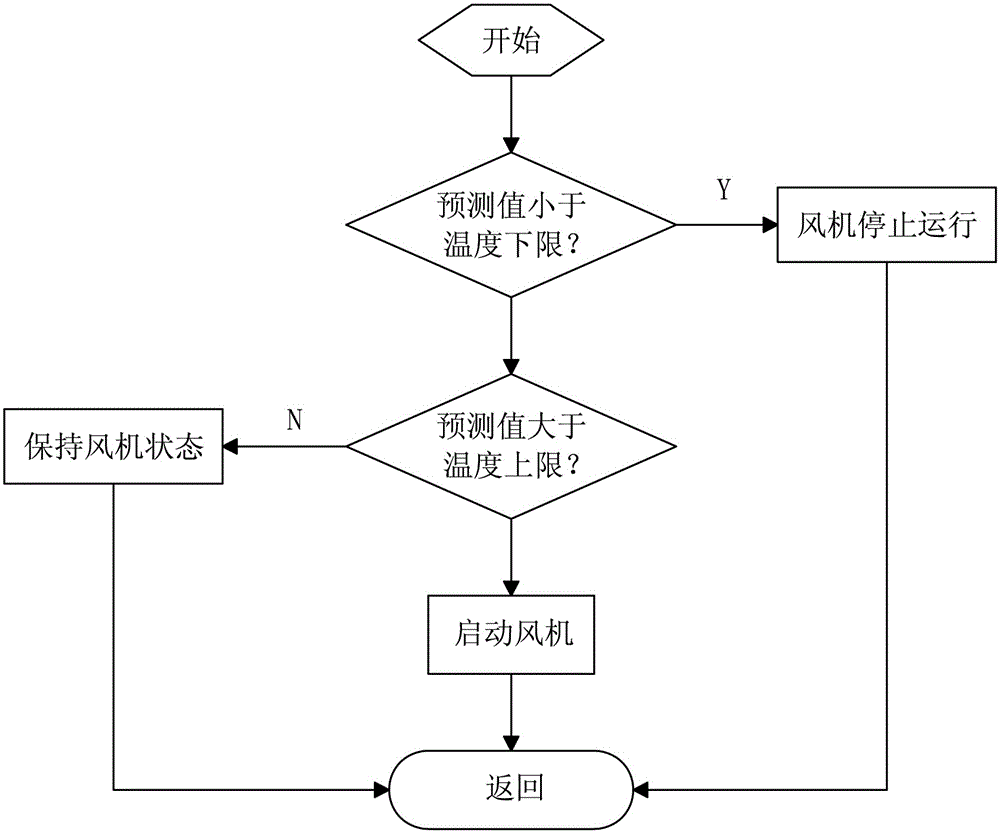

A technology of transformer oil and monitoring system, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of frequent startup of cooling fans, affecting the stability of the fan life system, etc., to solve the problem of oil temperature runaway and reliable Good performance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

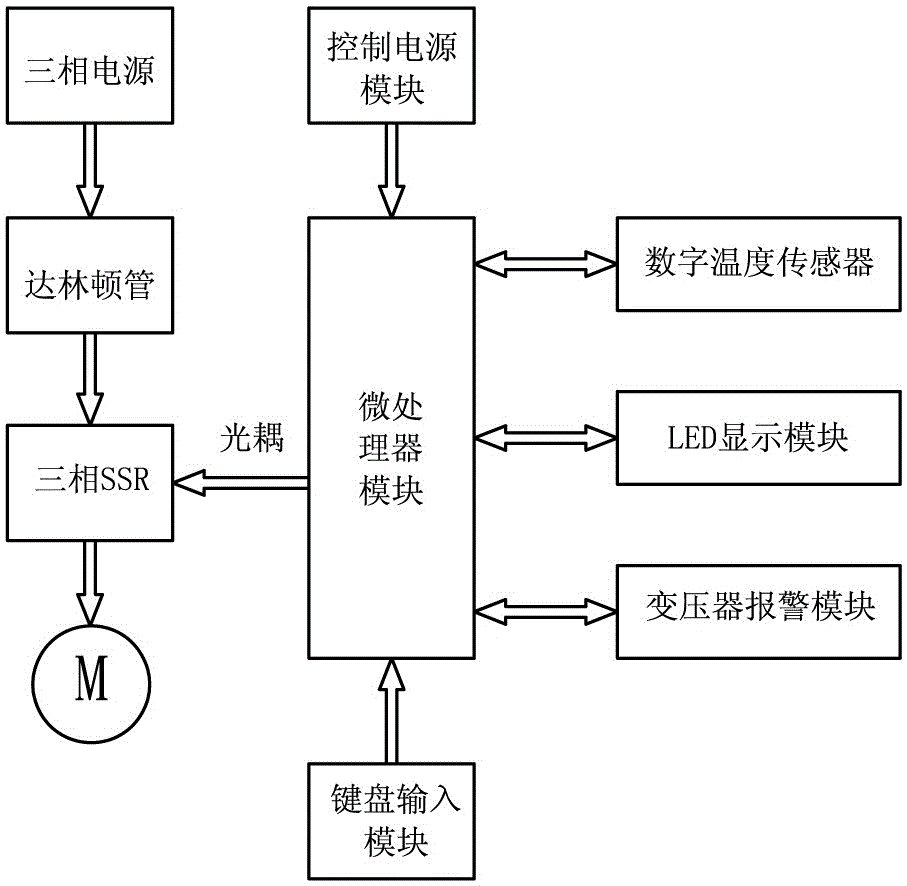

[0040] like figure 1 As shown, a transformer oil temperature monitoring system with temperature prediction function, which includes:

[0041] The digital temperature sensor collects the top layer oil temperature value of the transformer oil tank; the digital temperature sensor can adopt the DS18B20 single-line digital temperature sensor of the U.S. DALLAS company to realize the signal acquisition function of the transformer top layer oil temperature;

[0042] The microprocessor module is connected with a digital temperature sensor, receives the transformer top layer oil temperature value collected by the processing digital temperature sensor, and outputs a cooling control signal or a cooling control signal; when specifically designed, the microprocessor module adopts ATMEL The AT89S52 single-chip microcomputer designed by the company, DS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com