Stockyard environmental-friendly monitoring and sprinkling dust reduction pre-control system

An environmental protection monitoring and storage yard technology, applied in the direction of control/adjustment system, non-electric variable control, and simultaneous control of multiple variables, can solve problems such as manual constraints and influences, and achieve improved work safety, improved working conditions, and control instructions evidenced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

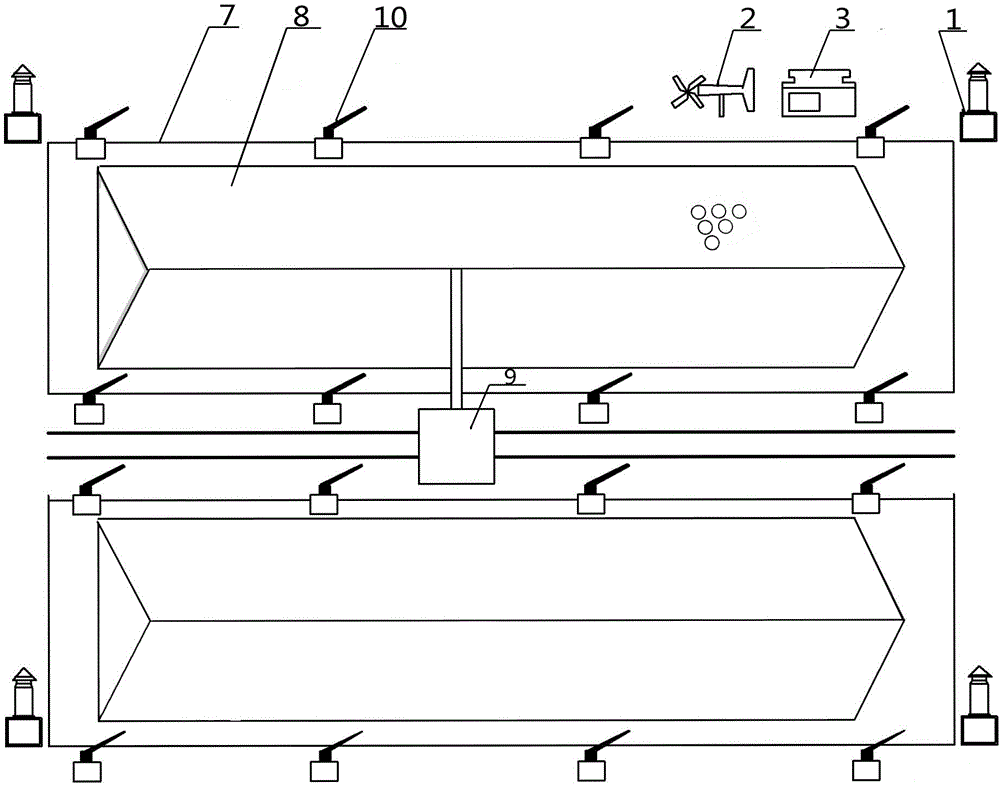

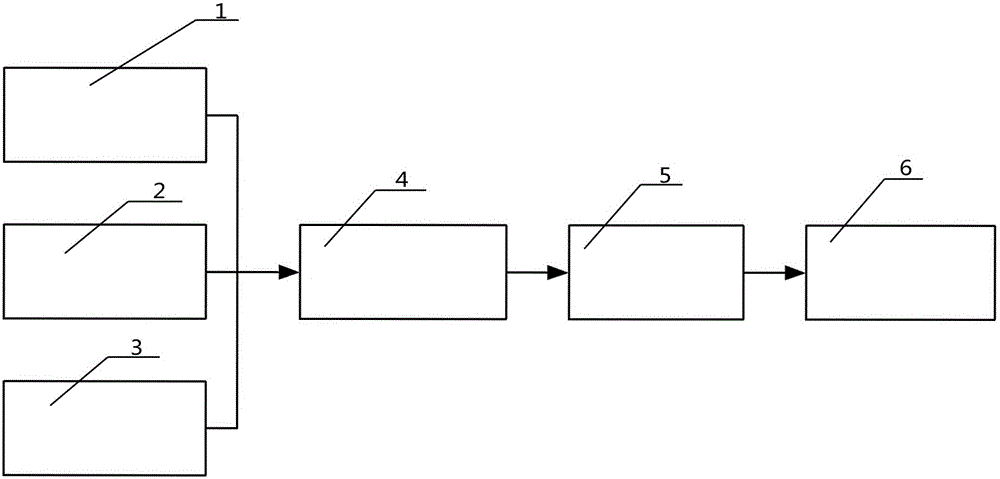

[0016] See figure 1 A storage yard environmental protection monitoring and sprinkler dust reduction pre-control system shown includes a dust concentration real-time detection device 1, an anemometer 2 and a temperature and humidity sensor 3, and the dust concentration real-time detection device 1, anemometer 2 and temperature The humidity sensors 3 are respectively connected with the detection control computer 4, and the detection control computer 4 is connected with the PLC controller 5, and is connected with the sprinkling and spraying equipment 6 through the PLC controller 5. Therefore, using the detection system composed of the dust concentration real-time detection device 1, the anemometer 2 and the temperature and humidity sensor 3, after obtaining various detection signals, the detection data is transmitted to the detection control computer 4 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com