Composite cable and production technology thereof

A composite cable and production process technology, which is applied in cable, insulated cable, cable/conductor manufacturing, etc., can solve the problems of reducing signal transmission strength, affecting normal use of users, and interfering signals, so as to improve the scattered distribution of cables, The effect of shortening the production cycle and improving the production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

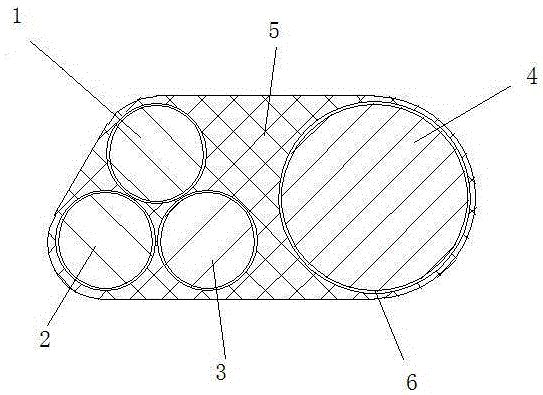

[0036] as attached figure 1 As shown, the plastic insulating sleeve is divided into two regions by a separation layer, and the thickness of the separation layer is greater than the thickness of the surface layer of the plastic insulating sleeve. The data transmission wires and power supply wires are respectively placed in the two areas, and there are wire holes corresponding to the wires. The structural form of the composite cable is integrated through the plastic insulating sleeve, which improves the problem of scattered cables during the building construction process.

[0037] In the production process, a layer of shielding layer is pre-coated on the finished network cable, TV signal line, telephone line and power supply line. The shielding layer can shield the electromagnetic field generated by the current passing in the cable, and can also play A certain grounding protection function; pass the network cable, TV signal line, telephone line and power supply line covered wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap