Inner isolation channel forced accelerated circulation transformer

A technology for accelerating circulation and transformers, applied in the direction of transformer/inductor cooling, etc., can solve the problems of affecting work efficiency, affecting heat dissipation, and increasing losses, and achieves the effects of improving heat dissipation efficiency, increasing convection speed, and increasing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

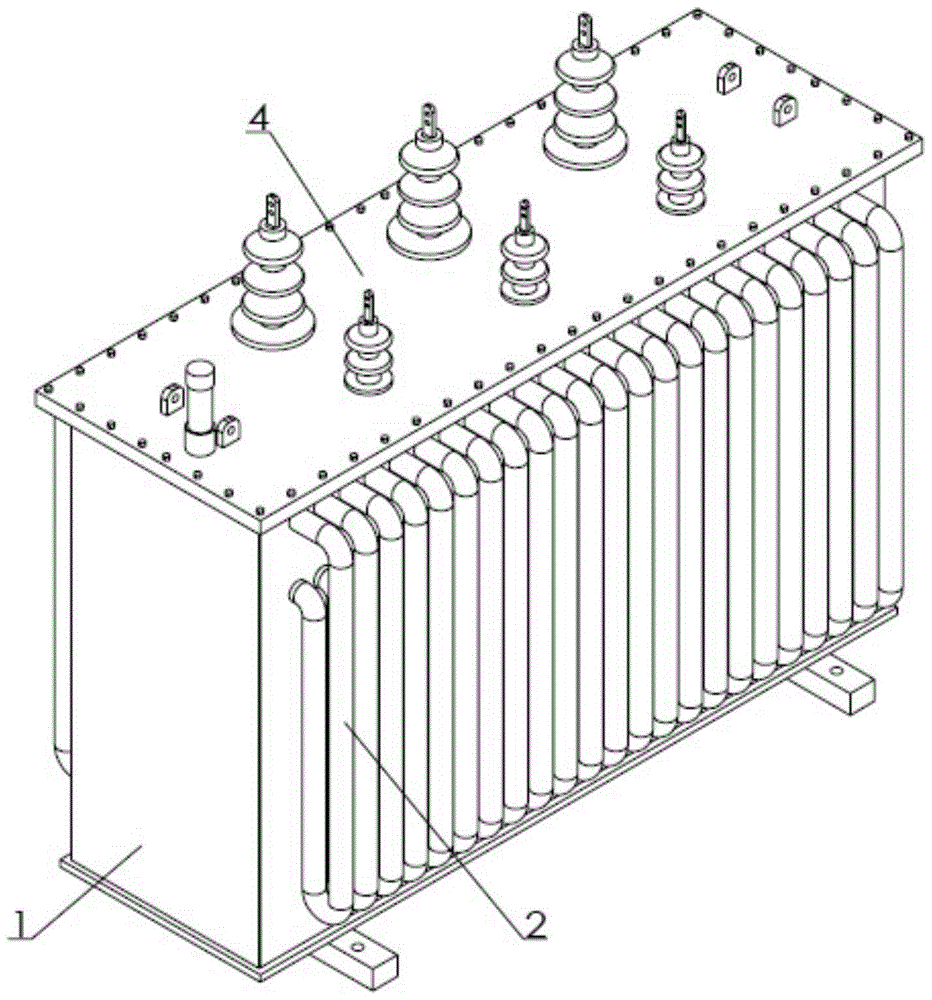

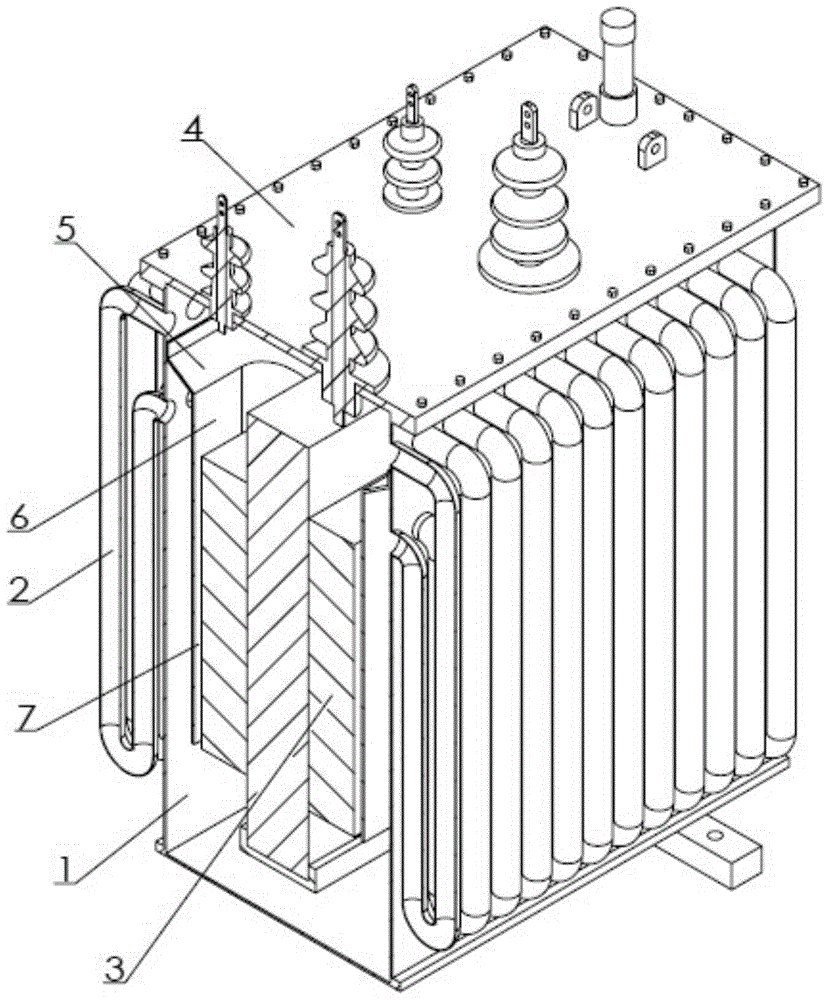

[0012] Embodiments of the present invention are as figure 1 , 2 As shown, the forced accelerated circulation transformer with internal isolation flow channel is provided with a transformer oil tank 1 and a heat dissipation pipe 2, and an iron core winding 3 is arranged in the transformer oil tank, and the distance between the upper part of the iron core winding and the upper cover 4 of the transformer oil tank is not less than the height of the transformer oil tank One quarter, the upper part retains a space for high-temperature oil, and the side wall of the transformer oil tank is provided with a transverse partition 5 extending inward. The coaming plate 6 with a distance from the bottom of the transformer oil tank, the upper edge of the coaming plate meets and connects with the inner edge of the transverse partition, the space between the coaming plate and the winding forms a flow channel 7, and the distance between the coaming plate and the winding is 0.5 cm to 1.5 cm, Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com